Uncoupling with Neodymium magnets

Posted

Full Member

Doofer has a play....

Hi Dooferdog,Nice work. Have you thought about putting Kadee #s 17-20 (depending on the distance required) rather than messing around soldering iron wire to the tension locks? Most new wagons and coaches are already equipped with NEM pockets (yours are in the photograph), if not Parkside Dundas has the mounts for them, Bachmann has the bendy bits attached to tension locks. Kadee also sell under-the-track oblong magnets that fit under the sleepers and ballast and that have a magnetic field appropriate for the coupler. The magnetic field of such a small neodinium magnet wiil mean some very precise shunting, an oblong magnet is quite forgiving with respect to positioning, having a magnetic field some 2" long. Kadees are way overpriced in Europe (200%), get them from the US by mail order or from an international eBay seller. Kadees are also easily modifiable - see DCC Uncoupler. I'm seriously looking at this method as my stock is 100% Kadee equipped and I want some variety in shunting operations.

One disadvantage of the magnet system is that decoupling can only take place at one place. Ideal for running around a coach, not so good in the shunting yard. If you want to stick with tension locks there is a kit for installing a controllable tension lock in the tender (or in a tank engine with space in the bunker, or a van or truck with a load, DCC control). Keen Systems. It works, I have one.

One thing I did when using tension locks was to cut off most of that descending arm - unless you're using one of those manual decoupling ramps it's superfluous, especially as you have more than enough counterweight with the iron wire. It's amazing how much difference it makes visually.

Nigel

©Nigel C. Phillips

Posted

Guest user

I've just ordered some 4 mm circular magnets 1.5 mm thick……..but screwed up somehow on the pull strength …… The version I have ordered is 0.36 kg. :hmm

Don't ask how I done it as I was looking at the 0.14 kg version but must have taken my eye of the ball. Is this going to give me a problem ?

Cheers

Toto

Posted

Full Member

Toto, I don't know, I got mine given to me and don't know the pull strength…. If it seems too muc the I'd cut the length of the doofer a bit. One good thing about this idea is that stock can't freewheel out of a siding etc, the steel of the axles keeps a very light hold on the wagon. Additionally, if the pull is too too much, insert them into the baseboard a little, the force of a magnetic field drops very quickly as the distance increases.

Doug

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Inactive Member

N gauge uncoupling - a new(?) method - suitable for other gauges too. - Layout Design, Trackwork & Operation. - Getting You Started.

Ken.

'It don't mean a thing if it ain't got that Swing'

Posted

Full Member

http://www.modelrailforum.com/forums/index.php?s=7affdeb774c44dee6dcbfcd83dce838a&showtopic=8094&st=0

Please note that the couplings must be Bachmann, not Hornby or Dapol. This is because Bachmann, unlike the other two, make the hook and dropper part from a metal which cannot be magnetised, therefore only the staple is pulled down by the magnet, which in turn lifts the hook. With the other makes the whole assembly is attracted to the magnet and, therefore, it doesn't work properly. Of course this is not a problem with NEM couplings. Just replace the Hornby and Dapol couplings with those made by Bachmann.

Terry

Last edit: by col.stephens

Last edit: by col.stephens

Posted

Full Member

I have fitted the Kirby system to most of my rolling stock. It works OK, but I am not entirely happy with it. The first problem I have is that on my layout it is often quite hard to see exactly where to position the wagon/loco, especially if you are not side on to it. I have tried putting down markers with some success. Second the magnets are strong and the wagon that has been uncoupled rather unrealistically locks into position being held by the magnets.

That said, it is a simple and fairly reliable system and well worth having a play. I had to change all of the couplers on my Hornby stuff, which is quite easy if they have NEM pockets, but not so with older items.

At the moment I am experimenting with Kadee couplers which is probably what I will end up using.

Bob

Posted

Full Member

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

Bob,Hi Doofer,

I have fitted the Kirby system to most of my rolling stock. It works OK, but I am not entirely happy with it. The first problem I have is that on my layout it is often quite hard to see exactly where to position the wagon/loco, especially if you are not side on to it. I have tried putting down markers with some success. Second the magnets are strong and the wagon that has been uncoupled rather unrealistically locks into position being held by the magnets.

That said, it is a simple and fairly reliable system and well worth having a play. I had to change all of the couplers on my Hornby stuff, which is quite easy if they have NEM pockets, but not so with older items.

At the moment I am experimenting with Kadee couplers which is probably what I will end up using.

Bob

Why not just replace your magnets with something weaker? Brian Kirby suggests those magnets obtained from cupboard catches.

Terry

Posted

Full Member

[user=11]Novice[/user] wrote:Bob,Hi Doofer,

I have fitted the Kirby system to most of my rolling stock. It works OK, but I am not entirely happy with it. The first problem I have is that on my layout it is often quite hard to see exactly where to position the wagon/loco, especially if you are not side on to it. I have tried putting down markers with some success. Second the magnets are strong and the wagon that has been uncoupled rather unrealistically locks into position being held by the magnets.

That said, it is a simple and fairly reliable system and well worth having a play. I had to change all of the couplers on my Hornby stuff, which is quite easy if they have NEM pockets, but not so with older items.

At the moment I am experimenting with Kadee couplers which is probably what I will end up using.

Bob

Why not just replace your magnets with something weaker? Brian Kirby suggests those magnets obtained from cupboard catches.

Terry

That's not a bad idea as the Neodymium types are really too powerful for the job in hand. I will give that a go.

Bob

Posted

Full Member

Nigel

©Nigel C. Phillips

Posted

Full Member

'Petermac

Posted

Full Member

I used 1/2" regular duty steel staples for this, and some Bachmann narrow tension lock couplers with NEM shafts. The black finish on the lower arm of the hook was removed with #600 emery paper, given a wipe with IPA, and tinned with 145°C solder using no-clean flux. One end of the staple was curved slightly (to match the profile of the tension bar) and the other straightened. The staple was cleaned with IPA, held in place on the lower arm and soldered up. The arm was then bent so that it was at the appropriate distance from the track bed. This was eyeball and nudge, those interested in doing lots will of course develop the appropriate distance standards. Painted-up matt black, left to dry and then tested.

I used a Kadee under the track uncoupler for testing. The magnetic poles are at the edges, all the better to swing the Kadee actuator arms. Problem No. 1. Nothing happened. (which I had been expecting). The lower arm was cut off below the soldered wire, cleaned up with a needle file, it now worked. The arm is steel, there is a magnetic underneath, it stops the staple wire arm from descending. Cut off it works as expected. The use of large diameter wire is why this works when the arm is left in place. I bent the arm laterally towards the wheels to give better proximity to the magnetic field. The opposite arm of course should be bent the other way. The curve in the staple end stops the arm from going to high and the actuating arm hitting the sleepers. It sits in the indentation on the underside of the tension hook. Problem No. 2. (which I have experienced before): Short wheelbase stock is attracted to the magnets - steel axles and wheels (below the finish). This would not apply to plastic axles and wheels. Something to be aware of, especially with neodymium magnets next to the rails.

Making one of these the second time took 5 minutes, I could probably get it down to 3 minutes on a production line basis. Inserting a Kadee with NEM shafts takes probably 10 seconds (at most).

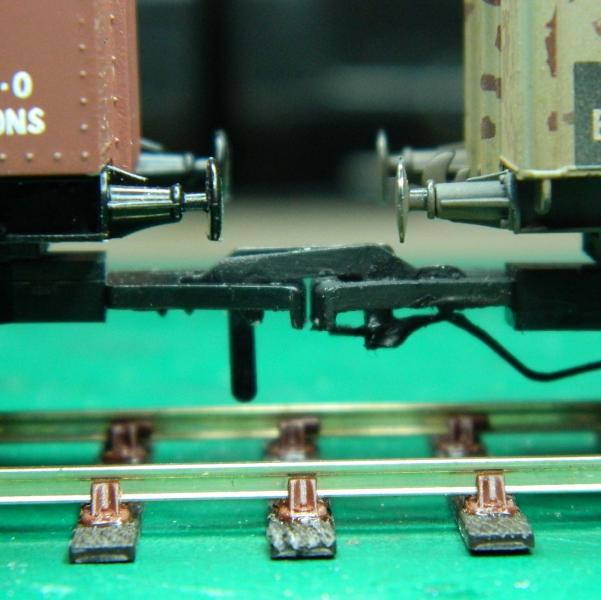

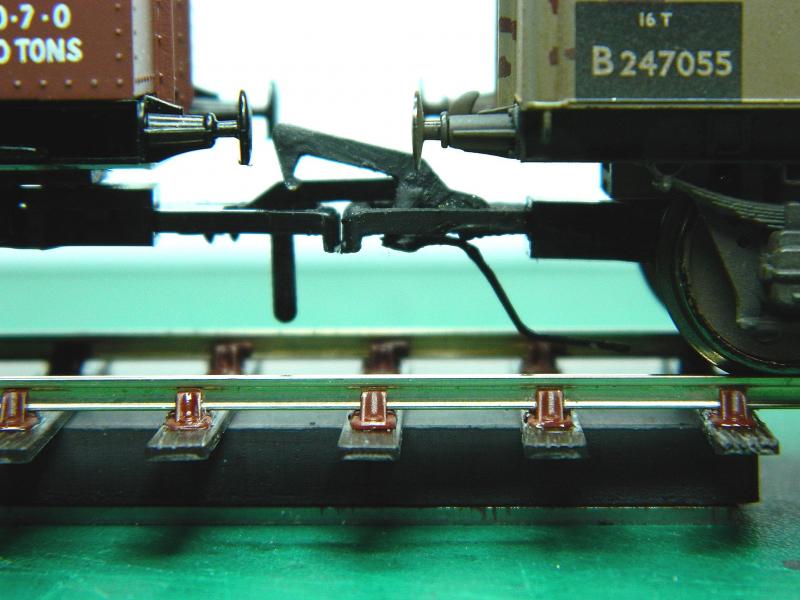

Regular Bchmann tension lock on LHS, modification on RHS. Getting rid of that hook arm helps the appearance, as well as the use of staple wire for the actuating arm.

Kadee No. 17 and No. 18 for comparison. These couplers are underslung in that the arm is below the knuckle. Note the reduction in space between the buffers compared to the tension lock couplers.

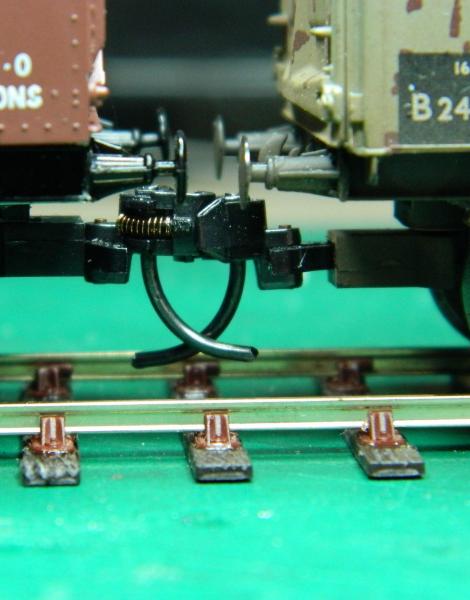

Modified tension lock between magnets.

And over the magnet.

Interesting approach, I'm glad I tried it. However, I'll stick with Kadee's for the future.

Nigel

©Nigel C. Phillips

Posted

Guest user

Excellent, I'm still playing with some of this in my mind ( I'm not the quickest to absorb these things ) but I think I can understand that. Thanks for the pictures.

Cheers

Toto

Posted

Full Member

It's all relative - £117 for a Howes decoder, £85-150 for the engine, and in my case another £20-50 for the EM wheel set, why skimp on the couplers? I'm not sure that $7-8 CDN (or less for the non-NEM's) for 2 sets (2 wagons/carriages) is actually expensive when my time is factored in and when the motive power is considered. Plus they shunt reliably. I know Kadee's are expensive in Europe, order them in bulk from a US supplier.

Nigel

©Nigel C. Phillips

Posted

Full Member

As Toto said, very interesting indeed but as you say, when you've factored in the time element, Kadees do look attractive. :roll:

I've also noted your comment about buying them direct from the States. I might do a trial order to see what reaction it provokes from the French authorities - I've had problems in the past with items from the US - although having them shipped to the UK from there has never been an issue……………:hmm

'Petermac

Posted

Full Member

The neodymium magnets came yesterday, I spent 30 minutes this morning experimenting with Kadee fitted wagons (and head to head with Kadee under the track magnets). As I suspected, the field on a 1/4" magnet (even without its intensifier plate) is too strong and too focused. The magnets worked fine when directly underneath the actuating pins (and almost touching), and there the wagons stayed, ends in the air. Move them 3 mm laterally and nothing. When I finally did manage to get them to move the pins laterally without tipping the wagons (1.5-2.0 mm from the center line) there not enough movement to reliably uncouple. Plus, no delayed uncoupling.

Kadee magnet worked fine, except for the slight hesitancy of the wagons when moving over the magnet (UK stock, steel axles, steel wheels). Kadee axles and wheels for NA stock are of course non-magnetic. Just noticed on the instructions that Kadee give a method for moving the magnet away from the track so that it is essentially turned off.

They worked OK(ish) with the two Kirby-type couplers I built, but no delayed coupling. The wagon being pulled away had a tendency to drop its hook before being separated. An oblong magnet would be better (or a string of the circular ones).

Experiment over, Kadee's and Kadee magnets for the carriage runarounds, plus maybe one or two in the goods yard for uncoupling a rake of coal wagons. Everything else as the prototype (1:1 hand, 1:76 stock, magic wand). The pins can be simply removed when stock is not separated (a B-set for example). I think if I was using tension locks I would use the uncoupling ramps, which can be controlled by either DC or DCC as required. It would beat building all those modified uncouplers and trying to hide the magnets.

Nigel

©Nigel C. Phillips

Posted

Full Member

It may save you some time and money….

Perry

Due to cutbacks, the light at the end of the tunnel has been switched off.

Posted

Full Member

5479 entries under M, a few more clues would be useful (

). I did find lots of discussion under "Kadee" and "Kadee Neodymium" (450 topics each). Interesting reading.

). I did find lots of discussion under "Kadee" and "Kadee Neodymium" (450 topics each). Interesting reading.Neodymium magnets, as I said, have a very localized magnetic field. Kadee couplers really work best with a "sided" magnetic field, that is why their magnets (above track or below track) are long, with the maximum field strength along the longest sides.

Under-track magnets have a number of advantages over fixed magnets (neodymium or Kadee) in that a) they're invisible, b) they can be positioned either on or off, and c) with a bit of work can be made to move along the track underneath, thus allowing uncoupling where required. The big disadvantage of all these magnets is that anything powerful enough to trip a Kadee pin will interact with the magnetic wheels/axles favored by UK manufacturers, especially on short wheelbase stock. Probably one of the reasons for the reported hesitancy, something I do not get with my NA stock with non-magnetic wheels/axles.

Given that at most 3-5 magnets will be required on a medium size layout, an investment of $15.00-$25.00 doesn't seem that bad to me. It's that linear actuator that has got me worried.

Nigel

©Nigel C. Phillips

Posted

Site staff

works well for me - with the exception of Kadee electromagnets on the platform lines in my main station, the rare earth magnets as described in the thread by Perry, suit my crew done to the ground.

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

Thanks for the link. Glad to see that with some perseverance and fettling the small magnets work well. I am left with the impression (after reading all the posts) that rectangular, rather than circular, one work best. I especially liked the post about cutting Kadees into smaller rectangles.

One of the other issuers I'm facing is that I'm using code 75 track with thin C+L Finescale sleepers. Even small magnets will have to be sunk in the cork. As I'm at the track construction stage locating the undertrack magents is no hardwhip.

Nigel

Last edit: by BCDR

Last edit: by BCDR

©Nigel C. Phillips

1 guest and 0 members have just viewed this.