Old Triang Wagons

Posted

#209199

(In Topic #11440)

Site staff

Recycling for the sake of it?

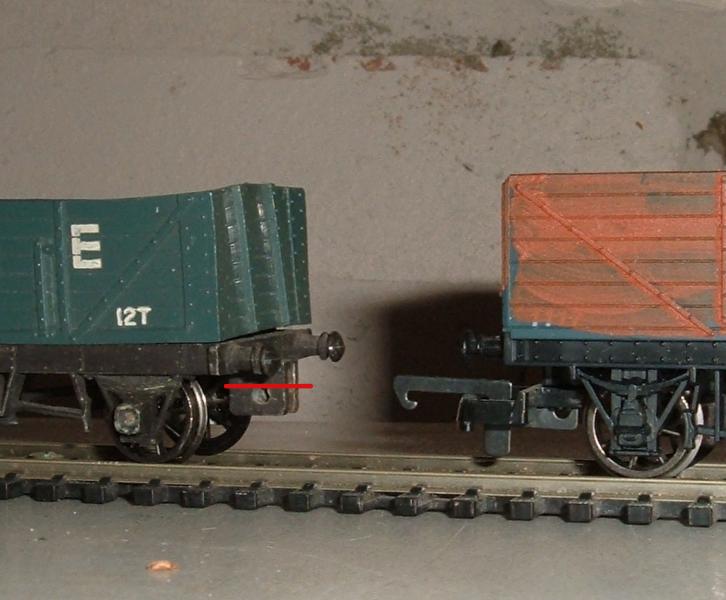

About three years ago, when I first started railway modelling again, I bought some very old Triang wagons from that internet auction site. (Probably one of a number of totally nostalgic purchases)This was before I knew about modern code 100 and code 75 track and had no inkling of things like DCC, JMRI or RR&Co. I was basically just trying to get a few bits of cheap rolling stock, to build up the amount available for the layout.

Now, considering how much theses cost I could just throw them in the bin, but ………………

Drifted out the old axles. Hornby R8098 12.6mm wheels, shouldered bearing and a bit of cyano

Plain bearings the other side and a bit of Milliput

Unfortunately since taking the picture the Milliput didn't set properly and fell out, but a drop of cyano and they're now fine.

Question is, what to do about couplings?

Probably have these as a fixed rake with a wagon at each end with a Bachmann coupling.

Wagon number two has couplings, but solid axle boxes.

Cut the axles with a hacksaw and drill out the axle boxes to 2mm maybe?

Ed

Posted

Guest user

Ian

Posted

Site staff

Ed

Posted

Full Member

Keith.

Posted

Guest user

Ian

Posted

Site staff

Agree about the way they ride Ian. Been pushing this one through the point work with the Deltic (weather permitting) and it seems to travel better than the newer all plastic offerings.

Ed

Posted

Full Member

and they definitely do run better than their modern

light-weight counterparts.

So I load them up with lead, from off-cuts of lead

flashing, that makes a big difference!

Jeff

Posted

Legacy Member

:thumbs;-):cool:

Owen

web-cam 2.2.74.174:8081

if the lights are off no cam

if the lights are off no cam

Posted

Site staff

Can't seem to cut through the axles on the brown wagon at the moment. I had a bit of a go with a hacksaw, but it's been so cold in the garage I've had to give up.

Ed

Last edit: by Ed

Last edit: by Ed

Posted

Full Member

Jeff

Posted

Site staff

(Guess what's on my Christmas list

)

)Ed

Posted

Banned

Cheers, Gary.

Posted

Site staff

The brown wagon's old style T/L is the right height and I'll probably leave on, but if you look back at the blue wagon it's just got two bits of mazac protruding from the chassis, where the old T/L style coupling was riveted on.

I'm thinking of maybe just using the hook from a T/L, in some way connected using the hole where the rivet was.

Since we've actually got some sunshine today I'll try and take a couple of pictures later, which may explain a bit better.

Ed

Posted

Banned

Cheers, Gary.

Posted

Site staff

Posted

Site staff

I could cut the mazac as indicated by the red line, but it may then be difficult to attach a Bachmann coupling to what's left.

Alternatively, put some sort of rod through the hole where the rivet was and attach just the hook from a T/L coupling.

(yes, I know the body is not quite on the chassis

or, just a loop of wire for a T/L hook to attach to.

Other end with the old Triang T/L on the brown wagon.

Just thought someone else might already have done something like this.

Ed

Posted

Banned

Cheers, Gary.

Posted

Legacy Member

:thumbs;-):cool:

OWEN

web-cam 2.2.74.174:8081

if the lights are off no cam

if the lights are off no cam

Posted

Full Member

Yes, I just cut the Mazak off, filed it flat then used the 'Draft gear boxes' with Kadee No 5's. With regard to weighting wagons and coaches, I bought a 3 metre x 150mm length of lead roof flashing which is easily cut into suitable sized strips as required and incorporated into wagons wherever I can fit as low down as possible to keep the centre of gravity low.

Keith.

Posted

Full Member

For weight, I've sometimes used lead weights used for fishing lines (or even 12 or 16 bore shotgun shot) pushed into BlueTack or plasticine worked into the gaps in the chassis frames - depends how much extra weight you need ……….I'd have thought with a diecast chassis, you won't need that much. :hmm

'Petermac

1 guest and 0 members have just viewed this.