Newton Regis, it'll never be finished, hopefully!

Posted

Full Member

A GWR journey through the 1920s and 30s

Good morning Peter,Yes, you are quite right, no more cutting back chairs or removing sleepers to fit RJs to code 75 bullhead rail, but . . .

I made a Chubberesque code 100 RJ tool some 40 years ago, which is resting in a box somewhere and it worked very well. The issue for me with code 75 bullhead however, is not so much getting the joiner onto the first rail end, usually done away from the baseboard and always so when preparing points for installation, but fitting the second rail into the other end of the joiner on the baseboard. I think it may just be a case of not being able to see sufficiently well The parts really are very small and the rail needs to be precisely lined up, so I’ll use a stand magnifier today and hopefully will make better progress.

The size of the issue, it’s not a big issue, although it can be for tired peepers!

The RJ in between my finger and thumb is pretty much actual size, while the difficult to focus blow up indicates an overall width of 1mm, with a flange slot of less than 0.5mm, so definitely a challenge for most of us!

I’ll get back on the case now and hope to report on more efficient progress sometime later.

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

The rail joiner design makes for a very tight fit and they will not always slip over the rail ends easilly. Perseverance will pay off for some, hopefully many, but for the stubborn ones, I use a very small flat screwdriver blade to ever so gently ease just the end of the joiner, which helps start it on the way.

Result: joy replaces frustration!

Be safe, be happy,

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

I use head magnifiers for all my joiners and yes, you're right - it's often not the initial fitting but adding the next rail that's the problem - and I'm talking either Code 100 or Code 75 both of which are ginormous by comparison …………..

'Petermac

Posted

Full Member

There are just the 2 points in the yard to fix, then I can install some power and see if it all runs without derailment, or stock interfering with anything else. I'll also cut back the cork tile to the yard before extending the goods roads, which were usually a little lower than the running lines to protect them from runaway wagons.

The second left hand point above leads to the cattle dock and parking for the gas wagon and will be extended a little further, as will the yard roads seen below.

I’ll need a goods shed and coal trading facilities and there will be a short board extension, perhaps only 300 or 400mm long at this end to provide station and yard access. I was originally debating whether to have a third 1 200 mm long board, but decided it would make the branch too long if used as a stand alone unit, so I’m happy that the run round loop can easily handle four 57’ coaches or equivalent, plus a horse box or two.

The plan for the space to the left, which extends over a wider area on the furthest board, is actively being thought about, for an interesting and appropriate scene in keeping with my modelling period and will emerge following the usual gestation of such matters. In other words, I have an idea which may well become a plan.

Be safe and enjoy all you can,

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

I love those long smooth curves.:thumbs

Can you remind me how you are handling uncoupling?

Keep well

Posted

Full Member

I note you're thinking about developing the left of your last shot - I presume the branch serves a village/small town of some kind. A yard, to my mind, always needs some human presence and siting a village/town around it would give it purpose. You could have gently rising landform on that area which would also act as a useful backdrop. Building house terraces on a hill would seem simple but but does offer an element of "fun"…………………..

'Petermac

Posted

Full Member

Thanks John,Great progress…….you are really cracking on now

I love those long smooth curves.:thumbs

Can you remind me how you are handling uncoupling?

Keep well

I'm also a fan of smooth curves and I'm using the DG automatic uncoupling system after seeing it in action on Nick Wood's Much Murkle at a couple of exhibitions. I think(?) the mid-Cornwall layout also uses them. The activation is by fixed undertrack electromagnets and once the coupler is unlatched, the wagons can be pushed forward as with other systems for delayed uncoupling. This enables a single magnet to serve the whole yard and I have 3 magnets for the complete branch. Random uncoupling, which of course will occasionally be required, will be effected by a small magnet on a bent stick, deployed by an articulated armature under manual control!

I’m off to the railway room soon and need to determine unobstructed locations to instal the magnets under the boards. The accessory bus will be well populated, now with point motors, signals and uncoupling magnets. I can see my control panel becoming a little larger.

Be good,

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

Yes Peter, definitely needing an element of fun, so the thinking juices are still flowing, which will certainly mean some terra forming . . .You are indeed cracking on with it now Bill and, at this early "bare board" stage, the world is your oyster …………….

I note you're thinking about developing the left of your last shot - I presume the branch serves a village/small town of some kind. A yard, to my mind, always needs some human presence and siting a village/town around it would give it purpose. You could have gently rising landform on that area which would also act as a useful backdrop. Building house terraces on a hill would seem simple but but does offer an element of "fun"…………………..

:cheers

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

Terry

Posted

Full Member

I’m currently doing research regarding signalling and not altogether surprisingly, have found it to be a large and sometimes complicated subject and of course, each railway company did things in their own particular way and the technology changes also need to be charted to make sure the model is portrayed accurately for the relevant period.

I’ve a significant recent volume on GWR signalling published by the Great Western Study Group, which will eventually answer all questions and will take months to read, digest and understand. Well years probably to fully understand, so in the meantime, I’ve looked for an overview in order to establish a basic understanding and am working my way through such a work, kindly posted on another well known forum.

Prompted by Mr Dew, I accepted the challenge to install working signals, although the rodding and ground signals will be purely cosmetic. It would be nice if the motorised units from Dapol can cater for my requirements, as compromise is not something which I ever want to eagerly accept.

There is little modelling progress to report besides fitting the last two points and laying the yard roads and repainting the de-corked boards. I’ve run out of Peco’s fine track pins, so Amazon to the rescue yet again and I need to get a move on with installing point motors and track and accessory power buses, as the panel route setting gear has been despatched from the American supplier.

With the forthcoming challenges lies the excitement!

Stay well, be good,

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

Good luck with working signals - as you say, it takes a lifetime to fathom out the vagaries of railway signalling ……………….

'Petermac

Posted

Full Member

Welcome to the intricacies of GWR signalling! The GWR always prided themselves on being different …..they excelled themselves when it came to signalling.

You may have a copy already but I found CJ Freezers "Model Railway Signalling" to be a useful guide for beginners.

I am keenly aware of my limitations so I will not be attempting to make working Ratio or MSE signals. My tentative experiment with signalling the branch will be dependent on Dapol. The plan is to order and install one of their junction brackets and use it as starters for the Bay and Main Platform. If it is relatively easy to install and reliable to operate I think I can credibly signal the rest of the branch with 3 to 4 additional bracket signals and maybe a couple of fixed Distants (I can make them work with Ratio!) I hear good reports of the brackets but I am a bit wary of the single poles that were first released……..I was hoping they would upgrade them to the same standard as the brackets……but apparently not. I hope there is no time limit on the challenge…….for me Spring perhaps?

Looking forward to seeing your new control panel…..

Keep Well

Posted

Full Member

I’ve seen some magnificent modelled signals based on those intricate MSE kits Peter and can only dream of doing them justice. I do have a couple of Ratio signals built decades ago, which operate by pulling bits of string, but I'm hoping, like John, that the motorised offerings from Dapol might serve well enough.

I should have know that the indomitable Mr Freezer would have penned a tome on signalling John and I found a copy for a few pounds on Abe Books, which will be here before Christmas. Thanks for the tip off :thumbs

I seem to recall reading that the very early single pole signals from Dapol had their failures due to the wrong ratting of a simple electronic component, which had been rectified, but I must gen up on that aspect.

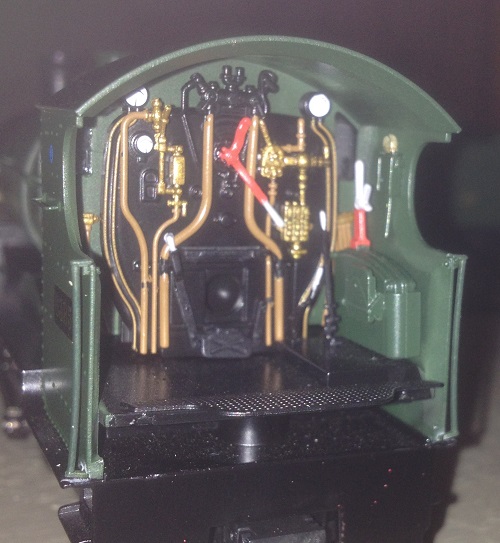

Speaking of Dapol, more smiles today in the form of a late arrival at the end of the down platform, as the parcels train deposited the following . . .

Please excuse the poor quality photos below of the new Mogul, as my ageing phone’s camera has difficulty in poor light conditions.

The cab is taken with the flash and will need some dusting to get it down to an oily rag working environment.

At least it fits the single road shed and really does look to be in full possession of the doggie dandlers and I’ll really have to get my proper camera out to capture any decent photos.

I’ve been most impressed with the Dapol GWR diesel railcars, but wasn't sure if they could do steam locos justice, but am relieved that they can. There is a 20 page booklet in the box with loco history and detailed illustrated user instructions, a large list of presumably available spare parts and the detail pack includes a set of etched number plates and even tools to open the smokebox door and a PCB extraction tool to aid decoder fitting.

The weight is good, including the tender and running in is claimed not to be required, but it will get a go on the rolling road to make sure everything works.

That’s the excitement over for today, so back to wiring and signal research.

Be safe,

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

Delighted you are pleased with your new Mogul.

We must have got near simultaneous deliveries……mine arrived about tea time.

Initial impressions are extremely favourable. The box and packaging are both robust and project an image of quality.

The model itself has some exquisite detailing…….engraved plates are a nice touch…although I am changing mine.

I just checked it on my minimal DC test track and everything worked….nice slow speed starts. Tomorrow I will put her on the rolling road. The locohas has actually arrived before the Zimo chip but I do have a Lenz Next 18 so after the rolling road I will test this new auto fitting routine

More anon!

Posted

Full Member

I really must get mine on the rolling road, but there was a diverting and unexpected delivery yesterday teatime, of the control panel components. I’ve been tidying up the trackwork, designing the temporary panel fascia and realising I’ve no dropper wire! I’ve been lazy enough to order some from Amazon, so I can continue working on the layout, rather than drive to the hardware store to buy wire!

Next is the track and accessory power buses and start fitting point motors. So much to do, great fun.

Best,

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

I’ve seen some magnificent modelled signals based on those intricate MSE kits Peter and can only dream of doing them justice. I do have a couple of Ratio signals built decades ago, which operate by pulling bits of string, but I'm hoping, like John, that the motorised offerings from Dapol might serve well enough.

Bill, I think you'll find that the original problems with Dapol single pole signals were, that they specified (incorrectly) that they should be powered by a 16v ac supply. They now instruct you to used 12v dc and I believe have also changed the motor mechanism. My slight criticism of them, apart from having two fail because of the incorrect instructions, is that the led lights are far too bright, but at least you can see them.I seem to recall reading that the very early single pole signals from Dapol had their failures due to the wrong ratting of a simple electronic component, which had been rectified, but I must gen up on that aspect.

Last edit: by pnwood

Last edit: by pnwood

Posted

Full Member

Yes, that’s it, too much juice, I remember now and I’m so happy that someone was paying attention, unlike me at the back! Many thanks for the memory jogger :thumbs

I do hope that you were satisfactorily compensated for your failed signals.

I wonder if 9 volts would still be sufficient to operate the arm and reduce lamp luminance? I feel the need for an experiment once I get mine installed.

All the best,

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

'Petermac

Posted

Full Member

Best,

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

No, not signalling, but enough DG couplers to fit 24 items of stock and absolutely no soldering will be involved. This will strictly be a morning task for me, while the eyes are not tired, as the parts are on the small side, but once a rhythm is set up, I hope they will go easily enough. More to follow as I set converting some wagons and locos for testing.

Although I’ve not done much modelling due to having to switch back to building work (our burned-out outbuilding from January is now clear of all debris, including asbestos and a temporary roof installed) I have done some soldering though, in beginning to secure the rail ends between the modules.

Apologies for poor photography, but what you see are the rail ends soldered to carefully positioned and levelled brass screws, which hold the track securely aligned between modules. I’ll tidy up the sleeper spacings and once painted, ballasted and weathered, will look much better. The good news is that a rake of stock pass smoothly between modules.

I’ll repeat the exercise for the rest of the track, then start on the electrics.

Best,

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

1 guest and 0 members have just viewed this.