walls walls walls

Posted

Inactive Member

Les

Devon Junction

Kernow Junction

Kernow Junction

Posted

Guest user

Mike

Posted

Full Member

Phill

Posted

Guest user

She may start to wonder if he is actually supplying other clients who use latex rubber a lot :shock: :shock: :shock:

cheers Brian.W

Posted

Full Member

Phill

Posted

Guest user

BTW, if you are doing any N scale stuff let me know :D

Posted

Guest user

I do this when using filla for roads etc. the plaster i am using dries in 6 minutes so you have to be quick.

Ok a quick update

I have now made 5 moulds from walls I have made. They need a bit of a trim but look to be able to do the job. The masters I have are a compressed sponge type material, these are flimsy under pressure. I snapped the wall last night when removing a mould. The retaining wall (with arches) are two sheets stuck together. This came apart at my first attempt. I may make a mould of just the arch which can then be added to the wall.

I have been looking online and I have come up with a master plan. You can buy the following

80mm wall panel

40mm wall panel

Piers 40mm 80mm

End columns

Inclines low high, high low

Dhrystone wall

I think this will be the way forward, making a mould package of 8 moulds so people can mix and match and build low and high walls. I think selling them as a package would be better.

Ok here we go

GUINEE PIGS WANTED

I would like 4 volunteers; this will not cost you anything…

All I want is an opinion on the moulds I have produced so far. This is a basic wall as pictured above. All I ask is within a week you can make a couple of walls chuck some paint on and tell me what you think of the mould, the postage (wrapping etc). I will pay for postage so UK residents only (sorry) so all it will cost you is a couple of hours to make a wall or two, I don’t want the moulds back so if you don’t like them tell me why and you can use the mould as a fly swat or something. If you are interested I will take the next 4 posts and then PM you giving you my email to send your address to. I will pack the moulds over the weekend and post them on Monday.

Posted

Legacy Member

Posted

Full Member

Cheers

'

Posted

Guest user

I've got a box of Woodland Scenic's moulding plaster just waiting to be opened :!: .

Posted

Full Member

Phill

Posted

Guest user

the hunt for guinee pigs is now over.

i will update this thread once i have recieved feedback.

Posted

Guest user

1 4x high wall 80mm

2 4x butt rest 80mm

3 1x corner 80mm

4 4x low wall 40mm

5 4x butt rest 40mm

6 1x corner

7 low wall to high wall

8 high wall to low wall

9 high wall to 120mm

10 120mm to high wall

11 sleeper fence

12 pavemants x 8

13 pavement corner x4

14 pavement end x4

15 1x drystone wall

16 1x drystone wall with gap

17 drystone wall gate posts

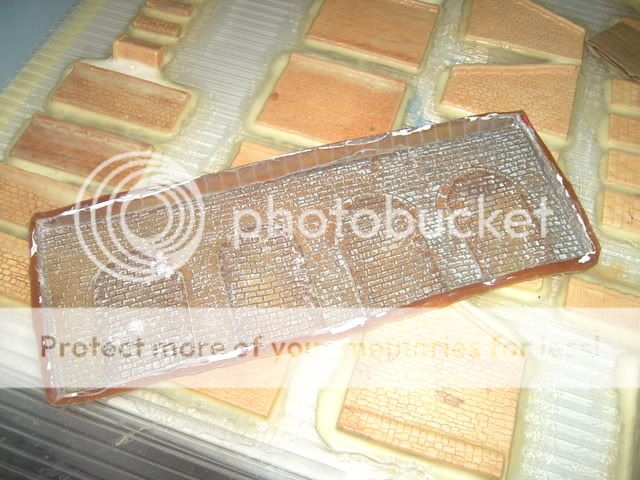

here is the result whilst the mould is setting

and one from a retaining wall i done earlier

i will ship these out to the guinee pigs once i have 3 sets

Posted

Legacy Member

Posted

Guest user

I should explain to the wider membership, that I've had a delivery of the first wall and the mould looks excellent. I'm due to do a casting this week(probably Tuesday) and will post the results on here as well as sending a PM to Matt :!:

Posted

Full Member

'

Posted

Full Member

Well i made one and thought what if i dont want this size, so i cut some wood to size and sectioned part of the mould to give me the size i wanted. Then i heard that one broke for someone else and i thought of a idea. I poured some plaster into the mould and then laid some chicken wire into it and poured some more on top. Also incase it stuck to the mould i laid talcom powder on the mould before i commenced pouring (do not go there with the talc :evil: , its the wifes), this stopped it sticking when it had dried. I must say when i took it out it felt very good and strong. The detail is excellent as well. Painting will be done at weekend and i shall try and picture the steps i do when i make another.

I am ejoying this as well, i feel as thou i am a modeler now :D all be it a naff one :D

Phill

1 guest and 0 members have just viewed this.