Peco Bullhead Track

Posted

#246939

(In Topic #13636)

Full Member

Useful tool, PECO ranting.

Despite my previous misgivings about using Peco products after my experience with 'Technical Help' and their seemingly blasé view over customer choice and consultation, I have nonetheless bought lengths of Bullhead flexitrack as I can't go through the mind-numbing excercise of respacing the sleepers on finescale.It does look good, but is quite delicate, and easy to spoil with heavier handling. My 15% Expressways Models discount as an active S.D.R. volunteer takes bit of the sting out of it!My dilemma is that only large radius L & R turnouts are currently being produced, and the the response 'Don't know when we will get round to producing more….we're very busy….' isn't exactly helpful. As I have a small stock of Code 75 turnouts, some still unused, I am prepared to use them and 'Technical help' told me to 'force' the end of the bullhead into the Code 75 joiners, as there are currently no plans to make an adaptive joiner either. [See 'Don't know etc above…']

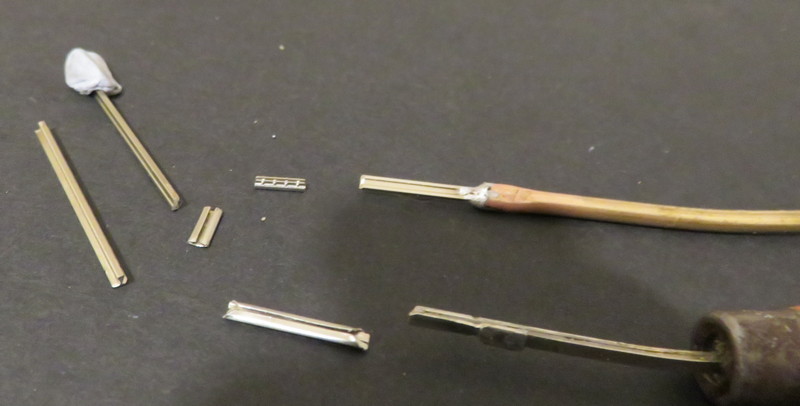

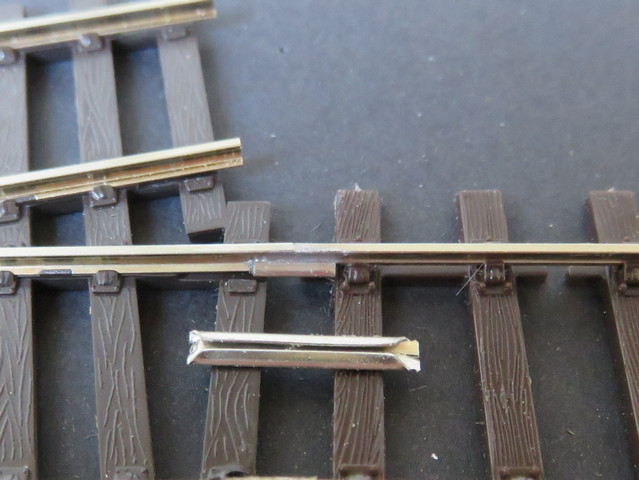

Diabolical! That's the only polite way I have of describing the effort and ghastly effect. They look pretty piss-poor on code 75, on bullhead finescale they are laughable, so I have started to cut Code 75 joiners in half and remove the 'ramp' at the ends using my Dremel, and soldering the bullhead and the Code 75 turnout rail together to create a secure joint. Handling a normal sized joiner is bad enough, when less than 5mm long it becomes more problematic, espcially it you are trying to 'force' one end onto bullhead, and the other onto Code 75, so I have come up with a Mark 2 Chubber Putter-onner made from a length of brass tube and a scrap of bullhead rail. There's a drawing pin head soldered to the other end to protect the palm of your hand.

In use I open up one end of the shortened joiner with the Mk 2 and use the Mk 1 to push it onto the track before joining them. A touch of Fluxite and a quick in-and-out with a 25 watt iron does the trick.

'Ah!' I hear you say, 'what about the isolating joiner at frog ends…', well it is my intention to use a very fine cutting disc on the turnout track, the resulting gap to be filled with epoxy or similar.

From L - R,

Code 75 rail,

bullhead rail,

cut down joiner,

Peco bullhead joiner for b'head to b'head,

below an ordinary joiner,

top right the Mk 2 tool

and below the Mk 1 tool for code 75.

I hope that might help somebody else,

Poop-poop,

Douglas

Last edit: by Chubber

Last edit: by Chubber

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

Douglas

Last edit: by Chubber

Last edit: by Chubber

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Site staff

Ed

Last edit: by Ed

Last edit: by Ed

Posted

Full Member

Michael

Posted

Full Member

We have come to expect nothing less! :patheadVery smart indeed!

Michael

Posted

Full Member

I thought you were going SMP points? I have not understood why Peco did introduce other turnouts either. Next year at the earliest.

Nigel

©Nigel C. Phillips

Posted

Full Member

The code 83 joiners from Shinohara or Micro Engineering look about the same size as the "half" joiners.

I thought you were going SMP points? I have not understood why Peco did introduce other turnouts either. Next year at the earliest.

Nigel

Well, Nigel, having revisited Ben Alder's brilliant 'Far North' where he is using C&L track with Peco turnouts, I decided that already having 5 of the 7 turnouts I need [two unused] and the associated packing I decided that Peco b'head flexitracks spacing would give me the same effect. Having formerly lived a few years in France, I did tend to over-buy during my U.K. visits.

If the result is half as good as 'Far North' then I'll be a happy chappy!

Poop-poop,

Douglas

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

1 guest and 0 members have just viewed this.