New part work

Posted

Full Member

I wonder if such things don't harm the hobby since the erstwhile modeller is likely to be put off doing metal models in the future.

A 0-4-0 industrial loco would be a better starting point (I believe DJH do at least one), but it wouldn't have the cachet of a Pacific.

John

John

Posted

Inactive Member

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Full Member

John

John

Posted

Inactive Member

A little more cleaning up to do then it can be put away till next needed.

Next episode next week sometime.

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Full Member

John

John

Posted

Inactive Member

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Full Member

Posted

Inactive Member

Posted

Full Member

John

John

Posted

Inactive Member

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Inactive Member

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Inactive Member

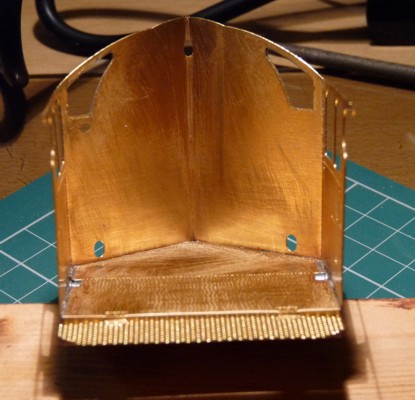

Anyway, here's a pic of today's progress.

The nose cone showing the four drilled holes for the lamp brackets.

Next weeks parts are the boiler and some more detail parts and hopefully the eight screws that should have been in this weeks issue. It looks like the body screws together to make one solid unit.

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Full Member

I suspect, as time goes on, you'll get just a coupling rod one week …………:roll::roll:

Throwing some "good stuff" in early on in the series, hooks people so they continue to buy. Once they get so far down the line, backing out is not an option so they start to put the insignificant parts in on a weekly basis. That's when they make their money …………:roll::roll:

'Petermac

Posted

Inactive Member

Posted

Inactive Member

This thread will keep us all entertained over the journey. :thumbs

Max

Port Elderley

Port Elderley

Posted

Inactive Member

Posted

Inactive Member

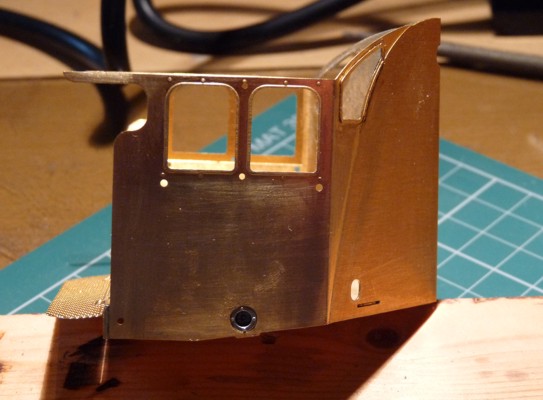

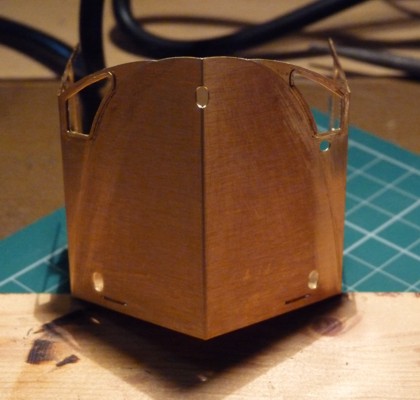

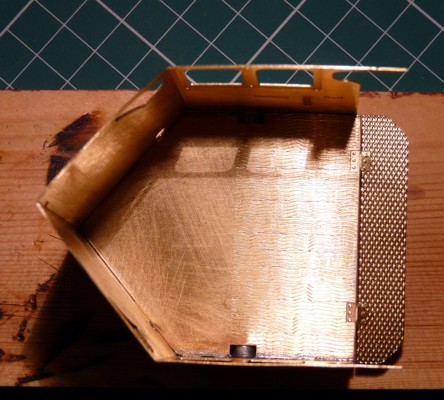

Here's the pics so far. The cab has not been fixed down yet. It is only resting in place to give some idea of what it will all look like eventually.

That's it till next week when the next offerings will be some more bits for the cab.

Last edit: by 60019Bittern

Last edit: by 60019Bittern

Posted

Full Member

Posted

Inactive Member

Posted

Inactive Member

1 guest and 0 members have just viewed this.