Whatsthename new OO steam DC terminus

Posted

Site staff

Layout blog

I find nothing wrong with hand driven Roger, it's less for me to b#@@£r up ! Even my points are hand driven at the moment. I find what you guys do quite fascinating and think I really SHOULD start mechanising ( electricalising ??) Some of it but at the moment I'm finding no time to even RUN things let alone work on anything. the semaphore signal motorizing sounds interesting :hmm I'm looking forward to seeing what you are experimenting with ! :thumbsCheers

Matt

Wasnie me, a big boy did it and ran away

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

Posted

Full Member

Just catching up on the build. I was scratching my head on why you had so many switches for the transfer table, then remembered you were using DC, not DCC. What are you using antifriction-wise for the table? When I did one of these I used UHMW polyurethane strips (or was it polypropylene? Same material used in artificial joints). Like you I didn't bother with a mechanism. If I had it would have been a linear motor with adjustable stepper control.

Looking at your plan I was struck by all that acreage in the corner. 2 x 2 feet. More than enough for a turntable.

One advantage of using a cutting disc for the rails is that it automatically generates an insulting gap, removing the need for insulating joints. I have a right-angle attachment for the Dremel, gives an almost 90° cut and the track, much more controllable as the Dremel is at 90° to the track. (I always wear goggles, I had a Xuron cutter explode with fragments embedded in the lens a couple of years ago, and cutting discs shatter on a regular basis unless it's one of the heavy duty reinforced ones).

Following with interest. Old school DC and Peco HO/OO track. Any reason why DC and not DCC?

Nigel

©Nigel C. Phillips

Posted

Full Member

have you any suggestions for a linear stepper motor system which a non-expert could set up and most importantly control. I can find any number of linear drive / motor combinations to buy but it's the control aspect I'm unsure I can deliver.

Colin

Posted

Full Member

Hi Roger,

Thx for getting back so promptly. I've been discussing this with a friend who is a dab hand at things electro-mechanical and he's been suggesting a stepper motor driven device. That got me wondering what you might have done, given your aptitude in this area.

I'll be putting up some more posts shortly as I'm doing an early trial run assembling the Traverser in situ, now that the main framework is in place.

I hope you're finding some time to progress things at your end.

Regards,

Colin

Hi Colin,

My present traverser has a fair amount of friction from wood sliding over wood though both surfaces are polished, it was intentional to hold things in position. However my experience of steppers is that any undue friction results in missed steps or even complete failure. Missed steps are disastrous if positioning is only done by counting steps.

I think I would use the same drive method as at Riccarton that being geared servo motors driving a cord system but endless as there is no need of a counterweight. Feedback was by small magnets secured under each rail entry and a linear hall device under the fixed track, this gives position counting as well as absolute alignment but as I said before quite a lot of microprocessor code to do in particular around the fine positioning loop using the linear hall signal. Of course the advantage is positioning is independent of friction and there is plenty of torque (depending on motors) available to overcome it.

Possibly optical feedback may work for those who prefer it but I always find ambient light gets in the way of reliability.

Of course a chunky stepper and minimising friction may be a way simpler means of achieving a result ;-)

Regards

Roger

Last edit: by spurno

Last edit: by spurno

Roger OO DC Steam

Posted

Full Member

I find nothing wrong with hand driven Roger, it's less for me to b#@@£r up ! Even my points are hand driven at the moment. I find what you guys do quite fascinating and think I really SHOULD start mechanising ( electricalising ??) Some of it but at the moment I'm finding no time to even RUN things let alone work on anything. the semaphore signal motorizing sounds interesting :hmm I'm looking forward to seeing what you are experimenting with ! :thumbs

Cheers

Matt

Hi Matt,

Well it was nice to have a rest from complexity and I wanted to get the layout operational asap. One change I did make however was to change from solenoid to servo operated points and I am very pleased I did even though I was slowed down by some teething problems (my rubbish software again). This is now forming the basis of experimenting with operating semaphore signals, so far my experiment has been limited to the mechanical side as shown in the pictures, I chose the old diecast Hornby (typically Dublo era I believe) signals as these are much more robust than the plastic things I have seen & tried to use in the past, they are quite easily obtainable via *bay auctions in various states of decay but simple to rebuild & paint. The only disadvantage to soldering the operating wire as shown is having to unsolder it to remove the signal from the baseboard although possibly unscrewing the servo arm in situ under the baseboard is another option.

I am fairly confident I can use my existing point control software to operate the signals although some work will be required to interlock them with the points. I believe the commercial Megapoints controller could probably operate them as well but perhaps not do the interlocking (I am no expert on it's features).

Regards

Roger

Roger OO DC Steam

Posted

Full Member

Hi Roger,

Just catching up on the build. I was scratching my head on why you had so many switches for the transfer table, then remembered you were using DC, not DCC. What are you using antifriction-wise for the table? When I did one of these I used UHMW polyurethane strips (or was it polypropylene? Same material used in artificial joints). Like you I didn't bother with a mechanism. If I had it would have been a linear motor with adjustable stepper control.

Looking at your plan I was struck by all that acreage in the corner. 2 x 2 feet. More than enough for a turntable.

One advantage of using a cutting disc for the rails is that it automatically generates an insulting gap, removing the need for insulating joints. I have a right-angle attachment for the Dremel, gives an almost 90° cut and the track, much more controllable as the Dremel is at 90° to the track. (I always wear goggles, I had a Xuron cutter explode with fragments embedded in the lens a couple of years ago, and cutting discs shatter on a regular basis unless it's one of the heavy duty reinforced ones).

Following with interest. Old school DC and Peco HO/OO track. Any reason why DC and not DCC?

Nigel

Hi Nigel,

Thank you for your interest, my story of DCC/DC is a very long one as I actually ran a predecessor to DCC of my own design for many years that did not require loco decoders :shock: however the technology at the time (including the available micro-controllers in the mid 1990's) was not really up to it. Anyway I like DC for the simplicity (to me) of automation when I have used it in the past but mostly because now I am moving into OO with largely 2nd hand stock I don't have to face the additional cost of a decoder every time I buy a loco.

The traverser apart from two pairs of ball bearing drawer slides uses polished wood surfaces for another four supports as I did not want any warping, but I like your idea of plastic strips to further reduce friction if I was to motorise it.

I deliberately chose not to have a turntable and operate the line with tanks, also the available corner is a little inaccessible, instead it's siding will be into an industrial/creamery area as yet undecided. I think I would have planned the whole layout differently if it was to have a turntable preferring it to be near the front of the baseboard.

I have been lucky with cutting disks, over the years I have broken one or two but that's out of some dozen or more used, I don't like the sound of those cutters exploding :roll: nasty, I have never used them as I assumed one has to file of the burrs on the rail afterwards.

Regards

Roger

Roger OO DC Steam

Posted

Full Member

I have on occasion in the past built large semi automated layouts and wondered if I was just using the railway as an excuse to write interesting software and devise interesting electronic circuitry having a lifetime interest in both but I do try to keep a lid on it and for that reason this my first OO layout is almost entirely manually controlled the only unrailway like bits being the servo-controller for the points. Anyway here are a few pics of progress as some buildings have been built, stock increased and ballasting completed since my last progress post. The main area remaining incomplete being the station buildings and platform canopies (plus some people & fencing etc).

Roger OO DC Steam

Posted

Full Member

Interesting. I keep the DC control side separate from the DCC (used only for locomotive control). All of my current locomotive stock is previously used (and in a few cases abused), most of them came with dinosaur motors with horrifying initial current draw. Throwing in a new motor/gearbox and a basic DCC decoder still keeps costs to a fraction of a new one. I quite like the sound of those old Lima ringfield motors with the gears whirring around .

The UHMW plastic is very slippery. If you retrofit it doesn't glue well being almost chemically inert. I had to use CA and countersunk screws. In retrospect some sliding drawer glides or embedded round rollers would have been a lot better (and a lot cheaper than a decent linear drive/motor and control unit). Then again, a tad of friction keeps it located. One advantage of DCC is that you can have multiple storage tracks in a ladder with only one entrance/exit and zero switches. Takes the fun out of it though.

Nigel

©Nigel C. Phillips

Posted

Full Member

Hi Roger,

One advantage of DCC is that you can have multiple storage tracks in a ladder with only one entrance/exit and zero switches. Takes the fun out of it though.

Nigel

I like wires :) I was told this all started when I was very young and disappeared under the floorboards along with the family cat when the house was being rewired

Roger

Last edit: by fourtytwo

Last edit: by fourtytwo

Roger OO DC Steam

Posted

Site staff

Got me thinking Thanks :cheers

Chheers

Matt

Wasnie me, a big boy did it and ran away

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

Posted

Full Member

Interesting reading about your working semaphores and I'd echo your comments about the lack of strenght in the, otherwise excellent, plastic offerings available.

I have the Megapoints system operating some of my points and, whilst I've had a few problems centering everything, it seems an excellent system. I'm planning to attempt some brass MSE kits using Megapoints and servos to operate them. I have no idea about any interlocking possibilities but Dave Fenton - Mr. Megapoints himself - is extremely helpful so I'd strongly advise contacting him to ask.

Initially, the system looks expensive but when you divide that cost by the number of servos it can control, it looks far more reasonable.

'Petermac

Posted

Full Member

Hi Peter,I have no idea about any interlocking possibilities but Dave Fenton - Mr. Megapoints himself - is extremely helpful so I'd strongly advise contacting him to ask.

Thank you so much for your kind comments though I know your kidding me about your models having seen photo's!

We have our wires slightly crossed about the Megapoints I was only suggesting it for people who did not wish to write there own software, where as I make my own blunders

Roger

Last edit: by fourtytwo

Last edit: by fourtytwo

Roger OO DC Steam

Posted

Full Member

We are at other ends of the observable Universe in terms of competence regarding most matters electrical. So, I'm suitably impressed and dissuaded in equal measure now I've seen your traverser control at Riccarton.

My skilled friend likes a challenge and is happily playing around with various ideas, I'll see what he comes up with. It will not be long before I can lay some track on and approaching the traverser, that will give me a better handle on the issues involved. "Handomatic", remains an entirely feasible option in any case.

Regards,

Colin

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

I too have gone a similar route being limited for space and have sometimes pondered if I have squeezed in too much track work but being more interested in station operations than ‘running around’ I will live with it.

The controllers you refer too I guess are from the circuit by Roger Amos which I also use and after acquiring a well known manufacturers controller from eBay for comparison I was somewhat disappointed and quickly resold it.

On dismantling a larger layout due to a house move I sold all my point motors and now am a convert to the Megapoints system for points and will be using it to control my signals when I get round to it.

I have tested one with a servo just to see how the various ‘bounce’ and ‘signal pull off’ features work and I am hooked.

I am currently making a turntable for my shed and now being unable to access proper engineering equipment I am having to design it for ‘table top’ engineering.

I am using the Dapol/ Airfix kit and introducing bearings in the table, electrical pick ups for the rails along with under baseboard indexing system (servo operated) and ‘floppy’ drive connection to turntable using readily available materials and bits and pieces that I have.

Looking forward to your layouts progress, incidentally what coupling/uncoupling system are you planning to use?

Regards

Mr Tee

Posted

Full Member

Actually a vertical traverser is much more difficult IMOP because of the variable load and vertical alignment being affected by bouncy floorboards all of which has to be compensated for. At least in a horizontal system the load only affects the friction. I am sure your friend will enjoy coming up with a system, in the meantime I can recommend the "handomatic" system ;-)

Regards

Last edit: by fourtytwo

Last edit: by fourtytwo

Roger OO DC Steam

Posted

Full Member

EDIT Ahh heaves big sigh of relief the Bachmann parts arrived today and fitted almost perfectly just one slightly oversized hole on an axle spacer easily fixed, so hopefully there will be time tomorrow for more testing & restoration of the body adding another loco to the roster. I have yet to decide what lubricant to use on the wheels as I have heard mineral oil is a no-no, someone mentioned model helicopter gearbox grease that sounds interesting :)

EDIT EDIT Decided this morning to try pencil lead, used a soft 7B pencil and seems to work ok as a lubricant w/o interfering with pickup, I am sure there is a lot of clay in it that is an insulator too…… may not be the perfect solution but at least it should not damage the plastic wheel spacers.

Meanwhile reams of tables etc have been produced as part of the re-signalling project to try and ensure as much of the already installed wiring remains the same when the existing points controller is extended to encompass the forthcoming semaphore signals.

I am somewhat regretting the circuit boards are screwed to and wired under the baseboards as although that makes moving the layout (should it become necessary) easy it makes major modifications like this a back breaking nightmare!

EDIT have completed the hardware modifications necessary to add semaphore signals to the existing points controller BUT the CH340 USB to serial controller that has always worked before has chosen this time to randomly lock-up making communications to it impossible Grrrr

EDIT EDIT Sunday found the answer to that one as well…… if the transmit line to the CH340 is held at 0V creating a break condition it refuses to receive anything….. Restoring the transmit line to the normal high level and woohu the receiver works! Needless to say bug introduced by me when changing chunks of point controller code to increase capacity.

Last edit: by fourtytwo

Last edit: by fourtytwo

Roger OO DC Steam

Posted

Full Member

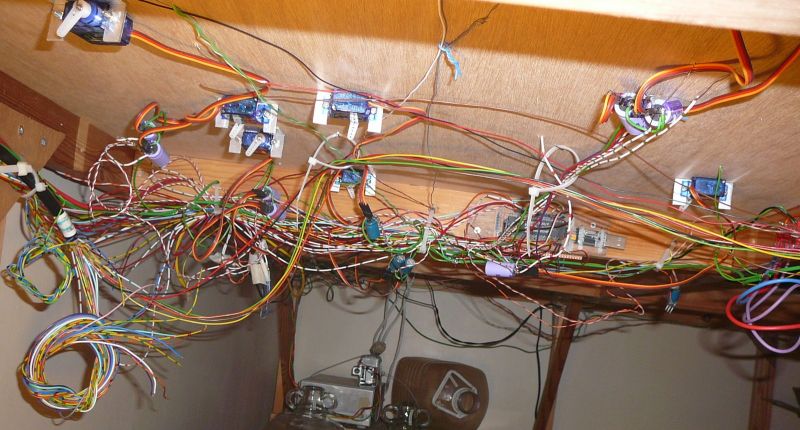

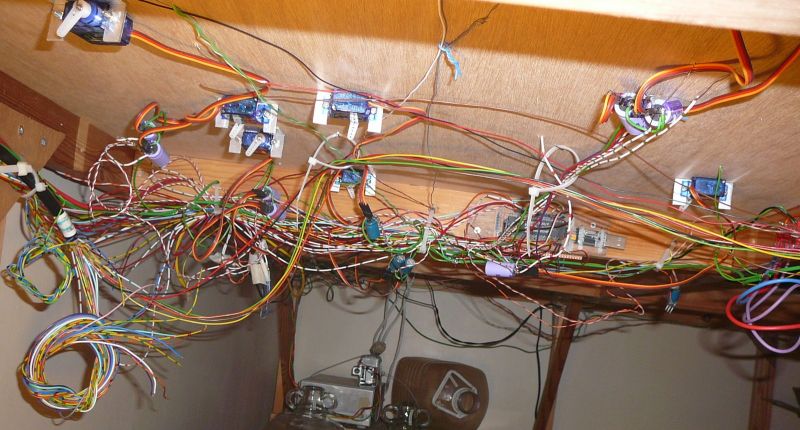

The reason for the changes is to extend the number of inputs & outputs available to accommodate the forthcoming semaphore signalling. I have seen comments about other peoples under baseboard wiring, so here is my mess. I actually find semi point to point easier to trace than everything neatly laced up (that's my excuse and I am sticking to it) :roll:

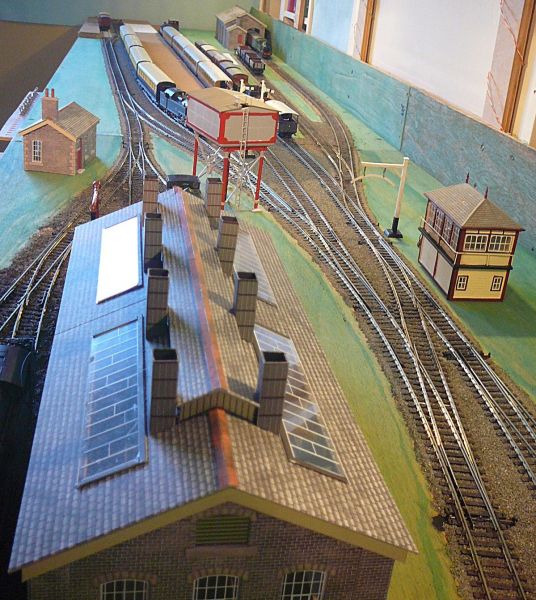

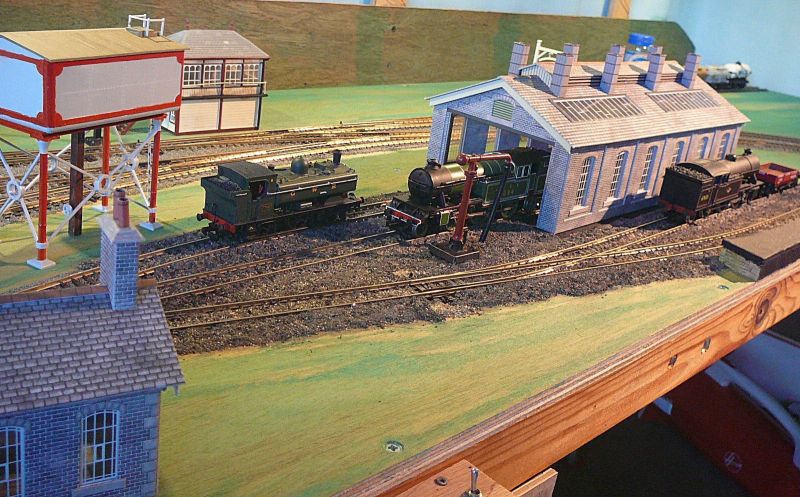

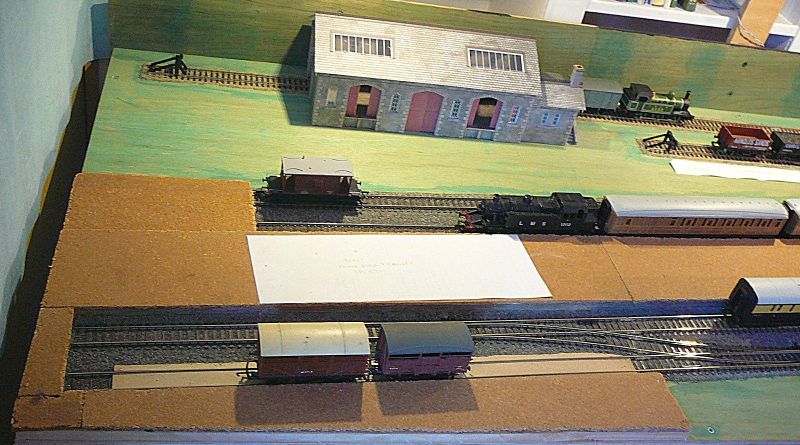

Now for the topside…….

Coaling is 262T BR V1, over the ashpit is LNER V3 262T, nearer shed road is BR Fairburn 264T and behind it is BR Fowler 264T.

Having arrived with a passenger is LMS Ivatt 262T & shunting the cattle is LNER J72 060T, the latters cab roof seems to be arranged for additional driver cooling that I have only just noticed :)

Finally we have a GWR 57xx Pannier at the head of a recently arrived mixed goods.

A birds eye view of the station

Seasons greetings everybody and may Santa grant all your wishes ;-)

Last edit: by fourtytwo

Last edit: by fourtytwo

Roger OO DC Steam

Posted

Full Member

I may have spotted the cause of that interesting nest of wiring in the form of the discarded empty demijohns Colin Roger!

Scary stuff:thud

Bill

:cheers

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

I plead "Not Guilty m'lud". "I was nowhere near the scene of the crime at the time"

I may have spotted the cause of that interesting nest of wiring in the form of the discarded empty demijohns Colin!

Scary stuff:thud

Bill

:cheers

In fact I've been getting by quite nicely in a different hemisphere :roll:

Posted

Full Member

I won't bother with excuses. Just one of those senior moments, possibly aided by RLW!

Happy Christmas,

Bill

:cheers

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

1 guest and 0 members have just viewed this.