NotMutley - take 2

Posted

Full Member

Freelance 00 layout

Thanks Colin - I will give that a go.

Posted

Full Member

I have a Portescap motor which I believe is coreless? it works perfectly with DCC, CV#10 is not turned off?Checking my DCC install notes on the Dean, I turned off Back EMF viz. CV#10 =0; essential because it is a coreless motor.

I have a vague recollection that the CV number to control this function may be chip dependent. I'm using an old style DCC Concepts Zeno Nano.

Phil

Posted

Full Member

I admit I'm no expert on this topic. However, AFAIR both the Dean Goods and the DJM Class 4800 both suffered from bad slow running and that turning off BEMF was the recommended solution for their coreless motors. This does not mean it need apply for every coreless motor.[user=2170]Colin W[/user] wrote:I have a Portescap motor which I believe is coreless? it works perfectly with DCC, CV#10 is not turned off?Checking my DCC install notes on the Dean, I turned off Back EMF viz. CV#10 =0; essential because it is a coreless motor.

I have a vague recollection that the CV number to control this function may be chip dependent. I'm using an old style DCC Concepts Zeno Nano.

I suggest that David might search back thru the RMweb topic on the Dean Goods which I mentioned for references to BEMF and CV. I'm confident that'll turn up something relevant for him

Posted

Full Member

To make room for the Stay Alive ;-)Very sorry to hear about the Dean Goods, you are not alone. This model has had a long history of issues and there are 86 pages on it over on RMWeb and misc. reports on here.

. Not sure why hard wiring the DCC would help though.

Its also a not unreasonable precaution in a loco prone to shorts.

The first release of the Dean, in the ornate lined livery, had twin flywheels. There was such an out cry about some of the external design flaws that some of them were corrected in subsequent releases- which must have been expensive- coincidentally one of the the fly wheels was removed! :twisted:

Posted

Full Member

To make room for the Stay Alive

And the motor downgraded!Its also a not unreasonable precaution in a loco prone to shorts.

The first release of the Dean, in the ornate lined livery, had twin flywheels. There was such an out cry about some of the external design flaws that some of them were corrected in subsequent releases- which must have been expensive- coincidentally one of the the fly wheels was removed! :twisted:

Meanwhile……

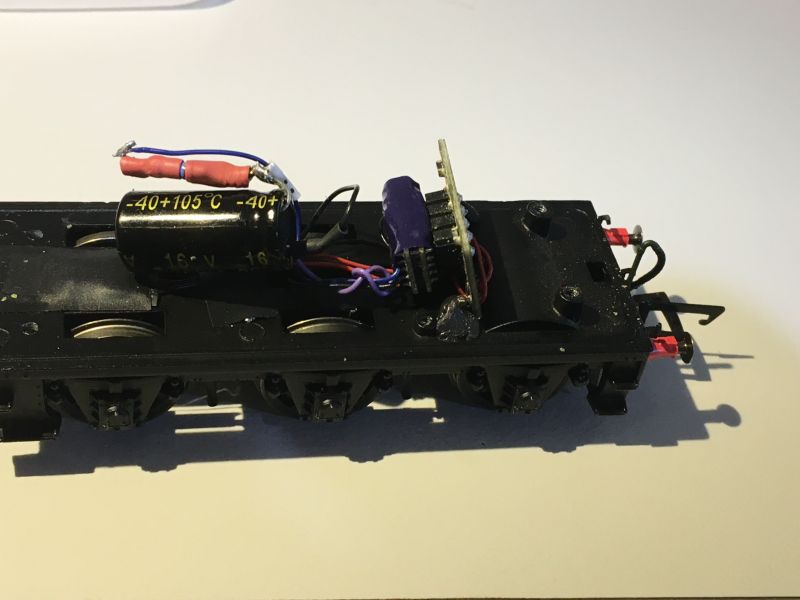

You'll see why I was puzzled! I had plenty of room, once the Sound chip and speaker came out, to fit a standard cap which is all I found necessary. Then the Zeno Nano is tiny and a direct plug in anyway. I have surplus since shifting several locos over to sound.

One other consideration with older ESU chips which I've heard mentioned is they need to be connected to a Stay alive via a proprietary ESU device. Something I've no personal experience of but worth checking up before doing!

With the DCC Concepts Chips I build my own power management, they describe the simple circuit on their website. It can be seen alongside the Cap (with some primitive soldering it appears!) but it works.

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

Here is an update!

So far I have cleaned all the wheels and adjusted the back to back on the wheels - the wheels on the tender were way out and getting the correct separation has helped but only mildly improved performance.

I am working my way through the commentary on RM Web - in my case it does not appear to be the pickups as slow running in DC is not a problem only in DCC. I have tried a few different decoders but all produce the same result - smooth running at high and medium speed but inconsistent running at slow speed!

I even tried removing the micro capacitor.

I even tried removing the micro capacitor. I'm thinking maybe I should put the Dean back in its box and focus on a different loco before I loose my mojo

Posted

Full Member

So, no good news so far but given you have a choice of decoders available, have you tried one where you can turn off Back EMF?Thank you for your suggestions.

Here is an update!

So far I have cleaned all the wheels and adjusted the back to back on the wheels - the wheels on the tender were way out and getting the correct separation has helped but only mildly improved performance.

I am working my way through the commentary on RM Web - in my case it does not appear to be the pickups as slow running in DC is not a problem only in DCC. I have tried a few different decoders but all produce the same result - smooth running at high and medium speed but inconsistent running at slow speed!I even tried removing the micro capacitor.

I'm thinking maybe I should put the Dean back in its box and focus on a different loco before I loose my mojo

The default tends to be "ON" at least up to some certain intermediate speed point. I even had a trusty Bachmann 45xx Prairie where adjusting BEMF helped with smooth slow running so it's not just some coreless motors where this may help.

Posted

Full Member

Another update.

I decided to go for broke and removed the DCC plug, the body and the pick ups on both the loco and the tender. Cleaned everything ( there was lubricant all over the pickups in the loco). Then I reassembled checking for continuity in the wiring as I went along. The loco ran fine in DC - even at low volts it crawled nicely.

Rewired the DCC plug ( Oxford Rail have all the connections clearly labelled so that was straight forward. ) Reset the decoder to factory settings and then reprogrammed. Setting the BEMF to off.

My expectations were high but whilst the loco ran more smoothly but not like it had in DC.- the motion was still jerky at low speeds.

I switched the decoder for a Lenz Silver but the result was the same

. So now I am thinking it must be the decoders which are all "new" but at least six years old - maybe they don't like the cordless motor? (That said I bought an Oxford Rail Janus 0-6-0 at the same time I bought the Dean and it also has a cordless motor and runs fine.)

. So now I am thinking it must be the decoders which are all "new" but at least six years old - maybe they don't like the cordless motor? (That said I bought an Oxford Rail Janus 0-6-0 at the same time I bought the Dean and it also has a cordless motor and runs fine.) In case you are wondering why I bought the Janus the answer is I'm not sure - as I am at a stage where I should be reducing the fleet of locos not buying more!!!

So what do I do next? Before I lost my mojo the first time (shortly after this post in 2018) I went and bought 20 ESU decoders to replace older decoders and to have consistency in performance across the fleet, and to make profiling in Train Controller easier. Do I buy a new decoder just for this loco or do I park it in the engine shed and let it do quick sprints around the layout every now and then?

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

Are all coreless motors the same?

Last edit: by Phil.c

Last edit: by Phil.c

Phil

Posted

Full Member

Good running models of Second Generation releases of the Dean Goods ( the one with a coreless motor and one flywheel) do exist that operate under slow running conditions and DCC control.

I've had mine running with both its original Loksound V4.0 by ESU as purchased and later with a DCC Concepts Zen Nano. I did not need to turn off BEMF to achieve this good running but did anyway. Others lucky enough to get a good one seem to have had no issues with using DCC, reported here and on RMWeb topic.

Coreless is a motor design type covering many variations as per Cored motors. Hence it's most unlikely all have the same characteristics. This site provided some helpful info of the differences and merits of Cored vs Coreless motors.

https://www.progressiveautomations.com/blogs/products/cored-vs-coreless-dc-motors-which-should-you-choose

For the problem in hand, now having tried two types of DCC chip, isn't it now most likely that it is the motor at fault when run under DCC since all is OK for you on DC?

There is strong precedent for this from all the multiple failures which I and other modellers have experienced.

Maybe the answer is to re-motor the loco since you can't expect a replacement. I'm almost certain I read of one brave soul who reported this on the RMWeb topic. I don't see trying more and more DCC chips as the answer at this stage.

Posted

Full Member

I am sorry to hear that you are still having problems with the Dean.

The fact that it behaves ok with DC is significant. Have you considered doing a factory re-set with one of the decoders and then entering the key CV values?

If its any help here is the profile of the Dean I use for quite complex automated shunting.

Zimo MX617 hard wired with 6700 uF Supercap

CV:

2 : 1 3: 1 4: 1 5: 90 6: 54 57: 125 *

* Average DCC voltage on Granby 12.5

I have no connection with Zimo or the supplier Youchoos but I think their decoders are superb. I used to swear by Lenz but in the last 3 years I have been progressively switching over to Zimo plus Stay Alive. Virtually all my tank engines now have Zimo decoders and Youchoos SA- amazingly reliable and super smooth.

It might be worth a try before attempting to change the motor.

Best wishes

Posted

Full Member

His Granby routines would be at the extreme end of demanding and so if anyone should know…. but if there's another failure with a trusty Zimo following his formula that would be three strikes.

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

The Dean Goods 2475 GWR unlined is a later model I think as it only has one fly wheel. In my searches on the web I noted that Oxford Rail have a five pole motor in their sound version.

I have decided to follow John's lead and order a ZIMO decoder and see how that goes. If it comes to no good I will have another decoder to add to my collection.

As an aside swapping decoders with other locos that haven't run for a long time has meant I have spent a lot of time looking at some of my locos that I purchased years ago and that haven't been run in ages. I quickly was given a reminder that the wheels on Heljan diesels tarnish very easily and need a lot of cleaning !!!

The decoder will take a while to come from the UK so it may be a while before I can let you know how it worked out. ( since COVID the local and overseas mail service has deteriorated substantially - local mail that used to take 2-3 days can now take 6-7 days and overseas mail from the UK took a month last time I ordered something.)

Posted

Full Member

Sound or no sound, there is no relationship at all to motor type for the OR Dean Goods releases. From the look of it, your link is to very old info from OR on the Gen 1 release no 2309.Thanks once again guys.

The Dean Goods 2475 GWR unlined is a later model I think as it only has one fly wheel. In my searches on the web I noted that Oxford Rail have a five pole motor in their sound version.

Both 1st and 2nd Gen types were released with and without sound. My 2nd Gen 2475 GWR unlined was bought with sound and hence the coreless motor + one flywheel.

IIRC Oxford Rail were quite lax with their model info on the later releases, continuing to say the loco had a 5 pole (hence Cored) motor when in fact it had been switched over to Coreless. In fact I had communication directly with one of their senior reps regarding my sound chip failure and he seemed not to be aware of the switch in motor type.

Someone in the RMWeb topic pulled a motor (probably a dud) apart to show definitively it was coreless, finally ending any confusion regarding the facts.

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

The loco runs more smoothly and is not as stop start as before. I will get out my ESU programmer and connect it to my PC and programming track and see if I can work out what is going on !

Posted

Full Member

Thanks Colin, I will keep persevering!! - its a lovely model, if only I wasn't using DCC !! :roll: :roll:[user=540]gdaysydney[/user] wrote:Sound or no sound, there is no relationship at all to motor type for the OR Dean Goods releases. From the look of it, your link is to very old info from OR on the Gen 1 release no 2309.Thanks once again guys.

The Dean Goods 2475 GWR unlined is a later model I think as it only has one fly wheel. In my searches on the web I noted that Oxford Rail have a five pole motor in their sound version.

Both 1st and 2nd Gen types were released with and without sound. My 2nd Gen 2475 GWR unlined was bought with sound and hence the coreless motor + one flywheel.

IIRC Oxford Rail were quite lax with their model info on the later releases, continuing to say the loco had a 5 pole (hence Cored) motor when in fact it had been switched over to Coreless. In fact I had communication directly with one of their senior reps regarding my sound chip failure and he seemed not to be aware of the switch in motor type.

Someone in the RMWeb topic pulled a motor (probably a dud) apart to show definitively it was coreless, finally ending any confusion regarding the facts.

Posted

Full Member

Under the standards set for DCC CVs by the NRMA, some are Mandatory and others free for individual Manufacturers to use as required.It is definitely decoder related as the performance has improved since I put in some of John's CV values. Interestingly the CV5 value of 64 is the maximum value the decoder will accept and there is no CV 57 !.

The loco runs more smoothly and is not as stop start as before. I will get out my ESU programmer and connect it to my PC and programming track and see if I can work out what is going on !

Even the widely used CV5 can vary by manufacturer (something I'd not realised).

The significance of this with your issues is that you must work with CV definitions relevant for your specific chip(s).

CV values for another brand may or may not work for you and you risk further confusion unless you keep this well in mind. Your discovery about the missing CV57 is a point in case (it's not used by ESU AFAIK).

Do searches for ESU v4 (or your version); CV; slow running; etc. I easily turned up items which may be helpful in your mission.

Usually you'll not be the first to face a problem and just need to find the relevant solution on line.

Posted

Full Member

A lot of fiddling and I managed to fine tune the decoder changing the values of CV 53, 54 and 55 with BEMF on ( the loco ran poorly with BEMF off ) so that the loco ran smoothly at all speeds but the motor was humming. So I have decided its time to place an order for a Zimo decoder. John from Youchoos was very helpful.

Watch this space!

Posted

Full Member

I then turned my attention to the Dapol Class 22 which I purchased 10 years ago. After reading the dapol maintenance instructions I looked at the bogies and with screwdriver in hand attempted to remove the base plates of each bogie to get to the gears. They are much like the heljan ones in that they clip on - but these just refused to budge and given the alternative of damaging them and trying to get replacement parts or leaving them I decided on the later course. I have searched the internet looking for clues as to the secret in getting the clips off but no luck.

If there are any club members that have successfully managed to remove the cover over the gears I would love to hear from them.

Posted

Full Member

Just read the thread. Runs OK on DC, not so good (jerky?) on DCC. Swapping decoders and playing around with CVs still gives jerky progress. This quite a common problem apparently (lack of QC and QA by Oxford and a lot of others in not making sure the decoder is optimized for the motor).

What is the DC system you are using? Most DC controllers output at low power is fairly smooth PWM (unless it's a cheap and nasty one), just like DCC, except the peaks tend to be a lot smoother than DCC (which is straight up/down). Coreless motors have a lot less torque than cored ones, and unless it's a decent one ($$$ as opposed to $ for cheap ones) will tend to chatter at low speed unless well designed (smooth low speed and coreless is probably an oxymoron). The same as DC motors, you get what you (or Oxford) paid for. The other thingto keep in mind is that coreless motors were designed for pure DC, not DCC.

Looks like you will need to play around a long time with a bunch of CVs to get it smoothed out (CV 2, 10, 209, 210, 212, 213 and 214) and switch BEMF off. ESU and Zimo decoders are supposed to automatically come up with the best combination for coreless motors.

The other thing to keep in mind is that DC benefits a bit from those RF capacitors, DCC usually doesn't, especially with BEFM on. I usually get rid of them.

Nigel

©Nigel C. Phillips

1 guest and 0 members have just viewed this.