Gladiator LNER/BR J6

Posted

Full Member

I had anticipated that one of them may not fit very well and might leave a gap that would in fairness be hidden by the coal but I was pleasantly surprised when after a little tweaking with pliers and a rub of some abrasive paper it went into place as it should. Just the details and coal rails to add now.

I am not sure why but I chose to use shiny sinks to clean it up after I finished instead of my usual Bar Keepers Friend and it turned all the solder black making it look to be worse than it is.

Regards Rob

Posted

Legacy Member

reg

Posted

Full Member

Regards Rob

Posted

Full Member

While struggling with the instructions I hadn't read the text when fitting the lifting eyes I just followed the drawing which unfortunately showed the wrong type of backing plate. Reading through the text late last week I saw my error and by coincidence David Hill of Gladiator pointed it out the day after on the Guild forum.

My customer had seen the post and said it didn't matter if they didn't show too much but it was only a few minutes of a job with the microflame and a scalpel to take them off and swap them for the right ones.

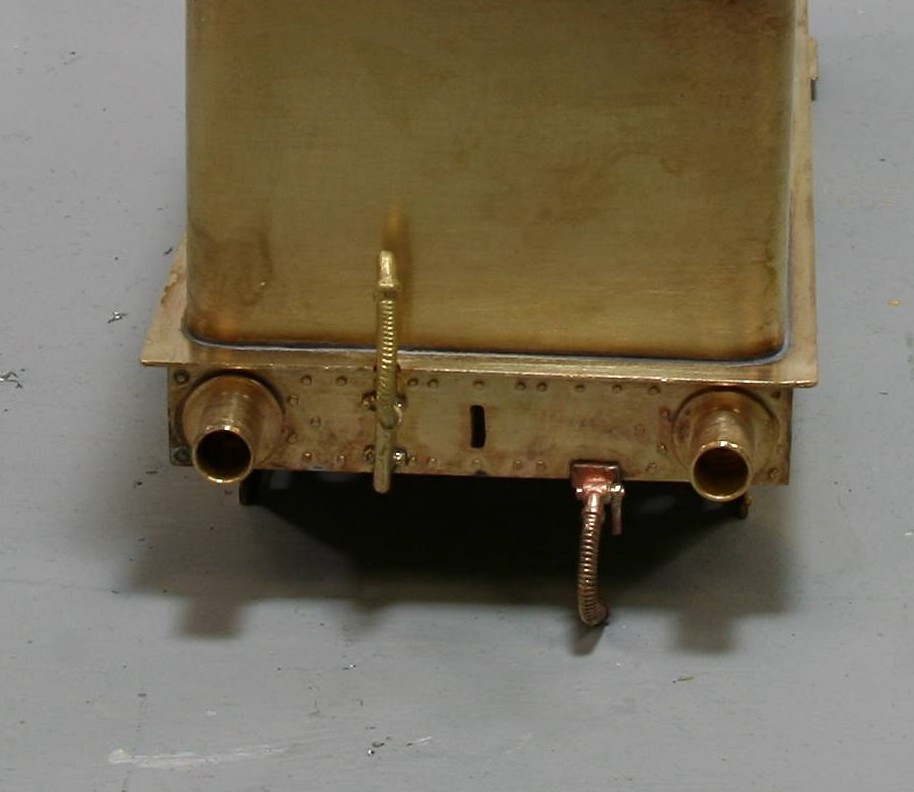

Next I added the vacuum and steam heat pipes to the rear of the tender.

Then I started on the front.

The brake standard was one that I had in my spares box that was left over from the B16 build. The other levers are bent wire and scrap etch.

The bucket is one of Jim McGeown's castings that I had sat on my desk for a long time after I had made a bit of a mess of trying to hollow it out.

I took it back into the workshop to see if I could do anything with it after being informed that the hole in the left hand side was for a bucket. I then remembered the collets that I had made for drilling the valve guide castings on the Streamlined Duchess and used one of them to tidy up the inside of the bucket top using a dental burr and lastly soldered a handle on from scrap etch.

Regards Rob

Posted

Full Member

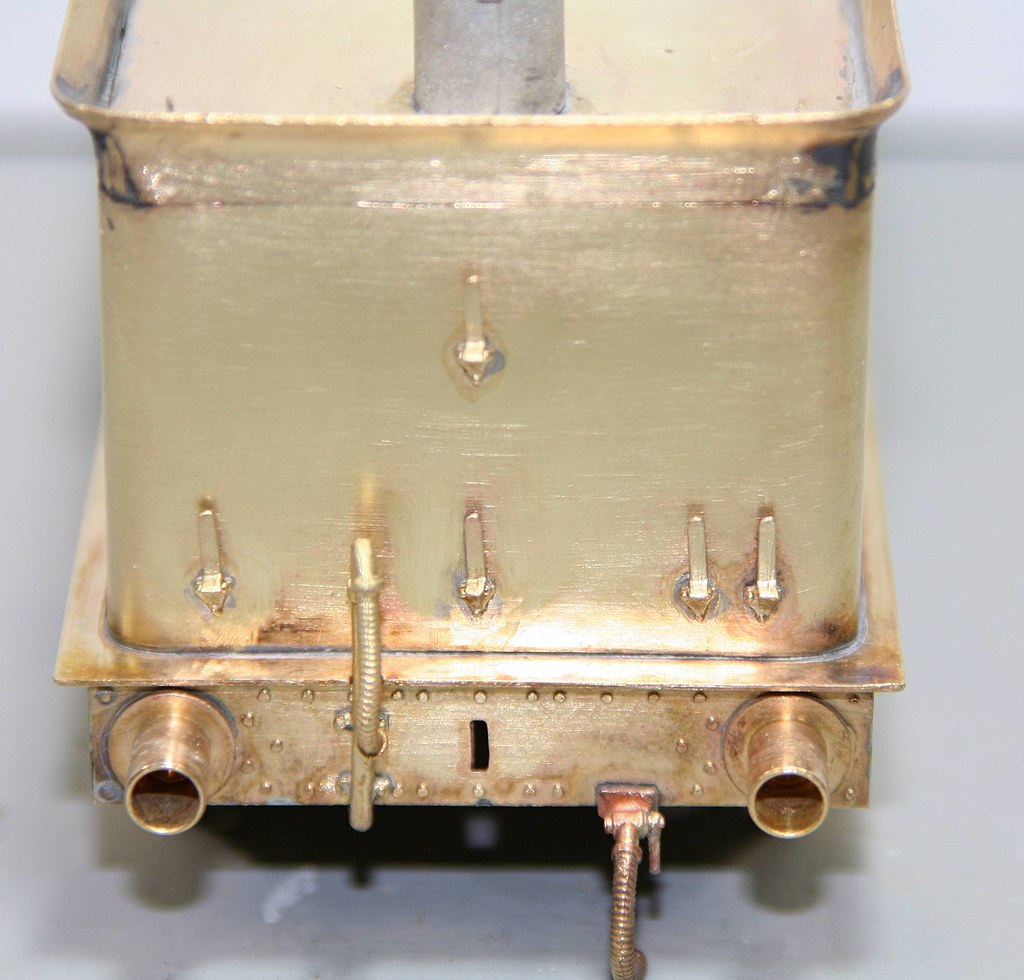

I have also fitted one inside the side sheet at the front of the tender but alas the camera decided to focus on the nearside so the added lamp iron came out so blurred you couldn't see it.

I will try again when I next take photos.

I did manage to add the tank filler though so another detail bites the dust.

Coal rails next I think.

Regards Rob

Posted

Full Member

Great job. Again!

Michael

Posted

Full Member

Although I really appreciate the comment, I too had to start from scratch learning to solder etc. as I went along.

I was/am helped by the fact that my pleasure comes from the making rather than the running of model railways. I have built a lot of models in the last 10 years too which helps to perfect techniques.

Because we stayed in Wakefield this weekend it gave me an extra evening at the bench - usually I am worn out by the time we get to Bishop Auckland and rarely do anything once I arrive on Friday evening.

As luck would have it I was able to finish work early too so I had around 5 hours at the bench which saw off the remaining upper works details.

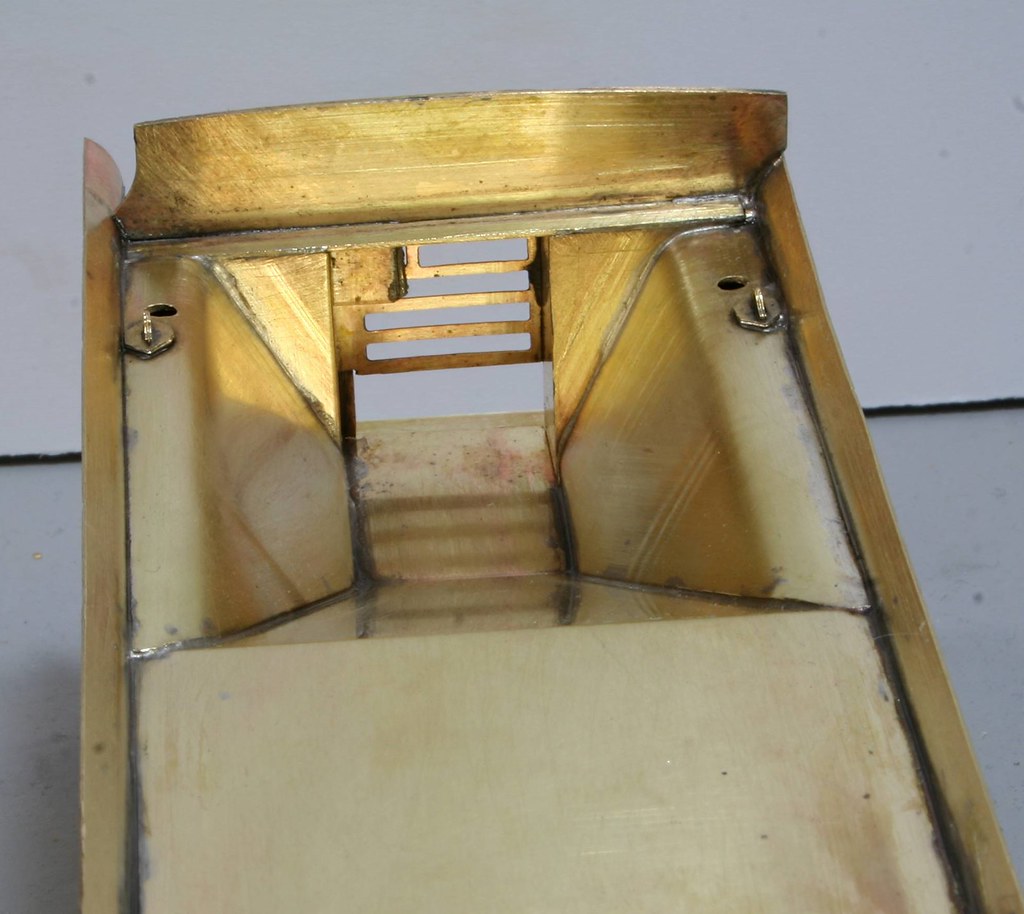

The coal rails were too long and I had to split them at the rear of the tender. I think that this is a result of the cut out in the tender flare for the hand grip which is a feature of this type of tender.

I followed David Hill's example and soldered half round beading over the coal rails and what an improvement it's made.

I also put half round beading in one the inside of the front hand grip sections to make it a round profile. and you can see the additional lamp bracket too which wouldn't focus on my last photo session.

I also got around not fitting a nut to secure the front of the tender top by tapping a piece of tube and soldering it in when the nut should be.

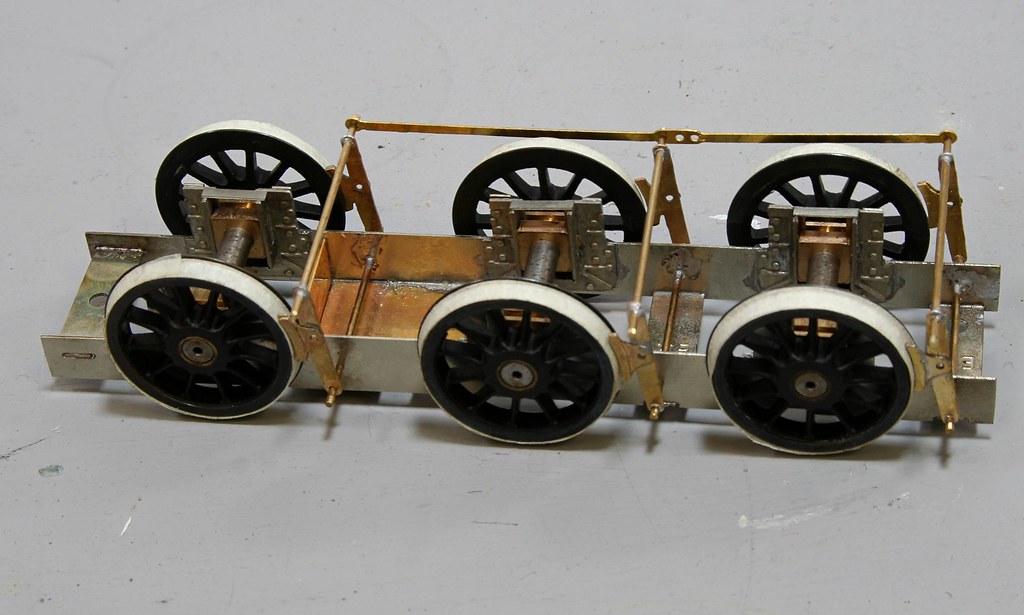

This just leaves me with the chassis which I have made a start on.

Regards Rob

Posted

Full Member

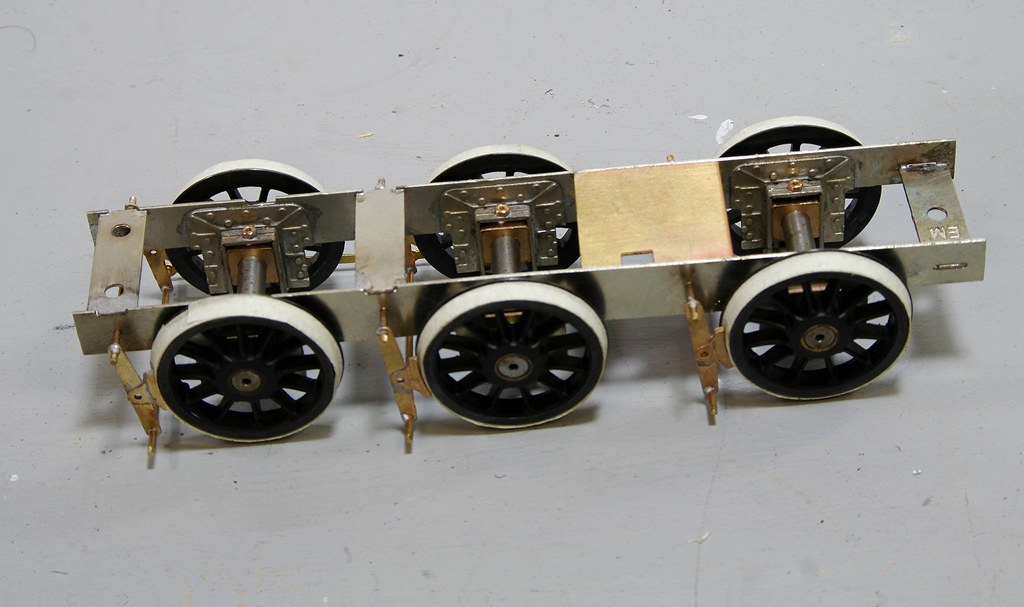

You will note that I have added an extra frame spacer. I did this because I am using the tender for pick ups and wanted to ensure that there was no flexing which might affect them - The brass spacer was a scaled up P4 spacer from the spares box which I cut down to fit.

Back onto the loco next.

Regards Rob

Posted

Full Member

Some this was my own fault because it's quite thick nickel silver and like David found out when he built one recently, you need to file a lot out of either side of the fold lines to allow the valances to sit vertical. I had attempted to fold up one side some time ago which needs a bit of brute strength but then found that it wouldn't come to 90 degrees.

The first job was to straighten the side already bent enough to allow me to file out the fold line. I did this by annealing with the microflame and then using the vice to squash the etch back almost flat. Once I had filed the fold lines, I bent it as far as I could with one of the sides off a set of bending bars and then used a rubber mallet to bash it to the final 90 degree fold while the middle section was firmly gripped in a second set of bending bars to ensure that it stayed flat.

Hopefully I will get the footplate shaped and soldered on tonight so I will take photos after that.

Regards Rob

1 guest and 0 members have just viewed this.