Electrics DCC

Posted

Full Member

wiring droppers

That's the way I did all mine Shaun, but keep the iron 'tinned'!Cheers

Ron

Proper Preparation makes for Perfect Performance!!

http://yourmodelrailway.net/view_topic.php?id=13331&forum_id=21

http://yourmodelrailway.net/view_topic.php?id=13331&forum_id=21

Posted

Full Member

I`ve done a lot of soldering droppers to track of many gauges and recently I`ve wired up a 7mm layout in my shed.

Soldering does`nt need to be a nightmare……..

droppers to track…………………………………………………………………………………………………………………….

a clean hot iron 25watt or 40 watt

a decent flux essential it should make the solder run immediately, if it does`nt it`s the wrong one.

don`t use cored flux solders.

A heat sink either side of where your soldering your dropper to reduce the damage to plastic sleepers.

two cheap paintbrushes. One for the flux. One to clean off the flux with water.

The result……..

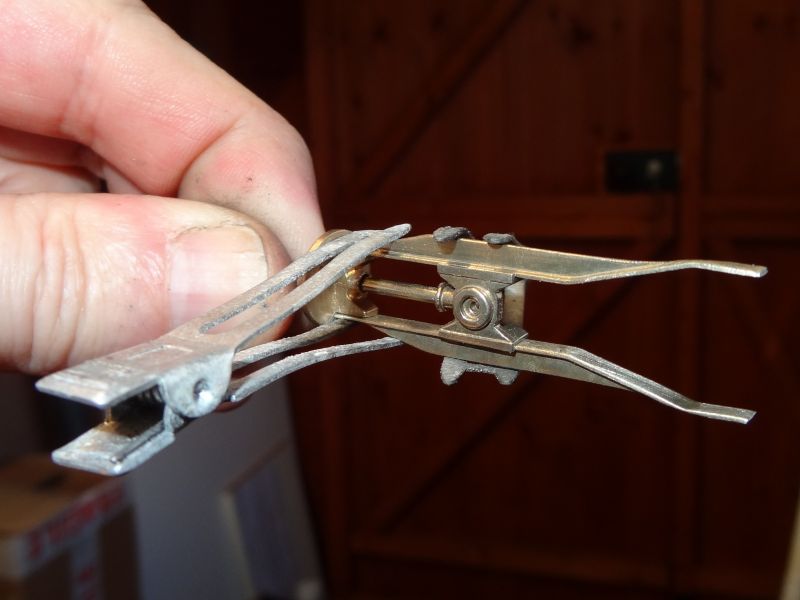

The heat sink……. the best modellers right hand……… Hair clips……..

All you need to solder successfully……………………………………………………………….

The Green flux is similar to Bakers fluid and both are good for most modelling jobs.

The `sooty` pot on the lower left is a soldering iron tip cleaner/tinner and will keep your soldering tips at the ready forever………..

hope that helps

John

Twobolt John

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

No one has or will criticise anything you do on here, but as you know, will always offer up hints from their own modelling experience in response to your questions. Always remember that there is rarely a definitive way to do anything, just choices to consider. Oh, and one should also bear in mind that advice seen here will usually be streets ahead of what is on You Tube! Personally, I usually take 'advice' seen on YT with a generous portion of salt!

Where opinions vary, just try them and see what works best for you. Job done, haha :)

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Inactive Member

I'm not familiar with rating wire by Amps - rather by diameter.

My droppers are 1.0 mm solid copper from the rail to just under the base board. Then stranded 1.0 mm multi-core copper to the bus, which is 2.5 mm stranded.

Considering that the DCC systems are typically rated at 5 Amps, it sounds like you have made a wise choice. :thumbs

Carry on - that man!

Max

Port Elderley

Port Elderley

Posted

Inactive Member

So at 15v you're safe for about 80 Amps…

1mm wire @ 240V is rated for about 10 A or 2400 watts (worst case buried in insulation)

at say 15V it should be able to take somewhere near a little less than 160 Amps so I think you're very safe there.

2.5mm wire @ 240V is rated at maybe 18 A or 4320W

so at 15 V you should be able to run 280 ish amps very very safe there

I know I've not allowed for the differences between AC and DC and frequency effects but at what we are going to run things it's near enough!!!

Last edit: by The Q

Last edit: by The Q

Now I've finally started a model railway…I've inherited another…

Posted

Full Member

Hi Kevin,Hi All. Unless I have not seen the comment? It would seem that no one has criticised my choice of dropper wire,being 5 amp wire that has been stripped from "lighting cable", I expected comments like "I was being mean" and "why not buy new wire". that is meant to do a "proper job" and "it is cheap enough".. all the best. Kevin

Whatever works for you is correct.

Nigel

©Nigel C. Phillips

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Inactive Member

Max

Port Elderley

Port Elderley

Posted

Full Member

Staying on the thread Kevin.

Posted

Inactive Member

) would have to be able to run an old fashioned 120W bulb and that would run about 8 amps at 15V (the 19V peak of DCC is not continuous but a series of pulses so I allowed for that)

) would have to be able to run an old fashioned 120W bulb and that would run about 8 amps at 15V (the 19V peak of DCC is not continuous but a series of pulses so I allowed for that)More likely the correct wire 0.5mm flexible wire rated at 3 Amps@240V = 720W or 48A at 15V or to be really picky,

36A at 20V to allow for DCC going wrong and giving a full continuous voltage.

note IIRC most mains wires are actually rated at current * 250V but that is going a bit too deep for this.

Last edit: by The Q

Last edit: by The Q

Now I've finally started a model railway…I've inherited another…

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

You can get all correct dropper and bus wire you need from…………………..

expressmodels.co .uk

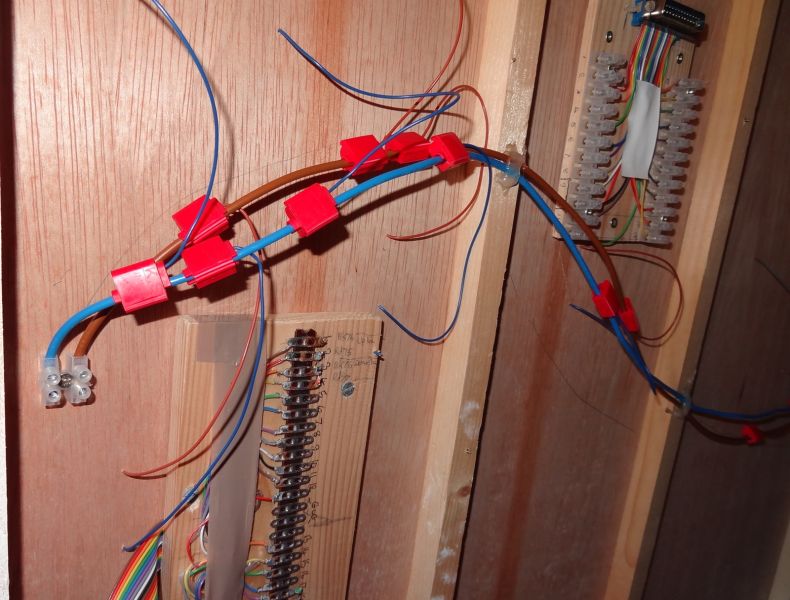

I also use their non soldering wiring kits……..

Although, if you used the non soldering `suitcase` clips` I would just get the wiring from express models and the clips from…….

farnell element14 UK……. because they are double bladed…….

I , absolutely, hate soldering wires under layouts …………

Cheers

John

Last edit: by Twobolt

Last edit: by Twobolt

Twobolt John

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

I used to learn a lot from all the modelling mags in the 60`s, 70`s and 80`s

Nowadays, I learn most things on modelling forums such as this.

There`s nothing wrong with asking questions mate……

cheers

john

Twobolt John

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

DCC Power bus lead. 3.3mm dia rated at 21A. Price is per meter.

EX/PBUS(A) Brown.

EX/PBUS(B) Blue.

Layout wire. o.2m dia. To connect to track. Price is per meter.

EX/PBUS(F) Brown

EX/PBUS(G) Blue.

Actually Kevin, I learnt about an easy way of wiring a layout for DCC from an Australian modeller called Olliead who did a YouTube blog…..

Cheers

John

Last edit: by Twobolt

Last edit: by Twobolt

Twobolt John

1 guest and 0 members have just viewed this.