New part work

Posted

Inactive Member

Posted

Inactive Member

Posted

Inactive Member

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Full Member

it was already on fire when I got here, honest!

Posted

Inactive Member

Posted

Inactive Member

Posted

Inactive Member

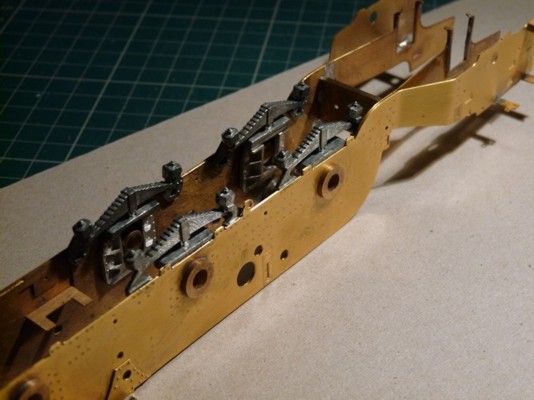

Main Chassis: Fitting of rear and centre springs and rear and center horn blocks and repaired a broken solder joint on the rear chassis inner bit.

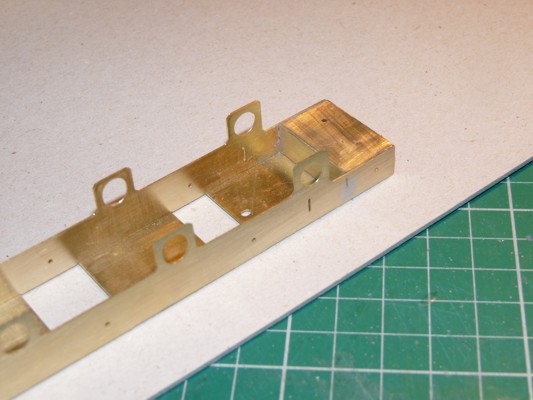

Tender Chassis: Fitting front and end spacers and soldeing it all up. The trickiest bit was soldering the nut onto one of the spacers without soldering up the thread as well. I did but was able to re-thread it with a set of taps and dies.

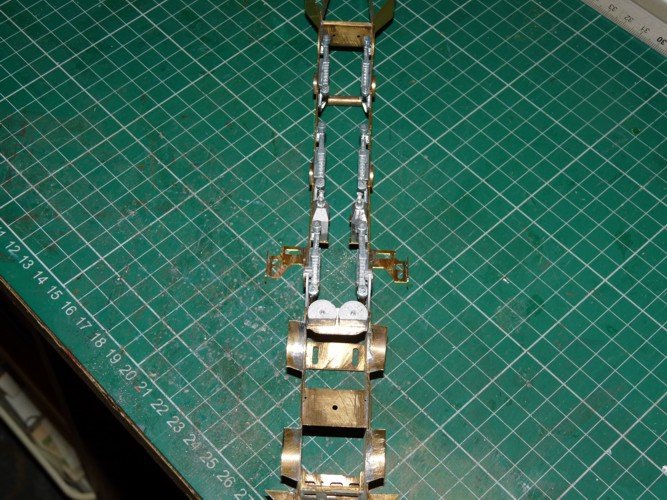

The springs and hornblocks in place

Tender innder chassis spacers in place.

That's it for now folks. Come back soon for another thrilling instalment.

Posted

Full Member

Terry

Posted

Inactive Member

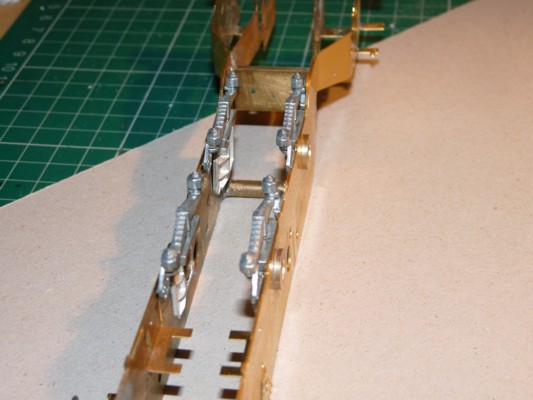

Chassis from the front and downside up, showing all the hornblocks, springs etc.

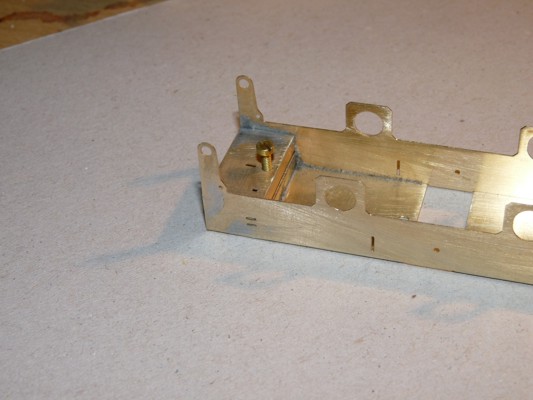

The rear spacer in position.

Next wet day (I'm out with camera on dry ones), I will carry on with the tender inner chassis. Will keep you all informed.

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Inactive Member

Herewith the results. They still have to be cleaned up yet but next week there are more bits to add for the brake gear so will leave the cleaning till then.

The bits of wire pointing skywards near the centre axle bearing holes is a rudimentary springing system when the wheel bearings and wheels are fitted.

More later.

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Site staff

You've mentioned you super glued the brake cylinders and air tank, any reason why you didn't solder these?

Ed

Posted

Inactive Member

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Inactive Member

Posted

Inactive Member

The body so far, resting on the chassis

Side shot of body

The chassis so far

More later.

Posted

Inactive Member

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Full Member

Keep up the good work! Cheers, Pete.

it was already on fire when I got here, honest!

Posted

Inactive Member

1 guest and 0 members have just viewed this.