00 Gauge - Devan and Summersett V4

Posted

Inactive Member

Max

Port Elderley

Port Elderley

Posted

Guest user

Time will tell once I get it motorised late Nov/early Dec. Anyway, gaping holes on the ground is the going thing now. ;-)Are you sure you know what you're doing, Sol? That looks like a very big hole. :shock:

Posted

Full Member

Just let me have the dimensions next time and I'll send it Airmail.

Posted

Guest user

Warning: Some posts may contain humour

**********************************************

Please send me an assortment of holes, those not suitable will be returned.

Posted

Full Member

I have some very nice black holes (including the Studio at the moment where I had sudden instructions to clear the kitchen table).

Posted

Guest user

Do these holes, of varying dimensions, come with "sky-hooks" attached to help retain said holes in-situ and is there a recommended number of "sky-hooks" per hole and are the "sky-hooks" re-usable after the holes are filled-in? Just asking,

Kind Regards,

Michael Thornberry.

PS:- Do these "sky-hooks" also vary, in size, dependant on hole-size?

Posted

Guest user

Posted

Guest user

Wiring now back to panel which will need some mods. ( splitting time between this & centre peninsula)

Posted

Guest user

The microswitch you are using is that a standard one bought from an eletronic bits supplier?

Brian

Posted

Guest user

I assume all your points are electrofrog Ron Yes

The microswitch you are using is that a standard one bought from an eletronic bits supplier? like this one

I am using live frog as I connect a LED across it to indicate track selected is powered as mentioned in other posts of mine.

Posted

Full Member

In your last post you indicated

I am using live frog as I connect a LED across it to indicate track selected is powered as mentioned in other posts of mine.

Do you have a post link for this and have you included a wiring diagram

CC Weathering Services: https://ccgwr1.wixsite.com/ccweatheringservices/

CC Weathering Services Facebook Page: https://www.facebook.com/ccweatheringservices/

CC Weathering Services Facebook Page: https://www.facebook.com/ccweatheringservices/

Posted

Guest user

Posted

Guest user

Four points, one single slip & two 3-way and are operated via slide switches

Because these points are not easily seen in how they are set, I added some LEDs into the tracks but they still cause confusion especially the two 3-way points for the operators who only work on the layout fortnightly ( OK for me coz I use them, most days) so after another Op session today, it does seem that I will have to motorise the points & provide an additional panel with push buttons with LEDs in the panel instead of in the tracks.

Two points - hand made , will need to be replaced with Peco to provide tiebar locking.

In fact some simplification is possible.

Posted

Guest user

Sounds a bit drastic Ron. Couldn't you use SEEP PM4 solenoids or Tortoise/Cobalt/Fulgarex/Lemarco motors that self latch?… Two points - hand made , will need to be replaced with Peco to provide tiebar locking. …

Cheers

Dave

Posted

Guest user

Posted

Legacy Member

The furthest reach into my corners is about 28"and that's far enough.

Posted

Guest user

Posted

Legacy Member

Posted

Guest user

Started now, replaced two hand made units with Peco & motorised them. Removed one point where the tanker is sitting & made the single slip into a conventional point - pinned one set of blades across & the modified slip now works in parallel with the entry point also now motorised. Couple more motors & a panel ( which is half built to go.

The DMU tracks will be moved further apart to allow for a fuelling platform similar to what I have seen on another forum / Bachmann unit http://www.ehattons.com/StockDetail.aspx?SID=24629

Posted

Guest user

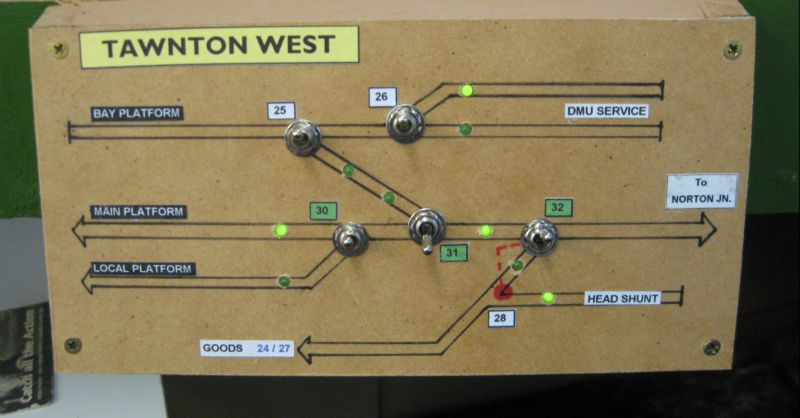

I was going to operate using pushbuttons & diode matrix but had the problem of frog switching for the two 3- way points so I use Masterswitch V1 units which provide a pulse of power but are activated via a toggle switch so the other half of the toggle does the frog switching. This is the panel

The LEDs are connected across the track & DCC power is used. Point 28 is operated as a crossover with 32 so only one switch required as 28 has a dead frog.

Back to an operating session next week.

1 guest and 0 members have just viewed this.