Peco Electrofrog L/ H point

Posted

Full Member

Appears to be dead

Hi Max, Petermac, Ed, and all of YMRC. For me this is “ Deja Vu “ . Back in February 2016 I had the same problem.It did get sorted and up until now I have used the same method of wiring without any trouble. Last night, after a very tiring day. I oiked up the set of “ points “ for want of a better name? Incidently I have heard the term “ splitting the points “ I didn’t do it myself. And at that time one of the wires became loose. Now I have replaced that wire, and later today I will reassemble the whole kit and caboodle and report back. I did learn the techniques of a YouTube Modeller ,good or bad? Who was fussy about soldered joints corroding, to save that happening he scrubs the joint with clean water and then dries it. I have tried this idea, and the wires stayed put! Best wishes Kevin

Last edit: by Passed Driver

Last edit: by Passed Driver

Staying on the thread Kevin.

Posted

Full Member

Posted

Full Member

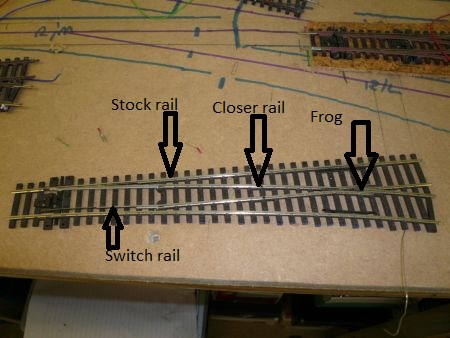

I wonder if this might help - something I did for my own use originally when trying to explain turnout or point parts.

The "Switch" rails are joined to the Closer rails by the "hinge". The Switch rails are normally referred to by modellers (incorrectly) as the blades.

Notwithstanding that, Kevin it would be good to know what bits of your turnout/point are live and what parts are dead. The train can only go straight on or around the curve so perhaps you should indicate

(1) whether the problem occurs for trains going straight on or around the curve or both

(2) whether the loco stops when coming from the left in the above photo (toe end) or the right (frog/crossing end)

(3) whether you can prove that the attached wire (seen bottom right) is actually properly connected to the crossing/frog i.e. there is electrical continuity between these two.

Finally (4) The drawings of the frog polarity switch posted earlier are, of course, right so can you confirm that you have wired up your point/turnout exactly as drawn.

I am sure that the guys on here can sort you out once the problem is understood. Hopefully the above will lead us down that path.

Best wishes

Barry

Shed dweller, Softie Southerner and Meglomaniac

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Site staff

Ed

Posted

Full Member

Last edit: by Passed Driver

Last edit: by Passed Driver

Staying on the thread Kevin.

Posted

Full Member

Nigel

©Nigel C. Phillips

Posted

Full Member

Staying on the thread Kevin.

Posted

Site staff

to join two pieces of wire rod together to get correct throw length

of course, this can be hidden under scenery.

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

That's a good idea Ron. :thumbs

Terry

Posted

Site staff

Cheers

Matt

Wasnie me, a big boy did it and ran away

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

Posted

Site staff

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Site staff

but with the number of slide switches along the from to the baseboard, even my mate ( who was a signalman back in the UK ) got confused so I electrified many of them controlled from a panel.

But many still are manual like this one

the tubing and connector is cut into the 3mm cork & hidden under the grassed area tween slide switch & track.

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Araldite is wonderful stuff until you hav to remove it!!

I have had success with Nitromors - a proprietary paint stripper than you can get from hardward stores/DIY sheds - but ITS NASTY STUFF so take ALL of the precautions on the tin and BE CAREFUL.

Someone told me once that nail varnish remover also works but I cannot vouch for its success. These sort of chemical-based products have gone through so many Health & Safety changes over the recent years that what may have worked a decade ago may not work now.

Hope that helps

Barry

Shed dweller, Softie Southerner and Meglomaniac

Posted

Full Member

Staying on the thread Kevin.

1 guest and 0 members have just viewed this.