N Gauge - Newcastle Emlyn****

Posted

Full Member

Posted

Full Member

Posted

Full Member

You could look at the bulldog and aluminium angle idea Marty but don't mount the angles on the top of the baseboard. As long as both bits are connected to the track electrically, they can be placed anywhere you like. Afterall, they're only there for a quick easy method of aligning the track.

'Petermac

Posted

Full Member

The "strength" of the ball catches can be adjusted, there are small grub screws to do this. However, I do agree with your derailment and Epoxy/ flexible metal concerns, they had occured to me too. Build and test I guess.

You've just given me another idea for alignment though, not sure if I can explain it, or, for that matter, build it but sort of a combination of the angle strip, bull dog clip and spring metal… (without the bulldog clip) by extending the angle strip beyond the edge of the cassette it should be possible to slot them into a locating mount on the baseboard made of another bit of angle and a spring metal.

Something else to build and test.

cheers

Posted

Full Member

Like most people I have a container full of little nuts and bolts that will never find a use!

It struck me that attaching the female part of the catch would be very easy after drilling appropriately, using a washer if necessary.

Frankly, I can't see epoxy doing the job long term.

Posted

Full Member

I'll add it to the list.

I do like this forum :lol:

edit: oh, and sorry, couldn't see the wood for the trees. :oops:

Posted

Full Member

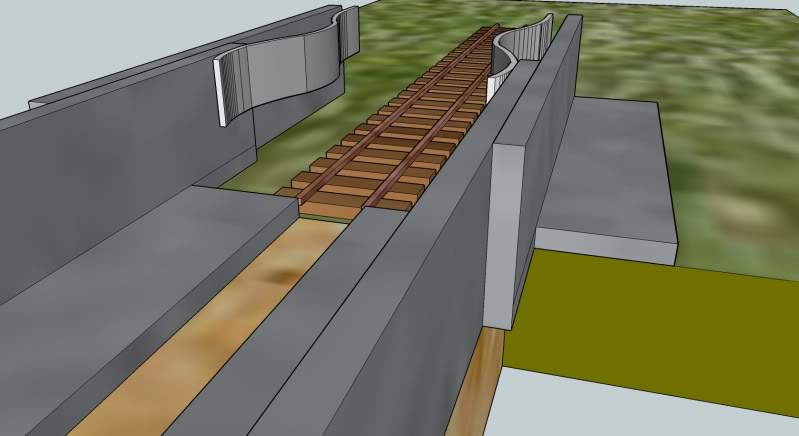

Sketch up drawing… thanks Matt for pointing out the wonders of this software.

Posted

Full Member

The similar system I saw on here used sprung wires sliding onto side plates attached to the cassette base - far less like "brute force". :roll::roll::roll:

'Petermac

Posted

Guest user

At our local club we used aluminum angle for the whole of the cassette, not just the end as the above shows.

If you don't use bulldog clips for alignment, take the word of someone with bitter experience and use small brass bolts. Its the only way to ensure accurate alignment 100% of the time. Any other method (including the one you show) will sooner or later allow mis-alignment and a de-rail.

Posted

Full Member

More grist for the mill.

Jeff, did you find any significant drop in electrical conductivity using aluminium angle? Is it worth using brass or copper angle instead?

cheers

Posted

Full Member

Just to say I've posted some more Henllan reference pics. (they are in the Gallery but I expect someone will kindly get them out and put them on the thread).

Posted

Full Member

Ixon's Manor's have finally arrived in their new form.

Cookham Manor and Frilsham Manor have been added to the stable at Newcastle Emlyn.

Here's 7816 at the head of a down special passing Pentrecourt Halt on the way to Newcastle Emlyn

Tender mounted motor powering the loco driving wheels via a cardan shaft. Detail is fantastic. Bits and bobs (including Bob and Evan) still to be added.

She motors along very nicely.

The Cardan shaft is quite noisy at the moment but should quieten with wear.

She found all the dodgy bits of my track laying, had to get the fettlers out to straighten a couple of sections and now apart from one set of points stays on the track.

Posted

Guest user

Posted

Guest user

Posted

Guest user

I Forsee a future header photo there

Brian

Posted

Full Member

Posted

Full Member

I like the first shot especially.

Doug

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

'Petermac

Posted

Full Member

(I can't wait to get back to building locos!!!)

Another header photo in the bag,Marty!

Cheers,John.B.:thumbs

Posted

Full Member

1 guest and 0 members have just viewed this.