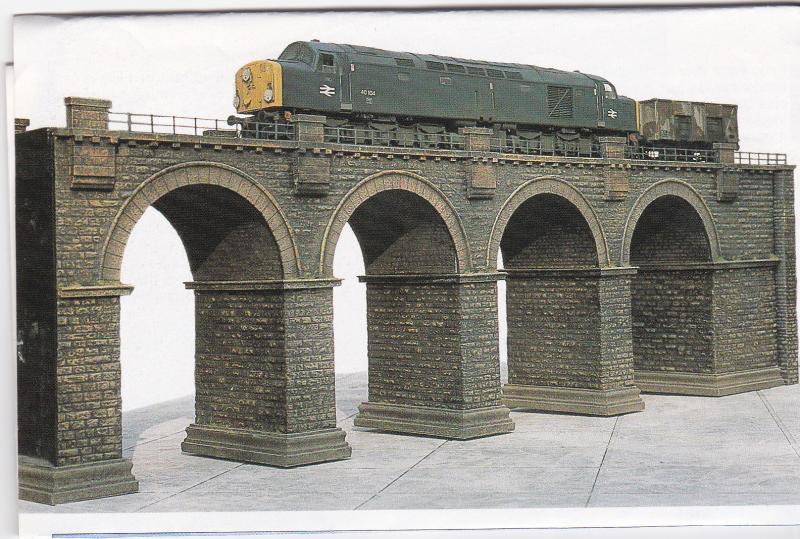

Bewdley Viaduct

Posted

#158519

(In Topic #8937)

Inactive Member

© David Meaden

Posted

Site staff

Regards

Alan

Born beside the mighty GWR.

Alan

Born beside the mighty GWR.

Posted

Inactive Member

Regards

David

Posted

Site staff

Regards

Alan

Born beside the mighty GWR.

Alan

Born beside the mighty GWR.

Posted

Legacy Member

Another winner David, thanks.

Allan.

Posted

Legacy Member

Posted

Full Member

'Petermac

Posted

Inactive Member

A major traffic accident and a wayward lorry possibly..

Whenever I write a letter to someone, I add a footnote briefly explaining Ohm's law. It's my P.S. de resistance.

Posted

Legacy Member

Posted

Full Member

Those repairs are only superficial Trev - the structure is massive under the shell and would have remained quite safe. :thumbsMakes you wonder what on earth was holding the viaduct up while they did the repairs and what necessitated such major work.

A major traffic accident and a wayward lorry possibly..

My guess is that, judging from the surrounding stonework, it was to replace badly eroded surface stone. If it hadn't been done, rain would have gradually seeped in and frosts would have "blown" the surface - rather like road surfaces with cracks in them……rain gets in and a couple of hard frosts, and the surface literally blows off.

Brick - at least the "hard" engineering type brick they used there, is far more waterproof than stone.

'Petermac

Posted

Site staff

Regards

Alan

Born beside the mighty GWR.

Alan

Born beside the mighty GWR.

Posted

Full Member

They'd build the main load bearing structure - a sort skeleton of steel or pre-stressed concrete beams - which left huge voids to fill before they could lay the "outer skin" or road. Filling these with reinforced concrete would not only have been pointless because, apart from the costs involved, they take no load but also would be far too heavy for the supporting "skeleton". Most of the empty space was taken up by these huge polystyrene rolls with a fairly thin "skim" of concrete covering them.

You're right in that Brunel's Clifton suspension bridge supporting towers and abutments are honeycomb structures for the same reason - no difference in structural strength and a huge saving on costs. The decking I believe, is not hollow other than for the small "tunnels" built into it for internal inspection of the metal.

'Petermac

Posted

Site staff

Regards

Alan

Born beside the mighty GWR.

Alan

Born beside the mighty GWR.

Posted

Full Member

1 guest and 0 members have just viewed this.