Base board for a 'plank'

Posted

#218299

(In Topic #11902)

Full Member

Using up sraps pf ply.

As I am in the process of selling up my house in France, I am unlikely to ever have such a big workshop [27ft x 15ft] so I'm using up all my scrap to make 'things'. A few scraps of 2" x 1" softwood and 4ft x 1ft piece of 8mm ply seemed to good to burn so I have made a 'plank' baseboard against the day when I have room only for an Inglenook or similar.As I had about 18"of knot free pine I decided to cut some coving to fit in the corners. I don't think I have shown you this method of cutting coving on a circular saw? You clamp a false fence onto the saw bench at about 45 degrees such that the centre of your piece of wood will touch the sawtooth tips as they emerge through the bed. Taking firm control of the work it is slid across the saw which is raised about 1/8th" between each pass.

A small sturdy tipped blade seems to work best. Eventually the thin edges get too delicate to apply strong pressure to, so stop and plane back the outsides to a feather edge.

As I have no idea what sort of layout will go on it, I have decided to future-proof it a little by concealing ready cut openings for add-on fiddle yards. I hate painting things, and as the ply had been knocked about a bit, I have chosen to cover all exterior faces with wallpaper and then paint it with easy to apply emulsion further protected by a light spray with a cheap aerosol varnish.

I removed the assembly screws from the front edge, relying on the glue and wooden dowels, as Sod's Law says any switches etc will need to be fitted just where the screws are….I papered the back and side faces and painted them with a mix of white emulsion and Windsor blue art acrylic, greyed a little with some Raw Sienna to give a non-committal grey blue.

As France sells 8mm ply but no 8mm plastic section to cover the end and side grain, I chose to make my own from scrap 2" x 1" by repeated passes through the the blade of my small circular saw,then cutting off strips and planing them sqaure-ish before mitring them all around. I stained them black with some redundant bulk printer ink and sealed them with a couple of coats of Kleer.

End

Front

I have left an 'overhang' at the front in case I want to do pushy-pully knobs for point control and fitted six felty feet so that it can sit on a domestic table top without doing any damage.

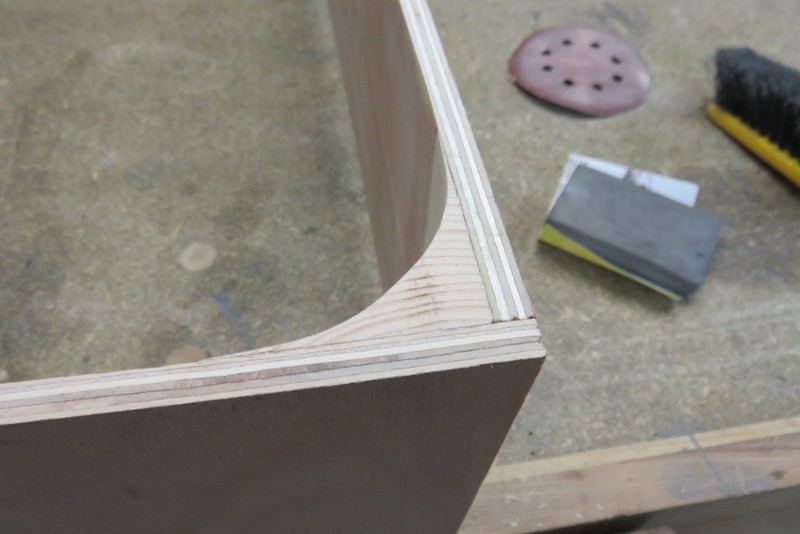

Corner detail

I couldn't think how I'd get rigid wooden section around the curved corners, so didn't try, I don't think it looks too horrid. I'm reasonably pleased with the result, I now have a 47" x 11.5" baseboard ready for that sudden rush of sh%t to the brain!

I hope this has been of interest and has given someone else and idea or two,

Poop-poop!

Doug

Last edit: by Chubber

Last edit: by Chubber

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

Hope you get good use out of it.

"The only stupid question is the one you don't ask"

Regards.

Tony.

Regards.

Tony.

Posted

Inactive Member

You're going to miss your workshop.

Max

Port Elderley

Port Elderley

Posted

Full Member

thumbs

thumbsHow you got those corner fillets to fit so neatly beats me. Are you going to do any more to it pending a sale or will it travel to Blighty like that ?

'Petermac

Posted

Full Member

Very impressive woodworking there Doug. Love the curvy corners, something the experts tell us we should have.

John

John

Posted

Full Member

I have curvy corners but my doctor says I need to get rid of them :mrgreen:Ha! someone else building baseboards without knowing what the track will look like.:Happy

Very impressive woodworking there Doug. Love the curvy corners, something the experts tell us we should have.

John

"The only stupid question is the one you don't ask"

Regards.

Tony.

Regards.

Tony.

Posted

Full Member

John

Posted

Full Member

Terry

Posted

Full Member

Posted

Full Member

Peter, Thanks, and at present I have no plans for the board but I did find myself last week looking through my OO odds and sods thinking 'To Inglenook or not to Inglenook…'

John, it's anti boredom therapy really. Being in the house selling situation for 3 years it's difficult to get enthusiastic about much, no veg garden now that we are caravnaholics and anything I do has to be portable and unlikely to add to removal costs, so another sailing dinghy is out of the question, and a motorbike and side-car will have to wait…

I'm glad I have found Narrow Gauge, particularly as I thought locomotive building would be beyond me, and I have my foray into air-brushing to look forward to in August.

Poop-poop!

Doug

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

Nice plank/piece of furniture. The wall paper bit got my interest as did the concealed holes for the fiddle yards.

Nigel

©Nigel C. Phillips

Posted

Full Member

I have been without internet and VOIP phone for a week, despite 40 Euros worth of telephone calls trying to sort it on my mobile…..

Lots of catching up to do, but at least I've caught up on my reading and I've learned how to assemble Greenwich narrow gauge couplings…[shudder…]

Doug

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

Greenwich couplers, glad you got them working. I gave them a try when I was doing OOn9, switched to Micro-Trains N-couplers or Kadee HOn3 #713/#714, which have delayed action. Not cheap though. I did try the electromagnet system for Bemo couplers, OK but of course no delayed action as it just lifts the coupler up.

Nigel

©Nigel C. Phillips

Posted

Site staff

Regards

Alan

Born beside the mighty GWR.

Alan

Born beside the mighty GWR.

1 guest and 0 members have just viewed this.