Mike's Scrubber

Posted

#196865

(In Topic #10926)

Legacy Member

an electrified wheel cleaner from bits and pieces...

Thought I'd share this with you….Whilst waiting for an order to arrive from Hattons I decided to waste a few hours building an engine cradle out of odd bits and pieces (yes I know I said 'wheel cleaner' but read on)….

Sawing up a few bits of scrap mdf, slicing an old now unused foam exercise mat, a few panel pins and a spot or two of pva, created this servicing cradle;-

Musing over a brew I thought what I really need now is a wheel cleaner to use on locos in said cradle, could I manufacture something from more bits and pieces I'd got laying about, something I could just plug into 12vDC and give the wheels a bit of a going over so to speak.

In my odds 'n sods box I'd a few small wire wheels fitted to shafts - like the ones you get with a rotary drill set for burnishing metal and, as they were all metal they'd conduct power so, if I could make some form of keeper to hold them on the wheels of a loco in the cradle it might do the trick.

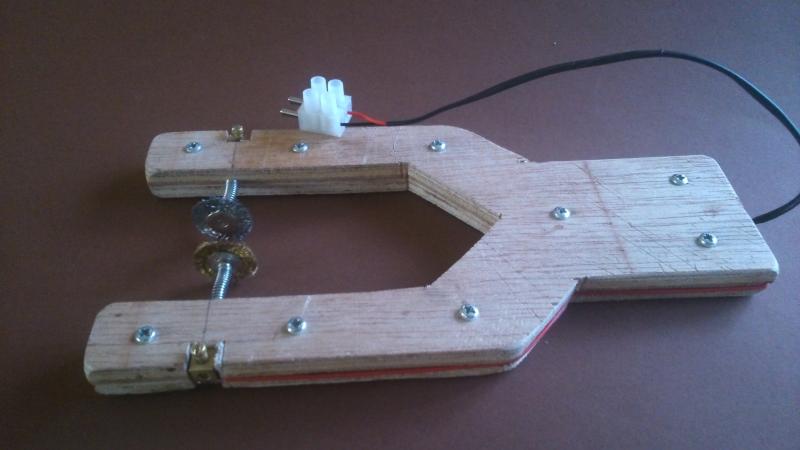

Introducing 'Mike's Mark I Scrubber' my stab at an electric wheel cleaner - ta da……

With two ends cut from the poles of a defunct 13amp plug, two aforementioned wire wheels, springs from two gash biros, bit of wire, some ply, pva, a two gang plug in connector, some small screws and wallah - my MkI Scrubber….

The wheels obviously don't spin as they're held in position by the two 13amp plug thingymajigs, the springs keep them centered at about 20mm and also stop them sliding back out of the retaining slots - if they get dirty its a simple job to slacken off the screws and turn them slightly and, if over time, they become completley gunged up, I'll simple swap them for two new ones.

Bit crude but as I said it's a Mark One and no doubt some of you more experienced engineering types could do a great deal better but, plugged into a 12vDC supply it works brilliantly and the best bit like the cradle, they cost me absolutely nothing apart from a bit of time….

Some more images of the completed Scrubber…

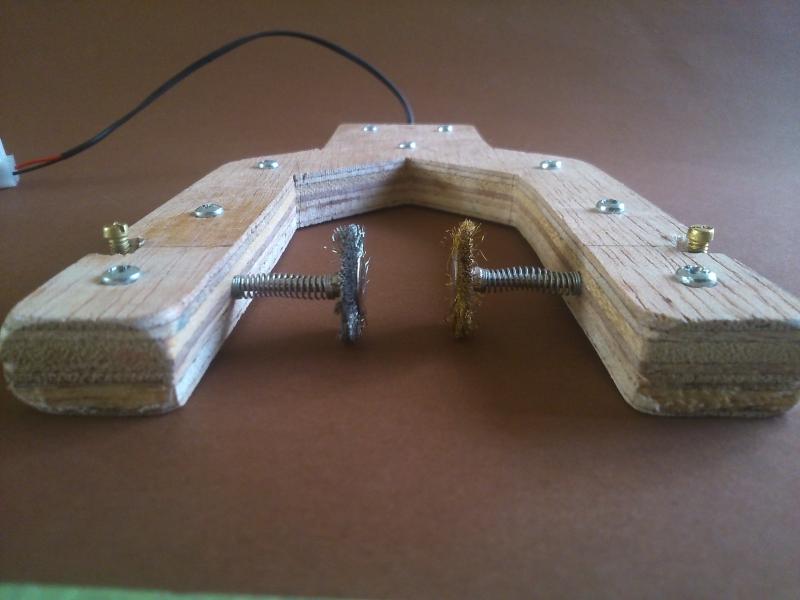

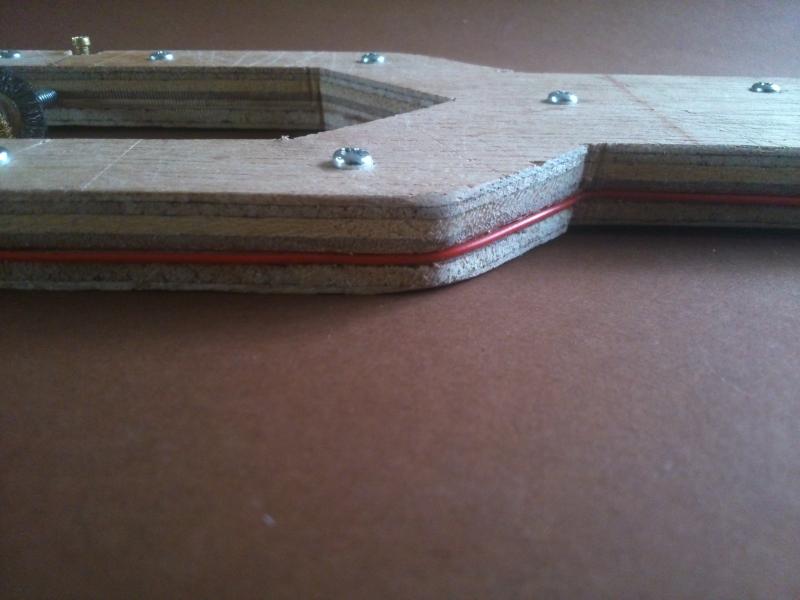

The Scrubber frame is made of two pieces of plywood which, before they were glued and clamped together, had one edge bevelled at about 45degrees to make a slot to super glue in some thin wire after the two bits were assembled.

I soldered the tinned ends to the 13amp thingymajigs, pulled the wire tight and spot welded the wire into the slots with dabs of superglue.

On t'other end I put a slot together connector after heat shrinking the leads to keep them all nice and tidy.

And finally one of my creations in action 'scrubbing' I know it's not a video but the wheels of the loco in the cradle are actually spinning round giving themselves a right old going over - nice and clean again… super job for no outlay, brill…..

This one is for 00 but an adjustment in the sizing could create one for virtually any other gauge.

Other electric wheel cleaners are available (but, I must hasten to add, not at this price) :shock:

Last edit: by 16A

Last edit: by 16A

Mike

Praise is an excellent fillip for waning ambition.

Praise is an excellent fillip for waning ambition.

Posted

Full Member

Clever stuff Mike but I expected to see something female …………………….

thumbs:thumbs

thumbs:thumbs

'Petermac

Posted

Site staff

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Legacy Member

It's all in the mind Peter…I expected to see something female …………………….thumbs:thumbs

Another thing I found the Mk I is capable of doing - if you're careful, it will clean the insides of the wheels where the pick ups make contact, an added bonus…..

Mike

Praise is an excellent fillip for waning ambition.

Praise is an excellent fillip for waning ambition.

Posted

Inactive Member

I like it……put me down for a MkIII…..that`s the one with racing stripes

:cheers Gormo

"Anyone who claims to have never made a mistake, never made anything!!"

https://sites.google.com/site/greatchesterfordmodelrailway/home

https://sites.google.com/site/greatchesterfordmodelrailway/home

Posted

Full Member

Neat idea. Beats my suede brushes connected to the DC power pack. Is one polishing wheel brass wire and the other steel wire? If so you might want to consider having both of them soft brass. Those engine wheels are going relatively slowly (when compared to the 8,000-13,000 rpm of a Dremel or similar), it might reduce the potential for scratches on the drivers (which are I believe are nickel-silver = hard brass alloy).

Nigel

©Nigel C. Phillips

Posted

Legacy Member

In my defence during the research and development phase I only had one of each type with a shaft narrow enough to pass through the recycled 13amp retaining assemblies, also MkI was only ever intended as an experimental product to prove a concept. However, now the proving stage has been successfully negotiated and the requirements of the design phase have been accomplished, I have instructed the aquisitions department to obtain (almost said 'buy') some all brass replacements of the appropriate dimensions for a product upgrade. Paint and racing stripes are also being obtained to satisfy the demands of the ever increasing customer list…..

Mike

Praise is an excellent fillip for waning ambition.

Praise is an excellent fillip for waning ambition.

Posted

Full Member

Looking forward to the turbocharged S-version. No checker go-faster tape please. Micro-scratches on track or drivers = reduced traction - up to 15% according to the highly controlled studies I carried out on a piece of scrap track, a Heljan Western and some string and assorted lead weights. I would imagine more with a 6-wheel steam engine with a reduced number of traction points. The smoother the surface the better the traction.

Nigel

©Nigel C. Phillips

Posted

Legacy Member

Some of us better keep our cloth caps on then !!! :shock:The smoother the surface the better the traction.

Last edit: by 16A

Last edit: by 16A

Mike

Praise is an excellent fillip for waning ambition.

Praise is an excellent fillip for waning ambition.

Posted

Full Member

No, no, use it for polishing the track (or rub the wheels over your head). Or is it the other way around…….

Nigel

©Nigel C. Phillips

Posted

Full Member

Foster.

Posted

Full Member

Traction tires? Do locomotives still come with them? I got rid of all of mine years ago when spares became difficult and I installed proper wheels and some additional weight. Not sure they are necessary with a decent decoder.

Nigel

©Nigel C. Phillips

Posted

Full Member

Yep, traction tyres!

I found it hard to believe too!

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

1 guest and 0 members have just viewed this.