Suitcase connectors for rail droppers

Posted

#222411

(In Topic #12132)

Full Member

Caveat emptor

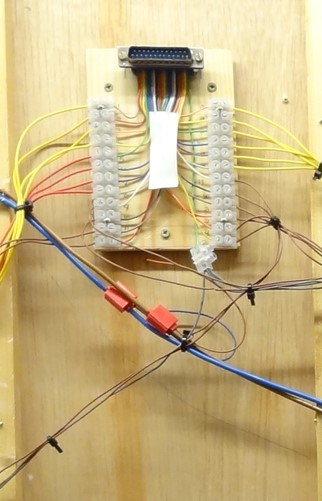

We've had a couple of posts recently on the use of suitcase connectors (Scotchloks, piggy-tails, tap splices) as a means of attaching dropper leads from the rails to the power bus (DC or DCC). They're simple to use, do not require the wire insulation to be removed, and need no special tools. You either love 'em or hate 'em (I like them, but then there's no accounting for taste).They have a major limitation, and that's the wire diameter. Have a look at the 2 photos and see what I mean. Bus wire is normally around 12-14 gauge, 2mm-1.6mm, dropper wires are normally 22-26 gauge, 0.65mm-0.4mm. Tap-splices normally only cover a 4-gauge range. Which is a lot less than the range from bus wire to dropper wire (8-10 gauges). Using for example a 14 gauge bus wire and a 22 gauge dropper wire can lead to the larger diameter wire preventing full contact with the dropper wire, or the cutter not fully going through the insulation of the smaller diameter wire. Pressing the 2 sides together hard enough to make good contact will distort or puncture the casing (bin there dun that) and possibly shear multi-strand wires..

The only way to deal with this properly is to use a 2-step reduction, i.e. 22-18 then 18-14 for 22 gauge droppers and 14 gauge bus wire. All this of course means that grabbing some spare wire without knowing it's gauge/diameter and using suitcase splicers is just asking for trouble down the road. In which case you might want to fire up the soldering iron and save some money…

Nigel

SaveSave

©Nigel C. Phillips

Posted

Inactive Member

Max

Port Elderley

Port Elderley

Posted

Full Member

You're welcome. Use them correctly and they will work fine, but it can get expensive with a large layout using 2 per dropper. I'm reverting to soldered joints, liquid insulation, terminal blocks and Anderson PowerPoles.

Nigel

©Nigel C. Phillips

Posted

Full Member

https://www.rapidonline.com/davico-ds-2m-crimp-blade-splice-33-0190

And these for the droppers

https://www.rapidonline.com/davico-dvpo1-6-3m-6-3x0-8mm-12a-red-pushon-blade-pack-of-100-33-0665

These types of connectors are fine if the correct wire & tools are used.

If a lot of droppers are needed in an area I use

https://www.rapidonline.com/davico-ds-2m-crimp-blade-splice-33-0190

to take wires from the Bus to these type of connectors

http://www.ebay.ie/itm/5pcs-Dual-Row-12-Position-Terminal-Block-Bar-Electric-Wire-Cord-Connector-15A-/271764498709?hash=item3f466d2915:g:nVYAAOSwRgJXk4oO

I then connect the droppers to the connector blocks connected with fork connectors like these

https://www.rapidonline.com/davico-dvf-1-3n-3-7mm-red-18a-fork-connector-pack-of-100-33-0620

"The only stupid question is the one you don't ask"

Regards.

Tony.

Regards.

Tony.

Posted

Full Member

Good stuff (I'm familiar with the spade-type splicer, beloved of automobile and motorbike electricians). Not pig-tail suitcases. Good way to make sure wires of different diameters are not being used together in a splice.

Nigel

©Nigel C. Phillips

Posted

Full Member

I think the reason some have problems with these type of connectors is that they use the incorrect thickness of wire or the wrong tools.

I have quite a few on my layout & only once have I had a failure & that was down to my own negligence.

Tony.

"The only stupid question is the one you don't ask"

Regards.

Tony.

Regards.

Tony.

Posted

Full Member

http://www.ebay.co.uk/itm/4-WAY-EARTH-BLOCK-TERMINAL-CONNECTION-UNIT-alcoltd-com-FREE-FAST-DELIVERY-/121917958224?hash=item1c62e06850:g:JUMAAOSwKtlWj84J

One heavy-duty wire from the bus via Scotchlok to one entry and then simple screw connections for the droppers. You have a choice of 4 and 8-way blocks.

Ebay prices are inflated as they're "post-free", so if you want more than one best to go to your local electrical store where they will be very much cheaper.

Last edit: by RFS

Last edit: by RFS

Robert

Posted

Inactive Member

For those I might have to undo I prefer Wago connectors, not cheap but I find reliable,

https://www.amazon.co.uk/Wago-Compact-Terminal-Connector-Block/dp/B008J1QLS2/ref=sr_1_3?ie=UTF8&qid=1480665052&sr=8-3&keywords=wago+connector+5+terminal

available in 2,3 and five common terminal formats. (thats not the cheapest supplier)

Now I've finally started a model railway…I've inherited another…

Posted

Full Member

The mighty `suitcase connector` ………. the ribbon cable.

same principle…… cable `pinched` between two sets of metal `teeth`

I`ve use them on two layouts over the past 15years, they have been badly abused……….

Do they still work well…….?

…….. of course they do…….

Not for everybody of course….. but find quality products and they can be as reliable as soldered joints

John

Twobolt John

Posted

Inactive Member

I strip it and use it for dozens of jobs. It makes great decoder cable for O scale. :thumbs

And it solders really well, as well.

Max

Port Elderley

Port Elderley

Posted

Full Member

cheers

john

Twobolt John

Posted

Full Member

The issue is not ScotchLok "suitcase" tap connectors per se, it's the use of different wire diameters. I've used ScotchLok-type tap connectors for almost as long as I've been modeling, and they're still going strong. I've yet to find one of these connectors that will take 12-14 gauge wire (2mm-1.6mm) and 22-26 gauge wire (0.65mm-0.4mm), spade tap connections excepted. Unless the blade is closed beyond its design parameters, contact with the smaller diameter wire can be problematic. And not knowing what diameter you are using (as in that You Tube "how to do it") doesn't help. These taps are in general designed for solid wire, there are specific ones for stranded taps.

There is also an issue that users should be aware of with any of these types of connectors, and that is the potential for galvanic corrosion. This is a well known failure cause in automotive applications. The connectors are made using tin-coated brass, there is enough of a difference in electrochemical potential between steel, tin and brass that a humid atmosphere will cause corrosion and interfere with electrical conductivity. I've always had my layouts in humidity-controlled environments, where a difference of -0.5V is acceptable, I'm not so sure about garden sheds or the attic, where it would be nearer -0.25V. The potential difference between copper and tin is -0.3V, throw in humidity and that's galvanic corrosion territory. For those with humid atmospheres (i.e., the garden shed and the great outdoors or no humidity control and hot, humid summers or miserable winters) waterproof taps and steel wire droppers would be a better bet - the potential difference between tin and steel is -0.2V. And if they're cheapo zinc-plated connectors all bets are off, you've just made a battery!

Pressure contacts are legion in the hobby, all the way from turnout stall motors to RJ12 DCC cabling. All have design parameters including wire diameter that we follow. Tony, Robert and The Q have shown that there are many alternatives. Used properly, ScotchLok-type tap connectors work fine for many years. I have them on one of the test track planks, using 2 to allow a proper reduction in wire diameter, although I could probably use the #22-#18 tap and corresponding wire diameters given the low power requirements of 0.5A.

As Max has previously said, the Devil's in the details on this one.

Nigel

©Nigel C. Phillips

Posted

Full Member

That's very interesting Nigel about galvanic corrosion that you mentioned above.Hi John,

The issue is not ScotchLok "suitcase" tap connectors per se, it's the use of different wire diameters. I've used ScotchLok-type tap connectors for almost as long as I've been modeling, and they're still going strong. I've yet to find one of these connectors that will take 12-14 gauge wire (2mm-1.6mm) and 22-26 gauge wire (0.65mm-0.4mm), spade tap connections excepted. Unless the blade is closed beyond its design parameters, contact with the smaller diameter wire can be problematic. And not knowing what diameter you are using (as in that You Tube "how to do it") doesn't help. These taps are in general designed for solid wire, there are specific ones for stranded taps.

There is also an issue that users should be aware of with any of these types of connectors, and that is the potential for galvanic corrosion. This is a well known failure cause in automotive applications. The connectors are made using tin-coated brass, there is enough of a difference in electrochemical potential between steel, tin and brass that a humid atmosphere will cause corrosion and interfere with electrical conductivity. I've always had my layouts in humidity-controlled environments, where a difference of -0.5V is acceptable, I'm not so sure about garden sheds or the attic, where it would be nearer -0.25V. The potential difference between copper and tin is -0.3V, throw in humidity and that's galvanic corrosion territory. For those with humid atmospheres (i.e., the garden shed and the great outdoors or no humidity control and hot, humid summers or miserable winters) waterproof taps and steel wire droppers would be a better bet - the potential difference between tin and steel is -0.2V. And if they're cheapo zinc-plated connectors all bets are off, you've just made a battery!

Pressure contacts are legion in the hobby, all the way from turnout stall motors to RJ12 DCC cabling. All have design parameters including wire diameter that we follow. Tony, Robert and The Q have shown that there are many alternatives. Used properly, ScotchLok-type tap connectors work fine for many years. I have them on one of the test track planks, using 2 to allow a proper reduction in wire diameter, although I could probably use the #22-#18 tap and corresponding wire diameters given the low power requirements of 0.5A.

As Max has previously said, the Devil's in the details on this one.

Nigel

I didn't know that.

If I think the wire being used might be thin for a particular connector I tend to double over the wire to increase its size.

I have never had any problems with the type of connectors I use but I must say that my layout room is very well insulated with only one door & no windows being a semi basement type because my house is built on a sloping site. I also have a dehumidifier on a low setting.

My loft is floored but is a completely different environment being very hot in Summer & cold in Winter.

If I was to build a layout up there I would first have to do a lot of insulation work to make it usable.

Also I might think twice before using these type of connectors in such an environment.

Tony.

"The only stupid question is the one you don't ask"

Regards.

Tony.

Regards.

Tony.

Posted

Full Member

Basic chemistry goes a long way in this hobby. Anytime dissimilar metals are exposed to /humidity/water it happens. One of the reasons sacrificial anodes are used in canal boats. Max and I were in a discussion some years ago about these connectors, and the problems that they have on motorbikes and to a lesser extent cars came up. Most of use don't run model trains in pelting rain, so it's not an obvious issue. My old SAAB was awash with these things under the hood, and required a good clean at the end of each winter due to the spray from the roads. This corrosion did my ECU in, and blew the turbine for good measure through some spectacular over-boost. A $4000 ouch.

This problem would go away if gold-plated terminals were used (as in electronic and audio equipment). Most of the connectors are from the far east, and I suspect the tin layer is micron-thin given its current price. I think it's one of the main causes of poor operation, along with trying to use wires outside the specified diameter. Used properly they're fine. Those of us with air-conditioning and humidity control will never see this problem (mine are now 10+years and working fine, not a trace of corrosion). Garden sheds or attics in a humid climate I'm not so sure about. I'd seal the connectors with liquid insulation or use waterproof ones.

Nigel

©Nigel C. Phillips

1 guest and 0 members have just viewed this.