NEM Pockets ......

Posted

#264291

(In Topic #14388)

Full Member

I need some NEM pockets to enable me to replace both the huge D type TL couplings and some of the older "non pocket" type coupling.

With pockets, I can use either Kadees or "plug-in" slim-line TL couplings. I also have some stock which, probably because they once had 3 link couplings, have no couplings at all.

It's a veritable minefield out there !

There are pockets for Dapol, pockets for "old" Mainline, those for Hornby and Lord knows how many other variations

I just need that box into which one plugs a coupling. I don't want the "fishtale" and I don't want a different box for every piece of stock I own ! I just want a box (pocket) that I can glue onto the underside of any make of stock ( having carried out any necessary "siting issues" depending on the make / type of coupling currently fitted) into which I can plug a coupling as detailed above.

Can someone who has the necessary experience, please point me in the right direction…… :roll: :roll: :roll:

'Petermac

Posted

Full Member

I had the same issue. I bought a pack of small D couplers with NEM sockets which could be glued into place and, in my case, discarded the D coupling and replaced with a Kadee coupling. As I recall, they were Bachmann ones as they allegedly have a tighter fit than the Dapol, although I cannot say whether this is true. However, a quick search of Ebay shows a couple of enterprising 3D print versions of just the socket, which can be glued or screwed in place and they come with shims to help with height adjustment. I can put in a link if you are interested.

Michael

Posted

Full Member

This is an annoying area of incompatibilities. As I understand your question you need the blank NEM pocket which has a male dovetail at the rear, the female partner of which being already in situ on your rolling stock.

If so, I think you need to buy either Hornby X6354 (but to be honest I don't like the dovetails on these - flimsy) or the more expensive Bachmann equivalent but these are a combined coupling and pocket so you throw the couplings away.(36-027 or 030).

If I don't have NEM pockets already installed then I favour putting on the Kadee box type rather than NEM pocket type, saving this latter type for when I'm swapping over an existing NEM fitted piece of stock. It works out cheaper I've found and equally effective.

If you need both the pocket and dovetail parts, then there's even more reason to install the Kadee box type.

Colin

Posted

Full Member

E-bay could present a problem over import costs and postage charges for me Michael. Having said that, Liz will be in UK in July and could bring 'small' things back with her. However, July is half a lifetime away……..

The dovetail is what I don't want Colin. Only relatively modern stock has that type of mounting. I just want the plain pocket which I could glue to any make of stock.

The Kadee gearbox only takes Kadee couplings (AFAIK) whereas a plain pocket would take a Kadee or plug- in type small TL. The No 5 (?) Kadee gearbox has the coupling permanently fixed during assembly. I want the capability of changing the coupling to a TL at will……….

'Petermac

Posted

Full Member

I use both Bachmann and Dapol pockets. I find Bachmann are a pain to stay glued either direct to the wagon or to height adjusting shims.

Dapol are more secure - I think they are cheaper as well. They take the standard Kadee coupling and most fishtail tension locks - not all, but I can always find one from what is now a very large stock.

They have a tail attached to the box as part of the Dapol system butit is easyto snip off and doesnt affect the integrity of the box itself.

HTH

Posted

Full Member

When I wrote “ more secure†I was referring to the Box staying glued to the wagon not the degree to which it secures the fishtail.

Some tension locks can fit too loosely in Dapol boxes - you have to dig around to find one that holds tight. However I have never had problems with securing kadees in Dapol boxes

Posted

Full Member

I too have had the odd problem getting the Bachmann ones to stay stuck. I thought it was just me, or my glue, so perhaps that is another consideration Peter. All Kadees (well those NEM ones) have fitted fine, and I can swap them over for the small D tension lock if I so desire.

Michael

Posted

Full Member

It seems everyone else understands this discussion but me, must be the sudden onset of cold weather here.

(Note added later: Perhaps it would have helped if I'd read post #1 correctly? Doh! I'll leave the rest below even though I clearly missed the point. What follows might still be useful to someone starting from scratch)

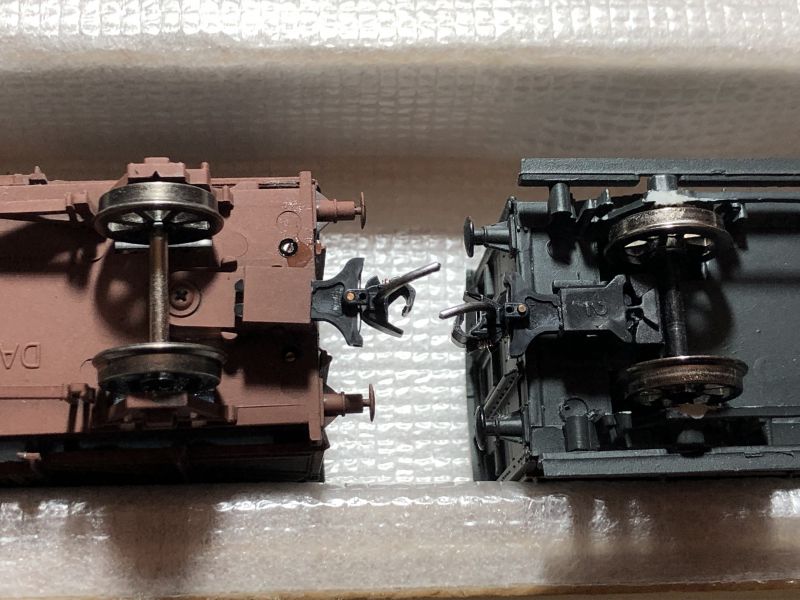

To aid my understanding this is a photo of the gear on a Dapol (L) and Bachmann(R)

Both types are screwed to the chassis with different design mountings, the only common part being the NEM pocket at the front which should be (but isn't) of standard dimensions to meet the NEM standard.

In the case of the Bachmann the rear mounting is the dovetail socket, fixed by a screw to the chassis allowing the pocket sideways movement via the dovetail connection. The Dapol design of NEM pocket pivots due to being held by the central screw, constrained by its fixed mounting plate.

Where I'm confused is by the various references to gluing the pocket directly to the chassis e.g.

"I just want the plain pocket which I could glue to any make of stock." etc.

surely this would mean it would be rigid and you'd get couplings locking up on curves. These pockets are designed to attach into a matching mount which allows for some lateral movement.

If you're starting with a wagon devoid of any mounting point then the Dapol option (COUPNEMOO) strikes me as less attractive. You get the NEM pocket, its mounting plate (allowing the restricted sideways movement), a screw (+ an unwanted mini D coupling). What is still missing is the mounting point for coupling/ screw which comes moulded as part of the wagon and is designed to hold the mounting plate and the pocket in place. I can imagine that'd be hard to replicate. Here..

Much simpler but more expensive would be to buy the Bachmann NEM pocket and coupling 36-030 and also the corresponding mounting device, a Parkside item PA34. This latter item is easily screwed to a plain chassis underside with a small screw of your choice. The underside of the PA34 has two bars which can be cut back to adjust the height setting. This is the path I've chosen for fitting to various older style RTR models, most Hornby with those big "D" couplings and to kits.

I think it was Nigel some time ago who advised against gluing any coupling device to the chassis because of the impact shocks and knocks they incur, consequently I always screw mine down nowadays. (maybe that was WRT Kadee gearboxes?)

If you want to glue then the PA34 is made from Polystyrene so should glue well with a standard PS cement of your choice.

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

A surprising amount of my older goods stock have NEM pockets glued either directly to the underside of the van or, more typically, glued to a block made of layers of plasticard. The layers in the block being adjusted to ensure that the kadee is at precisely the required height

Having virtually all the stock with NEM pockets of the correct height means you can change the composition of a rake by swapping kadees with slim line fishtail tension hooks. I believe this is what Peter is trying to achieve.

Provided one doeasnt insist on ultra close coupling I have not found the absence of a swivel motion causes buffer lock.

Nigel is correct regarding the downside of glueing box to body/mount. A sharp horizontal tap (as in shunting) can break the glue bond :twisted: . Hence my comments about Bachmamm NEM boxes. I spend more time than I would wish glueing boxes back on. Its a chore I put up with in return for the advantages of interchangeability and uniform coupling height. Its a solution that is probably not for the purist but then I have always maintained I am a "coarse" modeller.

Posted

Full Member

That helps clarify my misunderstanding. Given this, I've added a note to my earlier post.

It is interesting that you can get away with using fixed NEM pockets, something I'd never considered. I guess with the extreme curves on Weston-Heathfield I might well get problems but they will disappear with the move to Upper Hembury.

Maybe the Bachmann NEM Pockets are made from polythene in which case gluing will always be problematic?

Colin

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

Parkside Models PA34 NEM Coupling mounting points - to allow NEM

This still leaves the problem of sourcing the NEM pockets. I usually buy the Bachmann tension lock couplings complete with pockets, which gives me spare couplings if I am using another type in the installation. That then allows me to gradually replace Hornby tension locks with the Bachmann ones (which are the better of the two, in my opinion).

Jeff Lynn,

Amateur layabout, Professional Lurker, Thread hijacker extraordinaire

Amateur layabout, Professional Lurker, Thread hijacker extraordinaire

Posted

Full Member

From a post of mine in 2013. I used Bachmann TL connectors with fishtail pocket (they are close to NEM 362 specifications but not exact), and Parkside Dundas fishtail pocket mounts (now PECO).

One thing I learned was that screwing is definitely better than gluing - many of the older model chassis are nylon or similar, which doesn't take kindly to many glues. The Parkside Dundas mounts fell off after a couple of years. The other thing was that the fit between the Bachmann fishtail and Parkside Dundas mount was fairly loose, and often came apart on running. A slightly loose screw mount allowing the pocket to swivel would be better. The fishtail flexible connector has advantages over a fixed connector - goes round tighter curves better.

I've since tried the 3D print pockets (:???:). I resolved the TL/NEM 362 swap by keeping a TL on one end, and a NEM 362 on the other end of a wagon.

Nigel

©Nigel C. Phillips

Posted

Site staff

Just my thoughts

Cheers

Matt

Wasnie me, a big boy did it and ran away

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

Posted

Full Member

Many thanks indeed. :thumbs

'Petermac

Posted

Full Member

The location is a direct equivalent to where Hornby position one of their chassis screws, for example on the 2019 Terrier and others, viz.you have to pull the NEM pocket off just to access them!

That seems to me the simplest and most secure way to fix NEM pockets firmly in place to stock which lack a built in mounting..

Posted

Full Member

Terry

Posted

Full Member

I'll have a re-think and do further research. :thumbs

'Petermac

Posted

Full Member

Posted

Full Member

'Petermac

Posted

Full Member

At the risk of sounding like a broken record, I'll try to better make the case for not gluing these mounts.I'll almost certainly be glueing some of mine John - others, I might manage with screws but I'll need to hide the screw inside box vans etc…….

John has already pointed out how annoying it is when direct glued pockets inevitably break. Bonding plastic to plastic is fraught at best and the join is not shock resistant unless polystyrene to polystyrene. Getting the height correct in a one-time install must be tricky as well. No "undo" arrow available.

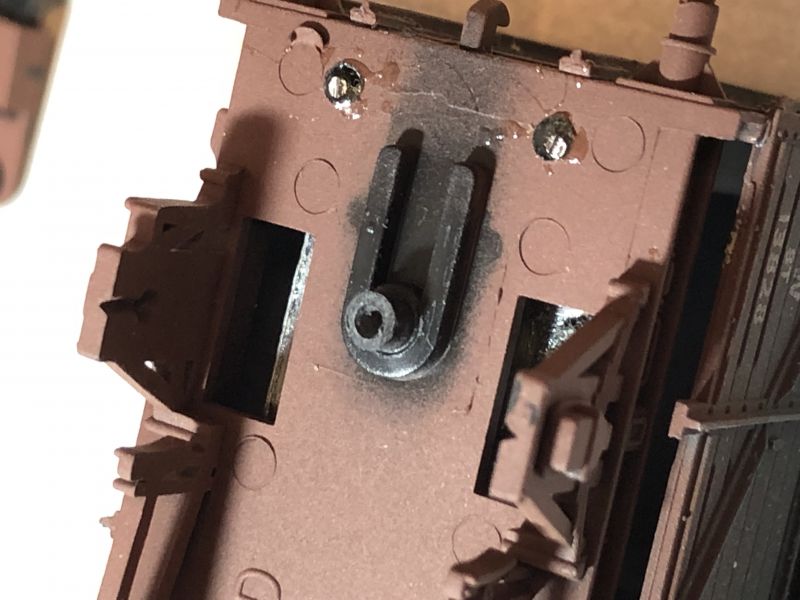

Screwing down a suitable mounting point then using a Dovetail ended NEM Pocket is IMO the easiest way, also avoiding "Dapol Droop". This attach photo and insert shows how:

The main photo shows a Bachmann wagon with its onboard NEM mounting point. Here it is moulded in and the screw simply holds the under-frame and body together.

In the absence of such a mounting, instead use the PA34 (inset), shim or trim if required to adjust the height and put the screw hole through the front section. There is plenty of depth to get this screw engaged in the available depth of the body. The Bachmann NEM pocket may sit a tad loose in the PA34 but if so, easily fixed with a tiny dab of thick CA.

1 guest and 0 members have just viewed this.