Kevin's Inglenook Junction

Posted

Full Member

Two Planks Become One

Hi Nigel. I was unable to answer your question because I am sorry to say “ That I have never been able to understand C/ V’s “. If it was or is a matter of just connecting my direct current controller to the track, it would be “ simples “. I had considered the pickups? but when it was running okay it just stopped and hasn’t worked since, bearing in mind that I always disconnect everything and put any Loco back in its box even the Pug ( that hasn’t been converted to DCC, I cannot see how it could be the pickups. Both of my sound jobs were on Bachmann Locos ie the. 08 Shunter and the ex GWR 57xx Pannier read “ Manufacturer 145 “ when I tested them . But, only one of them runs.Best wishes Kevin

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Staying on the thread Kevin.

Posted

Site staff

Posted

Full Member

Staying on the thread Kevin.

Posted

Site staff

There were some compensations though

I can only reiterate what Petermac and others have said mate, Sort out a short piece of track for a program track,

Nothing fancy, just a plain piece of track with a method to alow you to connect the powercab. It eliminates ANY chance of the wiring on the various inglenooks, fiddly yards or what have you, being the problem, and allows you to check if the powercab is talking to a DCC chip. Now home again so I need food, beer, sleep

Cheers

Matt

Wasnie me, a big boy did it and ran away

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

"Why did you volunteer ? I didn't Sir, the other three stepped backwards"

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

He pointed out a dip in the track at the baseboard joint, now I have levelled that and everything is okay?

But a new visitor to Inglenook Junction, a Heljan Class 33 has had a couple of slow runs to and fro on DC before getting its new Decoder, and at the very graceful pace located a Bump between Peco Code 75 flextrack and the Peco Code 75 point, could it be the “ fish plate�. I have had this problem before, and no, the fishplates are fitted correctly., I put it down to the Insulated fishplate. A solution has been suggested, when the track has been tested and fixed down using a 20mm piece of Plasticard ? in lieu of the insulation, remove that and fill the gap with Miliput ( sounds a bit messy to me). Best wishes Kevin

Staying on the thread Kevin.

Posted

Site staff

Has any other loco running over the joint found a bump, if you run your finger along the rail over the joint can you feel a bump?

Ed

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

Presumably you are using Code 75 fishplates and not Code 100 …………………..

'Petermac

Posted

Full Member

Staying on the thread Kevin.

Posted

Site staff

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

Staying on the thread Kevin.

Posted

Site staff

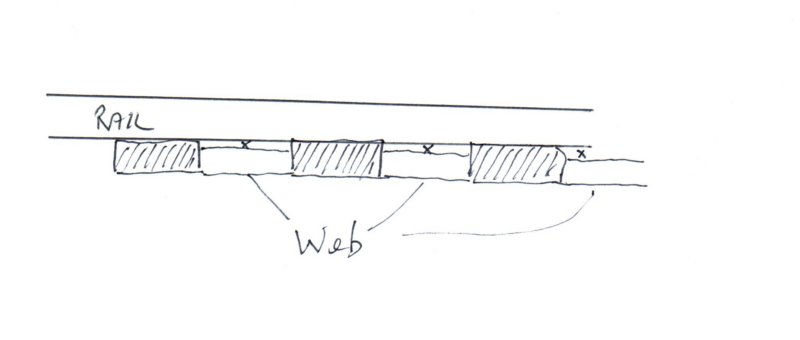

the little x's is the gap that allows the metal fishplate to sit under but using the insulated versions which are thicker, causes a bump.

So one has to remove the webbing, If you want to put a sleeper back to fill the gap, you have to thin it down where it sits under the rail to accommodate the insulated joiner.

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

Staying on the thread Kevin.

Posted

Legacy Member

I suggest you put on a head magnifier or some sort of magnifying glass and look closely at where you have used the joiners looking at both rails looking inside and outside of the rail you will probably find is where you problem is.

Brian

OO gauge DCC ECOS Itrain 4 computer control system

Posted

Full Member

Staying on the thread Kevin.

Posted

Full Member

I did notice a.lot of emails which I will reply to when I can cut my finger nails, this reply has taken me an age.

Best wishes Kevin

Staying on the thread Kevin.

Posted

Full Member

Michael

1 guest and 0 members have just viewed this.