Gladiator B16/1 A North Eastern Workhorse

Posted

Full Member

The completion of the build of a 7mm scale B16/1

Well, that wasn't quite what I meant Allan. If that is so though, then who is the nave? :hmmJohn

John

Posted

Full Member

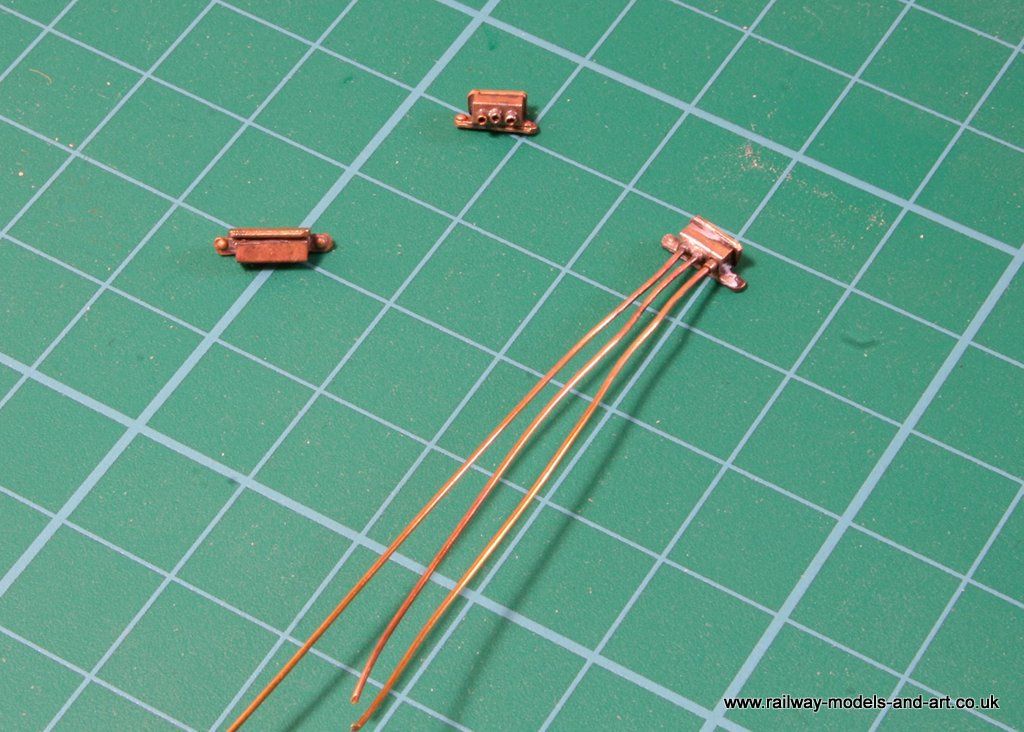

Although I have some castings they are too long and wouldn't cut down very well so I decided to have a bash at making some from scratch.

I measured the length of three together and marked it off on a length of square bar and then marked a line 1mm from the top, along what will be the front edge. Next I filed the marked section down to the line at the front while maintaining the full height at the back. - To give me a sloping top.

A strip of scrap etch to form a lid and another length with two rivets punched in either end forms the mounting bracket.

Before cutting each individual oil box off the bar I drilled holes for the pipes in the bottom and then added some 08mm OD tube and length of fine brass beading wire to represent the oil pipes. Three down three more to make for the other side but at least two of them don't need the tube/pipes fitted because they sit on the splasher top.

Regards Rob

Posted

Full Member

John

John

Posted

Full Member

I am using this build to get used to making parts using my new mini pillar drill to do things that I wouldn't have attempted using the Dremel or a pin vice.

Regards Rob

Posted

Full Member

I imagine you would need a high precision pillar drill.

John

John

Posted

Full Member

Like you I bought a stand for the Dremel but sadly it's far too inaccurate for the sort of stuff that we do modelling wise.

Last Christmas my good lady bought me a Proxxon mini pillar drill which is superb for drilling accurate holes. I invested in a compound table for it which allows me to minutely adjust the position of the work piece. That added to the overall accuracy of the drill press itself make it a winner for me.

Regards Rob

Posted

Full Member

John

John

Posted

Full Member

I used to use my full sized one where needed and hand drill the rest with a pin vice.

My full sized one is fine with bigger drills but has too much play for use with the small drill bit's that are needed for modelling. Admittedly mine is one of the cheapish DIY store offerings which was around £80 when I bought it a few years ago and I didn't buy it with modelling in mind (bought before I returned to modelling).

Regards Rob

Posted

Full Member

John

John

Posted

Full Member

I rather suspect that mine will do the same and it's not worth trying to sell them as new ones are so cheap and they are not easy to transport.

Regards Rob

Posted

Legacy Member

I bought a pillar drill once, drilled two holes with it then 2 years later gave it away to the postman who really didn't want it either.

Allan.

Posted

Full Member

Regards Rob

Posted

Full Member

John

John

Posted

Legacy Member

What we could all do with are council funded municipal pillar drills in every town.

I'll get on it right now.

Allan

Posted

Full Member

John

John

Posted

Legacy Member

Allan

Posted

Site staff

Is that BOGOF Alan quest: quest: quest: quest:Visit a pillar drill near you and get a two holes for the price of one introductory voucher ( Canada included )

Allan

Ed

Posted

Legacy Member

Manager of municipal pillar drills

Last edit: by allan downes

Last edit: by allan downes

Posted

Site staff

Ed

Posted

Full Member

Hi Rob,Hi John,

Like you I bought a stand for the Dremel but sadly it's far too inaccurate for the sort of stuff that we do modelling wise.

Last Christmas my good lady bought me a Proxxon mini pillar drill which is superb for drilling accurate holes. I invested in a compound table for it which allows me to minutely adjust the position of the work piece. That added to the overall accuracy of the drill press itself make it a winner for me.

You have one of the good ones. Collett centering (lack of) is an issue with these units. I've got better out of the bench press or even the Dremel (at 5000 rpm, not exactly the right speed for drilling metal). Expect to pay 5 times more for a precision mill rather than a drill.There are actually very few times when you need machine shop reproducible accuracy for holes.

Nigel

©Nigel C. Phillips

1 guest and 0 members have just viewed this.