Ply girder frame baseboards

Posted

Guest user

Full steam ahead now a LNER layout will make a pleasant change lots of A4`s racing around.

cheers Brian

Posted

Full Member

I'm having my doubts about LNER - they were all steam and it appears, in model form at least, they don't haul too well :roll::roll:. It will be based around end of steam / entry of diesel but may well have the odd blue one or even an odd Class 66 - if I like it, I'll run it. :cheers:cheers:cheers:cheers

'Petermac

Posted

Guest user

steam loco hauling capacity does vary somewhat. If the layout is dead flat that is a great help problems really begin if there is any sort of gradient and it does not have to be a great deal to start to get the wheelspins.

Weight is the problem with our modern plastic models the old Hornby Dublo and Wrenn ones had weight as they were diecast.

Also it depends how many coaches you want to pull most mainline model locos will pull 6 coaches on a flat track easily. Yes there are exceptions and i quoted the WP Allen as an example which for some reason is particularly bad. Of course it may be possible to add weight to the loco to improve things.

Also one has to be realistic there is no way a Terrier 0 6 0 is going to pull 6 coaches and in reality the real ones probably could not.

There is no reason why your layout cant be pre war and 60s you could split the layout scenically timewise if you wanted to.

That is something i am toying with myself at the moment perhaps doing differant areas of the layout differant time periods.

It would be nice to see a group of Garter Blue A4`s sitting outside your new MPD

cheers Brian

Posted

Inactive Member

I'm surpirsed you've found yours is starting to twist. :hmm I'd have thought the ply was rock solid being laminated across both grains so, as you say, it must be "twist" rather than warp.

Problem solved Peter,:doublethumb

Photo below shows the board after I have put diagonals in using 60 x 20mm timber.

They are now rock solid and don't twist anymore. I think Jim referred to this so a big thanks for the suggestion.

I do need to put more air into the car tyres now though:hmm

Les

Devon Junction

Kernow Junction

Kernow Junction

Posted

Full Member

Cheers

Jim

Jim Smith-Wright

Rule 1 - Model what you really see and not what you think you know!

www.p4newstreet.com

Rule 1 - Model what you really see and not what you think you know!

www.p4newstreet.com

Posted

Inactive Member

Les

Devon Junction

Kernow Junction

Kernow Junction

Posted

Legacy Member

Has anyone done this type on construction before? I'd be very grateful for any hints and tips, particularly about how the hold the original curve in place to the correct shape. Is it a case of making up a dummy base and nailing some guides in position?

Posted

Full Member

Exactly the same principle but I'd assemble the "girder" in situ. Use ply certainly no thicker than 6mm. Make up your "outer" form - probably square or at least with some straight edges. Mark the length of your cross members and fit them in place - rather like the spokes of a wheel awaiting the fitting of the hub (or rim if it's the outer bit that's curved). Fix the inner side of your girder to the ends of the "spokes" (glue/screw) then fit the spacer blocks and finally, fit the outer side of the "girder".

As an alternative, Marty did an excellent laminated curved girder on his Newcastle Emlyn layout made out of MDF. That's really worth considering.

'Petermac

Posted

Guest user

One side of the mdf sheet has slots cut across the whole board about 5-6mm apart

cheers Brian

Posted

Legacy Member

Just as well I hadn't paid for it…;-)

….and thank you Peter for you tips. I'm still open minded about construction, but was going to experiment just using the outer frames with no cross bracing, but the spoked wheel idea is a possibility. One of the things I have found building the lower levels is that the 4" and 6" wide boards are very strong once built in a "U" or "I" section. I was thinking about a similar construction on the trackbed and then the U section track base once screwed to the outer frame, may actually act as stiffening and make the whole thing rigid, without cross bracing.

Once the layout section is drawn out in Templot, I print off any track that will be required on the specific board. Templot track plans have the centre line marked, so measuring out say 50mm either side of the centre line and then cutting the print to that width, means you can create a full size template. I stick this on the ply with photo mount and then cut the ply with a jigsaw to the template. I then use 4mm mdf which is cut into strips about 25mm wide. These are glued to the edge of the ply to form the U or I section. Result is a flat piece of ply which is considerable stronger and stays flat. It take 10 minutes or so for the glue to go off and then you can repeat the process for the other side. This picture shows the type of thing I mean.

Last edit: by gordons19

Last edit: by gordons19

Posted

Guest user

Posted

Full Member

I've laminated curved ply/wood items for boat bits, using epoxy resin, but PVA will do fine for an indoor jobby.

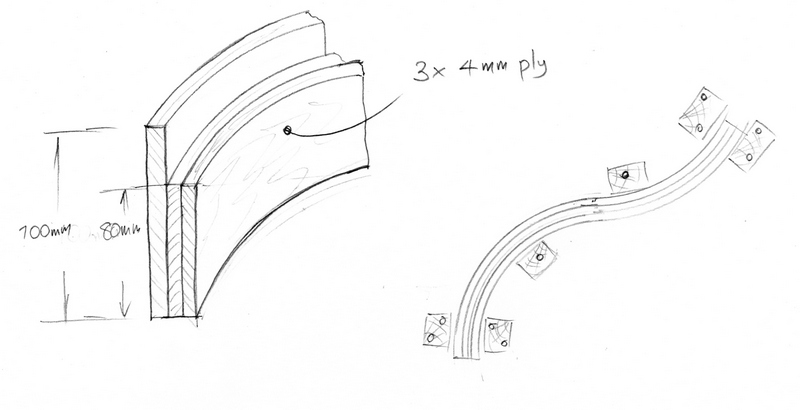

What I have drawn below is an imaginary 'grand piano shape' baseboard the edges of which which could be laminated from 3 layers of 4mm ply cut in strips. If you can only get 3-ply, cut them so that the grain of the outer two plies runs along the length of the strips to help bending.

You'll need to mark out the full size curved item on a sheet of shuttering ply, or a shed floor to which you can screw an adequate number of wooden blocks. The curve must be arranged so that the ends which are to be joined into a square corner are a little 'over-bent' as they will spring back a little.

The laminations should be overlapped for about 1/3rd of their lengths. The inner two laminations could be narrower than the outer strip so as to form a handy shelf ['landing' in boat terms] for the baseboard to rest on. You'll need to call in lots of favours to borrow as many clamps as you can, though two large penny washers on an appropriate nut and bolt can hold edges together, too.

Put polythene under the wood so that you have reasonable chance of getting it unstuck from the floor!

Looking at the standard and complexity of the work you are doing above, this should be a doddle for you. P.M. me if you need to.

Doug

Last edit: by Chubber

Last edit: by Chubber

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

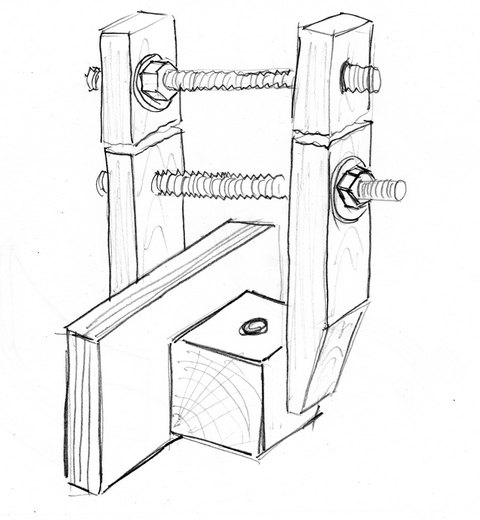

I wonder if this idea for a clamp had crossed your mind? Called 'long fingers' it is quickly and simply knocked up using threaded rod, nuts and washers with a bit of scrap wood. It can save having to buy an expensive , possibly large clamp that you may hardly ever use, too.

Doug

Doug

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Legacy Member

Your experience and sketches are absolutely invaluable…:doublethumb

Posted

Full Member

It's the same idea as Marty's MDF laminates on his curved incline but, if I remember correctly, his laminates made up into the track bed rather than framing for the boards. The "upstand" is something I hadn't thought of but gives the baseboard a smart and durable edging.

Those "long fingers" are also very useful - I've used them many, many times in the past. A doddle to make and they can be almost any length you choose. :thumbs

'Petermac

Posted

Full Member

Just in case someone wants to have a look at the laminated roadbed that I use on my L-Girder baseboard the first page of the Pentrecourt Halt diorama is here:It's the same idea as Marty's MDF laminates on his curved incline but, if I remember correctly, his laminates made up into the track bed rather than framing for the boards.

http://yourmodelrailway.net/view_topic.php?id=1661&forum_id=52

… and from the 56th post to the bottom of the page here in my Newcastle Emlyn layout.

http://yourmodelrailway.net/view_topic.php?id=362&forum_id=21&page=3

The whole baseboard structure is very strong… no idea how heavy it is, never tried to lift it. Like Petermac, more "moveable" rather than mobile.

HTH.

Posted

Legacy Member

I'll make some time later today, to read the threads as I'm sure there are some real gems there. As a newcomer I have been amazed at some of the work from a year or two back that occasionally bobs up to the surface. The quality of the work and the appreciation from other members is a joy to behold.

It's a real pleasure to be part of this group…..:cheers

Posted

Full Member

Marty, many thanks for pointing me towards your layouts. I've had a quick look and the first thing that struck me was the real quality of your woodwork. Some real craftsmanship there…..:thumbs

I'll make some time later today, to read the threads as I'm sure there are some real gems there. As a newcomer I have been amazed at some of the work from a year or two back that occasionally bobs up to the surface. The quality of the work and the appreciation from other members is a joy to behold.

It's a real pleasure to be part of this group…..:cheers

cheers mate

More than welcome

Enjoy.

Posted

Full Member

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

Last edit: by Chubber

Last edit: by Chubber

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

1 guest and 0 members have just viewed this.