Diesel Refuelling Point

Posted

Full Member

Another quart in a pint pot!

Hello Ed,Ed said

If only I was more mobile Terry, I wouldn't mind a trip to Kent.

Why probably last exhibition invitation?

Ed

From “Post #289,474”, 20th January 2024, 2:30 PM

Four feet of mdf isn't going to set the world alight!

Terry

Posted

Site staff

col.stephens said

Hello Ed,Ed said

If only I was more mobile Terry, I wouldn't mind a trip to Kent.

Why probably last exhibition invitation?

Ed

From “Post #289,474”, 20th January 2024, 2:30 PM

Four feet of mdf isn't going to set the world alight!

Terry

From “Post #289,476”, 20th January 2024, 2:36 PM

True, but four feet of modelling is better than forty feet of 'not much to look at'.

Ed

Posted

Full Member

I have just been reading your thread on Latton Fields. Did Latton Street ever get off the ground?

Terry

Posted

Site staff

col.stephens said

That's true Ed.

I have just been reading your thread on Latton Fields. Did Latton Street ever get off the ground?

Terry

From “Post #289,504”, 22nd January 2024, 1:18 PM

No, unfortunately Latton Street succumbed to my health (arthritis), a couple of family bereavements and life in general causing a lack of mojo.

My new N gauge layout hasn't get a name yet though

Ed

Posted

Full Member

Terry

Posted

Site staff

Ed

Posted

Full Member

Terry

Posted

Full Member

Terry

Last edit: by col.stephens

Last edit: by col.stephens

Posted

Full Member

Last edit: by col.stephens

Last edit: by col.stephens

Posted

Full Member

Last edit: by col.stephens

Last edit: by col.stephens

Posted

Full Member

The only answer is to make them yourself. I mulled it over and formed a plan. The following items were produced after a rummage through various boxes..

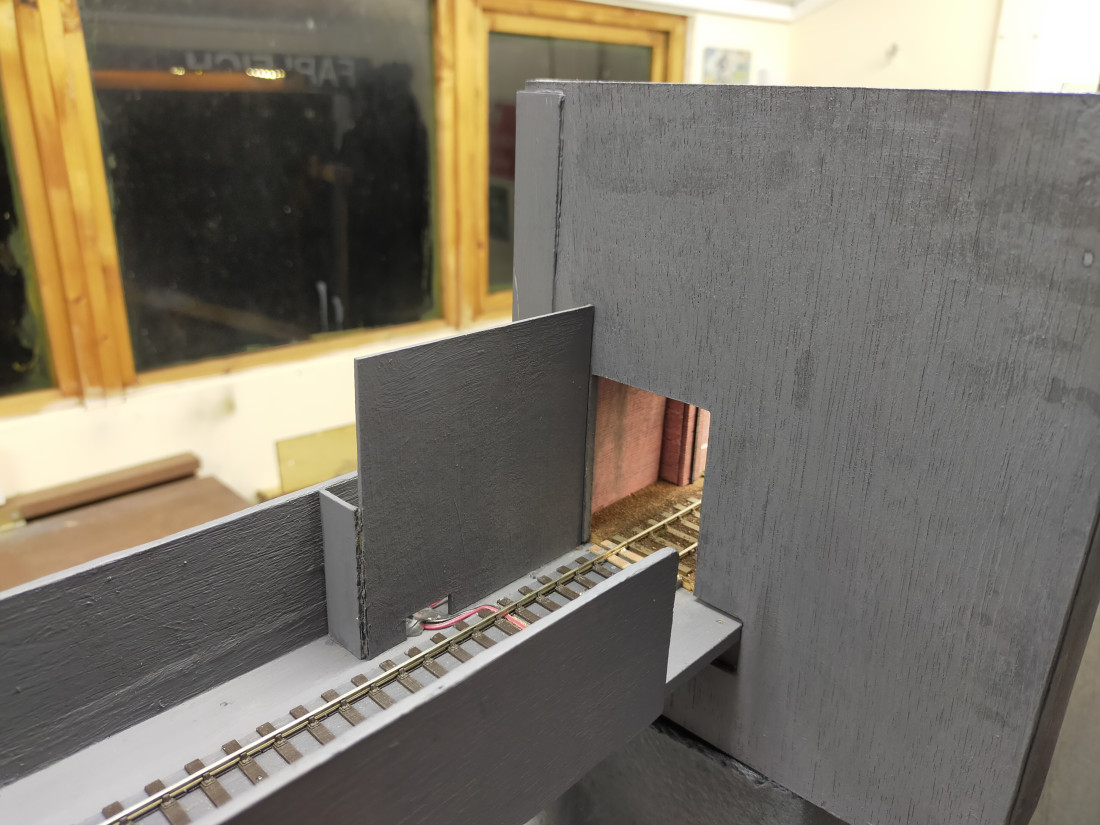

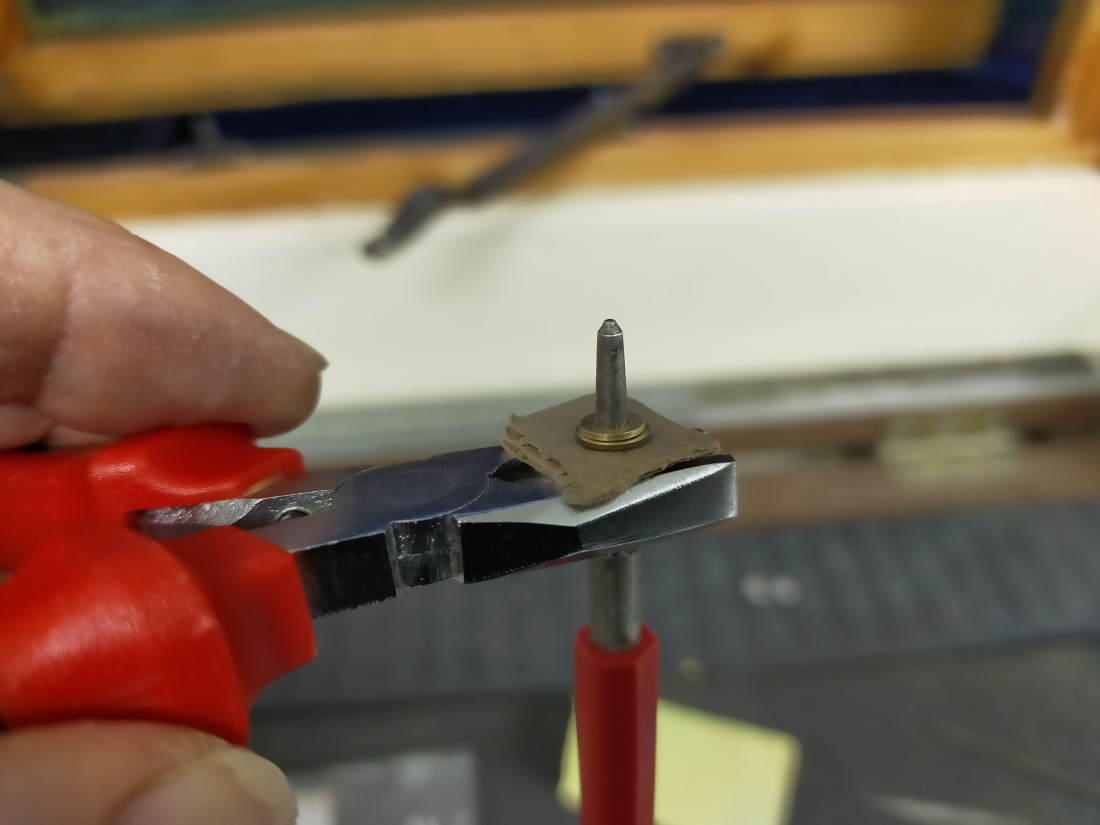

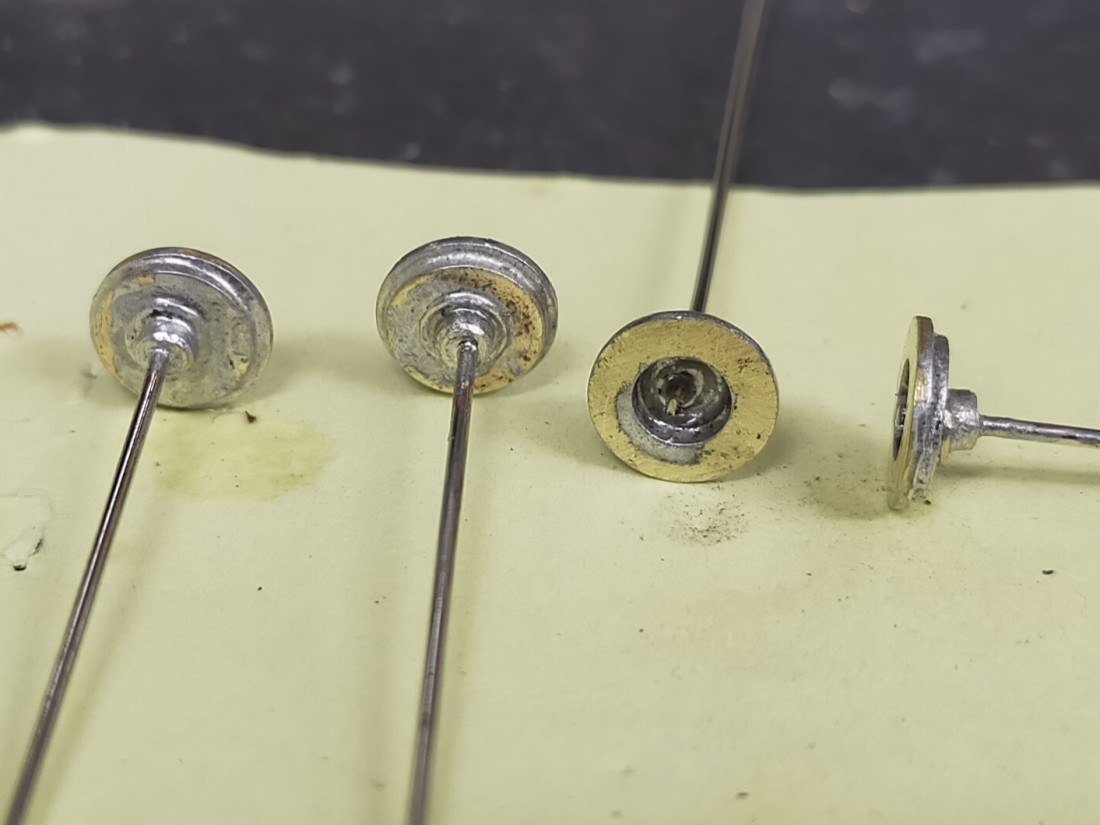

On the left we have brass washers of 7mm outside diameter. On the right we have 3BA brass washers of about 5mm outside diameter. In the centre we have some 4mm scale brass axle bearings. First job is to clean them up and solder a small washer to a large washer. But how to ensure that the centres are aligned? Like this..

The tool being held vertically is from a soldering kit. What is important is that it is tapered. The card is in place to prevent the heat from the soldering iron disappearing into the pliers. Apply liquid flux and solder to get this..

Last edit: by col.stephens

Last edit: by col.stephens

Posted

Full Member

Posted

Full Member

I'm minded to bend the wire to produce some a 'swan-necked' type lamp standards, or even a typical yard lamp with a loop surrounding the lamp housing. Another lamp will be of the bracket type over a door.

Next I'll solder up two pieces of tube to make each post,

Terry

Posted

Site staff

Ed

Posted

Full Member

Neat soldering - is the bearing a normal top-hat type ?

'Petermac

Posted

Full Member

Hello Peter. Yes. These are Alan Gibson 4mm scale top-hat bearings. They are from a packet which I have had in store for some time.Petermac said

I'm watching carefully.

Neat soldering - is the bearing a normal top-hat type ?

From “Post #289,609”, 5th February 2024, 10:42 AM

Terry

Posted

Full Member

Thanks Ed. Very kind of you.Ed said

Terry

Posted

Full Member

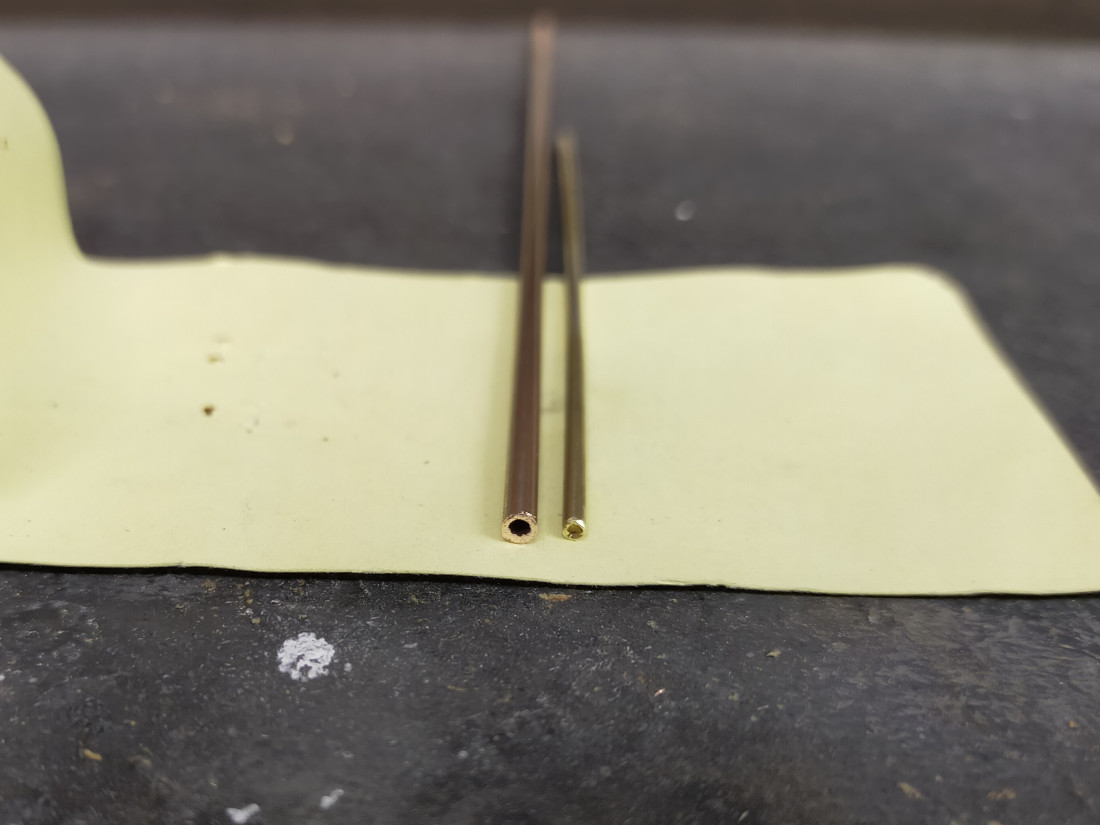

I found a few short offcuts of tube to be used to make the post. One is brass tube of the type used for wire in tube control of turnouts and signals, and the other is a slightly larger diameter copper tube. Any tube will do as long as one will slide neatly inside the other.

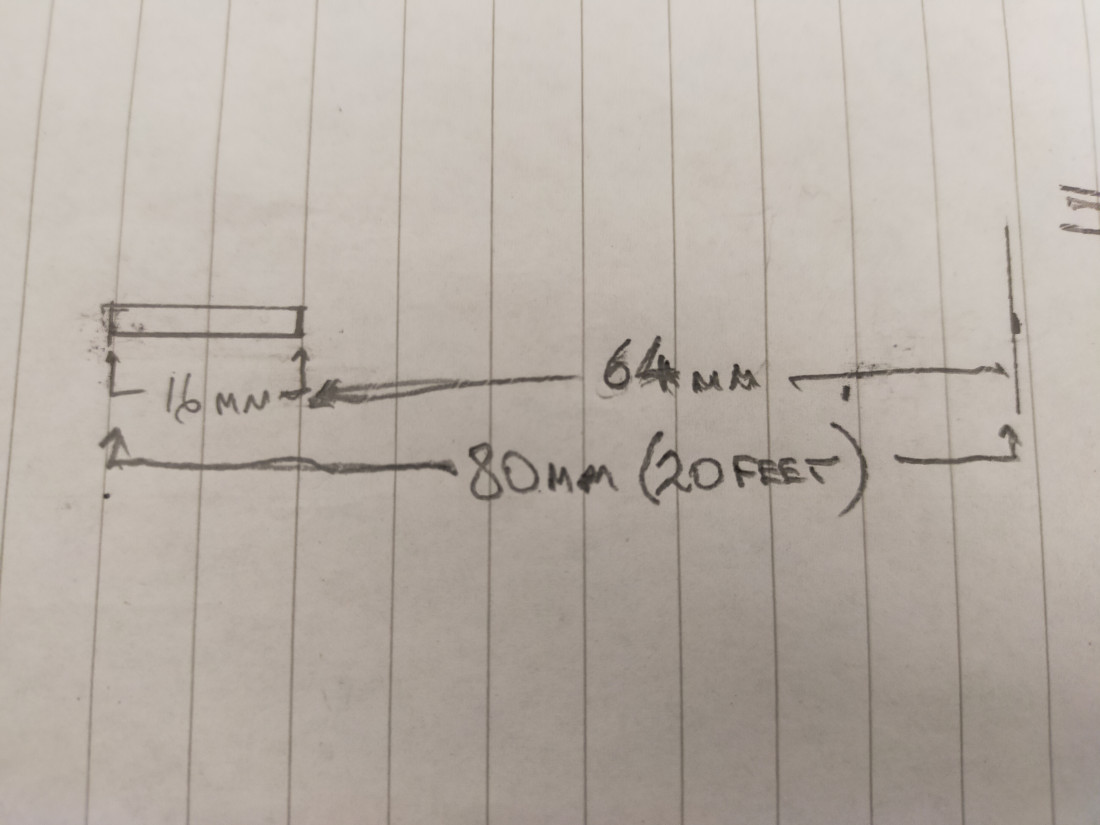

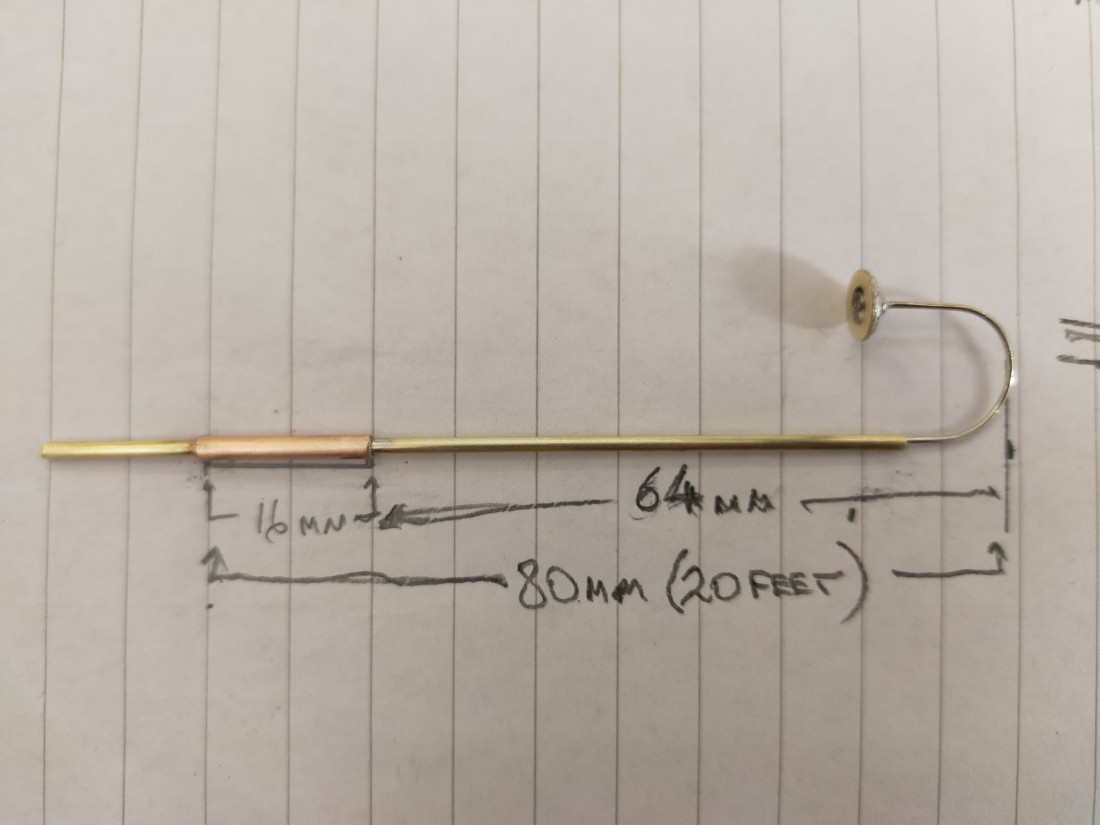

Assuming the lampposts are about 20ft high, a scale drawing would be useful. Obviously, you can adjust the drawing to your preferred height.

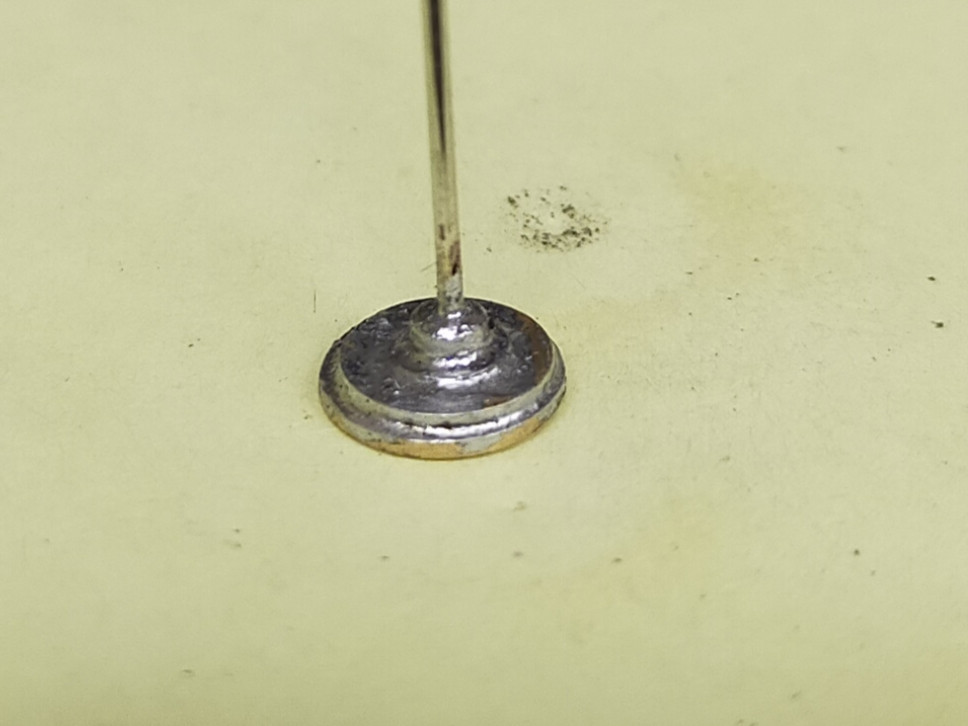

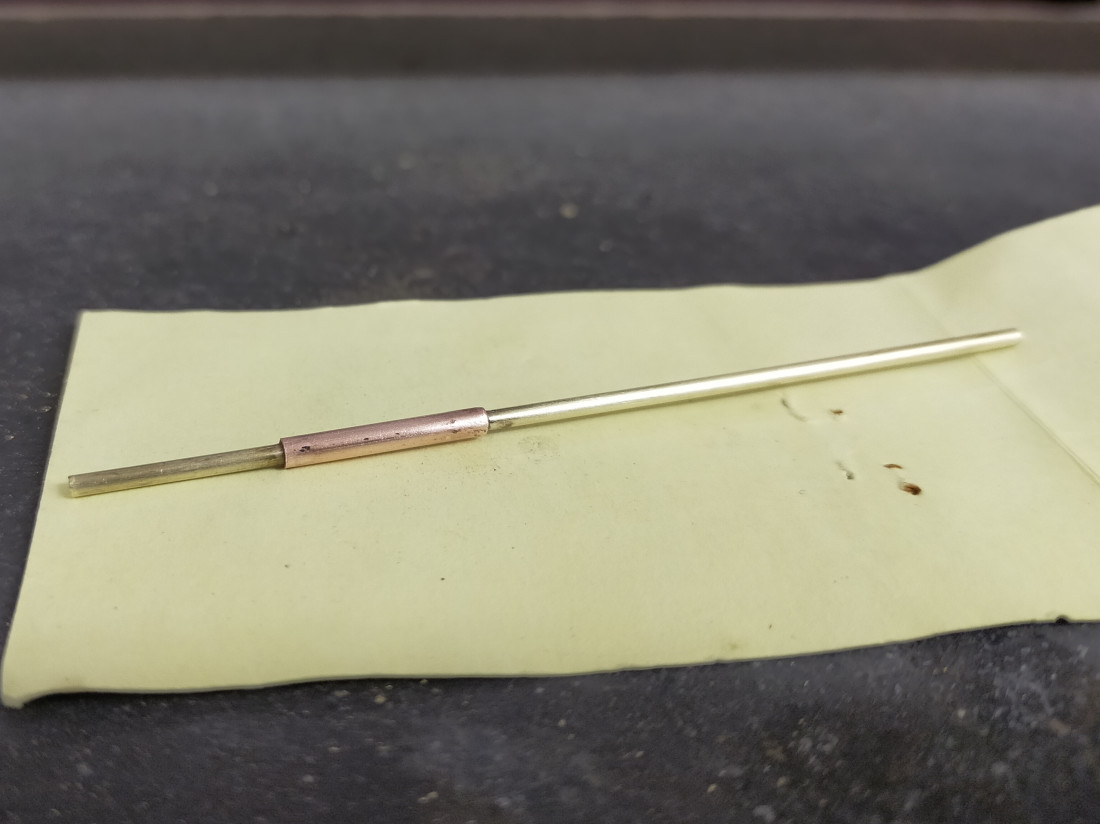

Cut a 16mm length from the larger diameter tube. This will form the lower, and wider, part of the post. Once cleaned up, slide it over the narrower tube and establish its position using the drawing. Also decide on the position of the top of the post, represented by the narrower tube. Solder the tubes together at the top of the wider tube. The narrower tube, protruding from below the wider tube, is to allow the lamppost to be mounted through a hole in the baseboard.

Posted

Full Member

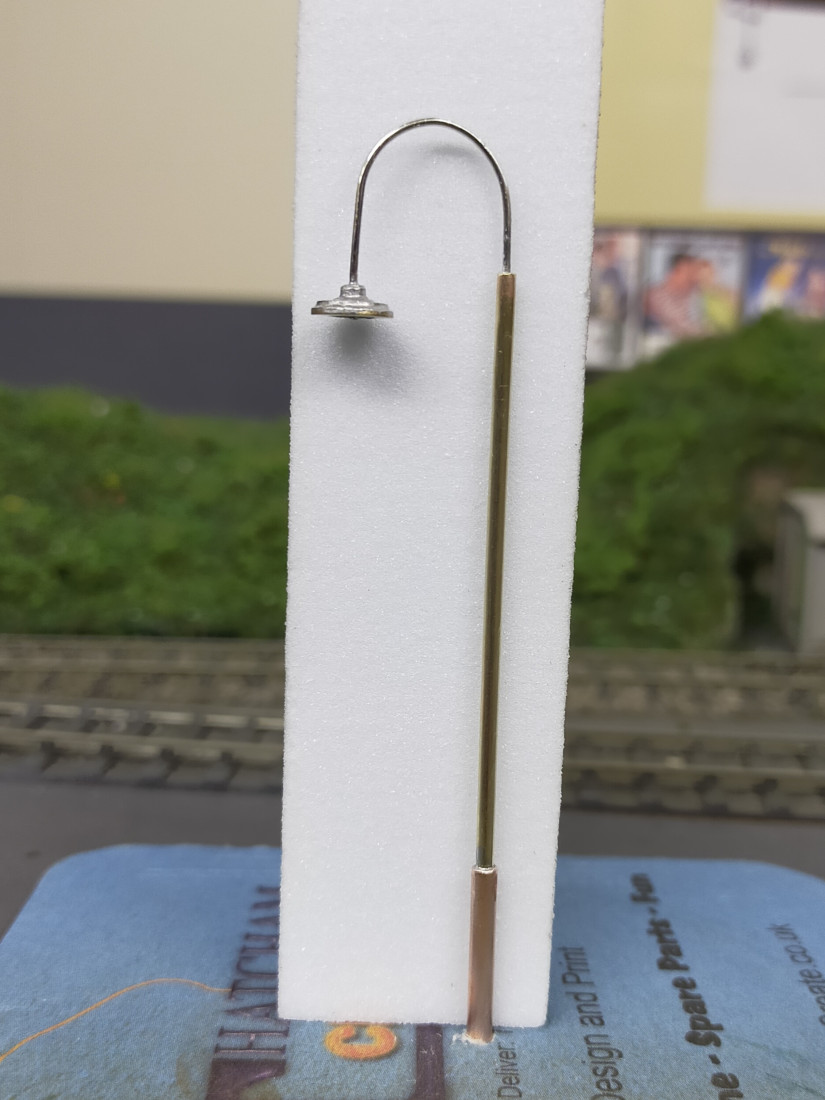

Push the wire into the top of the post. Lay it on the drawing and adjust to the correct height..

Solder the wire to the top of the post. You should have something akin to this, ready for the paint shop..

Terry

Posted

1 guest and 0 members have just viewed this.