NotMutley - take 2

Posted

Full Member

Freelance 00 layout

Hi Dave,My small layout has been a great help to get me through all the lockdowns here in Victoria. Nice to give your mind and attention to a COVID-19 free world!

Cheers,

Claus

www.flickr.com/photos/ellef/

Claus

www.flickr.com/photos/ellef/

Posted

Full Member

[user=1886]DaveH_Murcia[/user] wrote:Hi Dave,RR & Co. True at the rate some of us seem to be moving we will have forgotten most of what we leaned. Hopefully it's like riding a bike and it all comes flooding back. Maybe a bit of "running trains therapy" would be go for us all once in a while.

I did as John and you suggested and climbed over the mess on the floor, cleaned the track and ran some trains around the circuit for a while.

I then switched on the computer and fired up TC to try and recall how it all worked. It didn't take me long to realise how the old computer powering TC is getting but … it made me recall one of the things that had resulted in my mojo leaving home!

The layout is poorly designed in that trains running anti clockwise have plenty of routes that they can travel on but trains traveling clockwise are fairly limited unless they travel the wrong way on the down line.

So today I found my mojo and have started taking up track and will put in a few more points to give the layout (and TC) some more flexibility. I spent this afternoon rummaging through the many of boxes of "stuff" and found all the parts I need ( including the electronics) to set up the point and add a block or two.

As I will be making more mess the tidying up can wait a while longer !

Excellent!

I have a similar problem which forced me to go for more out and back routines.

Did all the TC routines come flooding back? I was only away for a few months and it took me while to remember some quite elementary procedures:oops:

What version of TC are you using?

Best wishes

Posted

Full Member

Hi John,Excellent!

I have a similar problem which forced me to go for more out and back routines.

Did all the TC routines come flooding back? I was only away for a few months and it took me while to remember some quite elementary procedures:oops:

What version of TC are you using?

Best wishes

In a word "nope" I even struggled to find my way around the program especially when I tried to change the grid size! :oops: Its going to be a steep learning curve!!!

I'm using version 9.0.B1 - I have just seen that the latest version is B3 but I cant find anything regarding the updates so I'm not sure I'll bother unless you recommend it -

I found this on the TC website -

"In the past, there were always countless user problem reports after every update.

For example, there were users who changed a setting during or shortly after the update, and when problems arose from this they thought that this could only have resulted from the update.

Other users had not saved their project files in the recommended locations. After these files were no longer automatically found by the software after an update, these users said that the update had deleted their files. etc. etc.

We conclude that updates bring more problems than benefits for many users. We are therefore very reluctant to inform existing users about new updates."

Herr Freiwald has some weird ideas about keeping his customers satisfied - these users are such a nuisance!! :shock:

Cheers Dave

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

Hi Dave[user=434]John Dew[/user] wrote:Hi John,Excellent!

I have a similar problem which forced me to go for more out and back routines.

Did all the TC routines come flooding back? I was only away for a few months and it took me while to remember some quite elementary procedures:oops:

What version of TC are you using?

Best wishes

In a word "nope" I even struggled to find my way around the program especially when I tried to change the grid size! :oops: Its going to be a steep learning curve!!!

I'm using version 9.0.B1 - I have just seen that the latest version is B3 but I cant find anything regarding the updates so I'm not sure I'll bother unless you recommend it -

Cheers Dave

I had exactly the same experience…..you will be surprised how quickly it comes back to you.

I have been using B3 since its announcement (February ?) with no bugs. I can see no reason why you shouldnt use it. If memory serves B1 had an issue with the orientation of train sets and that seems to have disappeared now

Cheers

Posted

Full Member

Hi John,Hi Dave

I had exactly the same experience…..you will be surprised how quickly it comes back to you.

I have been using B3 since its announcement (February ?) with no bugs. I can see no reason why you shouldnt use it. If memory serves B1 had an issue with the orientation of train sets and that seems to have disappeared now

Cheers

I've downloaded and installed the latest version of TC and its running fine.

I've also modified the layout to give me more flexibility and prototypical running ( no more running a train down the up line! - or is it up the up line? ) .

I'm slowly relearning the tricks of TC and have reverted back to your tutorials - which brings back memories when we worked together with Max get his layout automated. - I had forgotten how long ago that was…

Now I have a question that you may be able to answer and save me hours of reading and experimenting -

I now have easy access and exit to the engine yard ( which I never wrote schedules for due to issue above)

How, do you program TC to store multiple locos ( manly panniers) in the one block?

I want to be able to run engines light into the yard in any order and then for the computer to be able to maneuver them as necessary - say there are three locos in the siding I want to program TC so that it moves the loco nearest to the points into another siding to allow the next loco to perform its duties.

I guess I first need to recall how to get TC to run three locos into a single block.

I went back through the RR&Co forum and found the old files when Max was setting up his box cars Boxcars - that was a good starting point.

However, the fog of time hasn't lifted yet - in particular using virtual contacts.I

In the instance above can I include the contact as one section and use the two virtual contacts for two other trains making three trains in all? Or do I use three virtual contacts and ignore the actual contact? :shock: I have spent about

four hours trying a few combos but without success.

Any assistance would be appreciated.

Dave

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

Hi DaveHi John,

I've downloaded and installed the latest version of TC and its running fine.

I've also modified the layout to give me more flexibility and prototypical running ( no more running a train down the up line! - or is it up the up line? ) .

I'm slowly relearning the tricks of TC and have reverted back to your tutorials - which brings back memories when we worked together with Max get his layout automated. - I had forgotten how long ago that was…

Now I have a question that you may be able to answer and save me hours of reading and experimenting -

I now have easy access and exit to the engine yard ( which I never wrote schedules for due to issue above)

How, do you program TC to store multiple locos ( manly panniers) in the one block?

I want to be able to run engines light into the yard in any order and then for the computer to be able to maneuver them as necessary - say there are three locos in the siding I want to program TC so that it moves the loco nearest to the points into another siding to allow the next loco to perform its duties.

I guess I first need to recall how to get TC to run three locos into a single block.

I went back through the RR&Co forum and found the old files when Max was setting up his box cars Boxcars - that was a good starting point.

However, the fog of time hasn't lifted yet - in particular using virtual contacts.I

In the instance above can I include the contact as one section and use the two virtual contacts for two other trains making three trains in all? Or do I use three virtual contacts and ignore the actual contact? :shock: I have spent about

four hours trying a few combos but without success.

Any assistance would be appreciated.

Dave

That all sounds very promising. The tutorials are a bit past their sell by date but I am delighted to try and help.

I dont use virtual contacts now, they are a bit of a legacy option, I use flagman indicators in their place. The flagman is triggered by the contact indicator turning off in the entry block (BE) that immediately precedes the storage block (BS ie when the the loco exits BE and enters BS.

The rules of the schedule(s) that initiate this movement needed to be amended…..check these boxes:

Occupied Blocks and Routes Enter occupied blocks

Reserve occupied blocks

Train Sets/Join in Destination Block Enter reserved destination block for joining

You will finish up in BS with the 3 locos in a single train set. The exit schedules that moves them out, one at a time, must contain [Separate rightmost loco] in the entry commands

There are a number of ways of ensuring that only one set of brake/stop markers is activated but before I suggest them could you tell me:

Does the storage block not have a contact indicator?

When the first loco exits BS do the remaining 2 locos need to shuffle up within the block so that a new loco can enter BS bringing the total back to 3? Its much easier if the answer is no but it can be done if needed

Could you upload a screen shot containing:

The immediate entry block (s?)….storage block……the immediate exit block (s?)

More questions than answers

……but no worries it can be done

……but no worries it can be doneCheers

Posted

Full Member

I have made a separate file so that I can experiment and have now placed 3 flagmen in the Storage block BS (Block 5)

.

.The schedule works for the first loco but it stops at the first flag.

I then found this in the "bible" - I'll let you know how I get on…..

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

So is the plan LIFO? It is still possible to extract a loco other than the last one from B5 by temporarily moving the blocking locos into one or other of the two blocks not used by the outgoing schedule.

You are correct we need to add conditions.

With the flagmen embedded in the blocks I would create 3 associatd on/off switches (P1, P2, P3) which you can position above block 5 so you always have a visual indicator. The switches will be turned on by the flagman and used as conditions.

They would be turned off by a start command in the schedule that moves the loco out of block 5

I would set the memory of each flagmen to 60 seconds with auto reset checked…..you just want them to have time to activate the stop markers

The schedules for blocks 1-3 should have a condition P3 off……block 5 is not full

Flagman 1 Condition P 1 off

F2. P1 on and P2 off

F3. P1 on. P2 on. P3 off

Thus only one flagman will be triggered and only one set of brake/stop markers activated

It might appear over complicated but its how I would approach it

HTH

Posted

Full Member

Before setting up the flagmen as per your suggestion I thought I would give the "line up" a try.

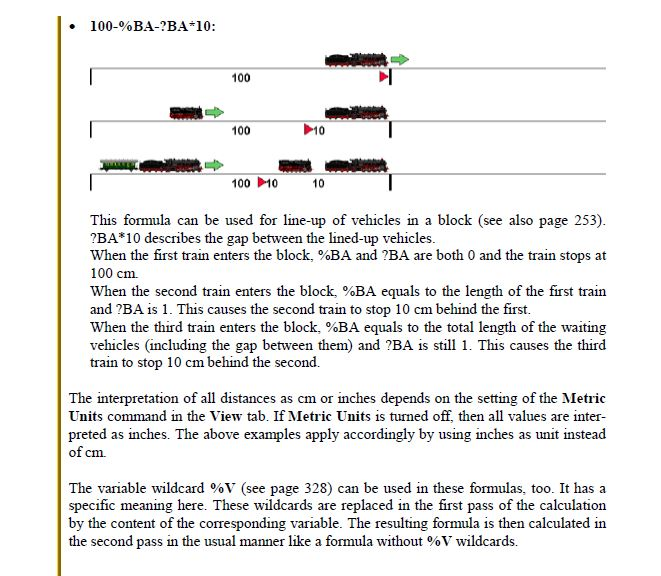

To my surprise ,I have found that with the "line up" function in the schedule and the formula in the storage block I have been able to get TC to determine how many locos will fit in the block (75-%BA-?BA*10 ) This will give me the flexibility of storing say two large locos or 4 small ones. ( Isay "surprise" as in the past I have found the instructions in the manual a tad light on)

Took me a while to work out why it wasn't working initially - the user guide shows the formula as 75-%BA-?BA*10: :shock: the colon turns out not to be part of the formula!

This is how the storage block looks now:

75 being the length of the track and 10cm being the distance between each loco/train.

Apparently the locos move up automatically after a train/loco has exited the block to the right. As my block is not a through road running a schedule that ends in the Storage Block with the "Start Reverse" command will run the first train into the starting block of the schedule. Hence the order of the locos in the block can easily be rearranged.

The changes to the schedule where minimal -

Now all I have to do is to ensure my decoders are programmed correctly !!

Dave

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

I am sorry I should have mentioned the lineup function earlier as a possible solution :oops:

I tried it initially but found that you cant adjust the loco speed when moving up within the block. You have to use the speed set up when profiling. I found my start up speeds were too slow for this exercise so I discovered a different method to move a loco within a block.

I am delighted you have got it to work satisfactorily

Posted

Full Member

So far all my focus has been on programming using the small file I built to test and learn. Now I have to build it in into the Notmutley switchboard and test it with real locos.

Watching the simulation I got the impression that the arriving locos move into the block as far as they can thus avoiding any moving up. Hopefully that will be the case. As I am not using it as a "through block" the trains/engines should not have to shuffle up as they would if the locos were exiting from the other end.

I now have to relearn the dark art of profiling locos :roll:

later……

before I got to the layout I checked the simulation and discovered that it would allow locos with a combined length greater line up block to enter the block without any warnings. I had ticked the " trains must fit into destination blocks" box - so I'm not sure its the best solution unless I have done something wrong. I have posted on RR&Co forum and I'll see what response I get

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

I see you got an answer in the RR&Co forum………did it work?

Your storage siding not being a through line changes the dynamics of the lineup option. As you say there is no need for the trains to shuffle up in the lineup when one moves out…….in fact I have a recollection that the shuffle option is not reversible; it has to be in the direction the locos entered…….it doesnt matter for you and the lineup route does provide an elegant uncomplicated way of getting three locos into one block

Cheers

Posted

Full Member

The solution was simple - pity the software doesn't mention that you needed to do that. The commentary that comes with the rule could easily include that reminder.

Now I have another problem to resolve:

With the rule working any train/loco running on a schedule to the siding, that is too long to fit because of the combined length of the locos already in the siding, now sits in the preceding block with the schedule still running.

What would be good would be to add some programming to the schedule which in this event would send the loco/train into another siding. Ideally this could be repeated until a siding with enough spare room could be found.

Currently this is wishful thinking on my part as my programming skills are only at the beginners stage :oops:

Posted

Full Member

Make the schedule to enter B5 (S5) start as an operation in the finish commands of the schedule (S4) that got the loco into B4

Make an on/off switch

In the start command of S5:

turn the switch On

In the the finish commands of S4:

Turn the switch off as a precaution

Start S5

Check if the schedule started

Prerequisite Switch On

GOTO Exit If the prerequisite is not met ie switch is off TC skipd this line and tries to start S6

Schedule 6

Schedule 7 etc

LABEL Exit

Turn the switch off .

Schedules 6 and 7 etc are from B4 to a vacant siding

In their rules do not allow the loco to stay in the start block thus if B6 is occupied S6 will fail and TC will attempt to start S7 and so on. If S6 starts S7 etc will fail.

This or something similar should work

Posted

Full Member

Hi John,II have not used the Prerequisite Goto and label command before I might need some help.Not sure if you use Prerequisites /Goto/Labels? Very useful tool

Turn the switch off as a precaution

Start S5

Check if the schedule started

Prerequisite Switch On

GOTO Exit If the prerequisite is not met ie switch is off TC skipd this line and tries to start S6

Schedule 6

Schedule 7 etc

LABEL Exit

Turn the switch off .

Schedules 6 and 7 etc are from B4 to a vacant siding

In their rules do not allow the loco to stay in the start block thus if B6 is occupied S6 will fail and TC will attempt to start S7 and so on. If S6 starts S7 etc will fail.

This or something similar should work

Just to confirm the logic - if schedule 5 runs the on /off button is switched on. If the schedule doesn't start the on/off button would stay "off"

The prerequisite command looks at the button and if in the off position it triggers the next schedule.

I built three new schedules

Sch 4 takes the loco to block 4. It turns the button to off. ( this works)

Sch 5 will run the loco into block 5 provided there is room for the loco. If there isn't, it will trigger schedule 6.

Sch 6 will take the loco from block 4 to a new block 6

When schedule 5 is triggered when block 5 is full,I get a message saying block 5 is reserved and everything comes to a halt.

This is currently the config for the start of the schedule 5

Posted

Full Member

You are almost there:

There should be a single command at the start of Schedule 5:

switch 04 ON

The command lines that you have written should be at the finish of Schedule 4 …..you just need to make two changes:

Line 1. switch 04 OFF

Line 2. Schedule 5

Line 3. Prerequisite etc

Everything from prerequisite down is perfect

Prerequisites are the equivalent of “what ifâ€

If the prerequisite is correct the next command line is executed if it fails it skips that line ( and only that line)

If schedule 5 starts the switch is turned on, the prerequisite succeeds and the command line goes direct to the exit label

If schedule 5 will not start then the switch will remain off, the prerequisite will fail and the command line will skip the goto exit and attempt to start S6

If there is a problem send me the file. *.yrrg…………I will pm my email address

Posted

Full Member

I have sent you an email.

For any members that are following this thread I have attached a file with the working solution.

John's solution gives you control over where the surplus locos/trains should go and has been a good learning exercise for me in the use of prerequisites and GoTo statements.

If you were not looking for this level of control and were happy to let the computer decide which siding the locos run into then you could simply have a schedule with multiple destination blocks. ( in the example attached the schedule 1,2,& 3 would all have blocks 5 & 6 as destination blocks )

Now back to the layout to see how it works with the physical locos - I suspect I may have to play around with their speed profiling……

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

Having the programme run as planned in simulation mode doesn't mean it will work on the layout.

The first loco into the block stops Ok - the second one just runs straight into the back of it !! :shock: and it is the same for every siding!

Back to the drawing board!

Posted

Full Member

Hi DaveProgramming wasn't meant to be easy.

Having the programme run as planned in simulation mode doesn't mean it will work on the layout.

The first loco into the block stops Ok - the second one just runs straight into the back of it !! :shock: and it is the same for every siding!

Back to the drawing board!

Not sure if you are using the identical file you sent me?

If you are there are some errors in the command sequence. I have just debugged the routine where there are two locos in block 5 and the next loco is too long……..it now goes to block 6 ok

I need to test getting a third loco of the correct length into B5

I may not be able to do this tonight but I will try and do it first thing tomorrow and send you the amended file

Just to clarify……..you cant get a second loco to stop in B5?

Do the stop and brake markers get activated for the 2nd loco?

Any clues from messages?

Next job set Sydney time up in my ipad!

Talk soon

Posted

Full Member

You havent got a flagman indicator to activate the stop markers……..the contact indicator is turned on by the first loco and remains on

I think the formula has to be attached to the flagman and the memory set to reset after say 60 seconds

1 guest and 0 members have just viewed this.