N Gauge - Newcastle Emlyn****

Posted

Guest user

What is the panal made out of - at first, I thought it was aluminium but when I saw it "open" it looks too thick. An impressive bit of wizardry ! :wink: :wink:

Petermac

Posted

Guest user

it is finished.

Where do the names come from around the controller knobs they are obviously welsh names.

The first name in the list is actually a slang term here in the Uk for something else than a name i dont know if you knew that :lol: :lol:

cheers Brian.W

Posted

Full Member

I've never built one before so I'm hoping I haven't bitten off more than I can chew :!: :!: So far so good.

Posted

Full Member

The names are the real names of the engine drivers on the branch, I thought it more in keeping with the atmosphere I'm trying to create rather than using Cab A, Cab B, Cab C, etc for the proposed individual controllers.

There will be just two controllers to start with, just John and Fred, but 3 would easily work with the layout plan and maybe 4. The rotary switches have 6 poles and with one for off, I thought I may as well name the others.

Ben Thomas is John Thomas' son, who followed the normal path of engine cleaner, fireman and then driver.

I rather like the thought off being able to say to visitors, " You can be John Thomas tonight" :wink: :lol: :lol: :lol: :lol:

The GWR Journal article I'm using to base the layout on is a mine of information.

Posted

Full Member

Regards,John(georgejacksongenius)

Posted

Guest user

what happens if John Thomas has power on via the controller for the South Bank & Fred Jones was using Yard, left a loco sitting there & then Yard is switched to Off so passing thru John Thomas position on the rotary with power on, would not the loco in Yard now move a bit as well as any loco in South Bank? ( I have seen that happen on a layout that one of my friends had - he used that principle & quite often, locos that was supposed to be stopped, moved enough to recouple to wagons when they had just been un-coupled.)

It could get worse if all the first 4 controllers were powered up on sections & Ben Thomas decides to swich off from the Yard & having to pass 4 powered controllers to get to Off.

Is it physically possible for 5 operators to work at the same time in Henllan? If so, then this is when DCC comes into its own.

Yes under analogue, it can be wired to prevent any controller accidentally driving another loco but it does take a fair bit of switching for more than 2 operators at the same time. Perhaps the easiest way is to have rotary set up like :-

Off, John , Off, Fred, Off, Tommy, Dia, Off, Ben, Off - a 10 position rotary that would solve some problems.

Food for thought .

Posted

Full Member

The control panel isn't wired up yet, the whole Henllan layout is running off the one controller at the moment so there is room for alterations.

Sections A, B and C will be isolation switches to allow multiple engines to be stored in the Yard so as long as the loco is there the momentary passing contact of the rotary switch won't affect them.

Hmmm, it would be theoretically possible for all 5 controllers to be operating different sections of Henllan at one time… but very unlikely I would have thought.

I guess the easiest option would be to alert the drivers to the problem and ask them to check that no other movement is taking place in Henllan before switching to Off but that wouldn't stand up to the stingent safety standards of the GWR rule books so…

… having 5 controllers at once on this layout is fairly unlikely and certainly unrealistic, room for the bodies is an issue too, 3 is a squeeze in the space between the layout and the workbench.

OK, 3 is more likely so I could set up the rotary switches…

Off, John, Off, Fred, Off, Tommy.

This would still mean that changing from Tommy to John must pass through Fred… still not safe really.

An isolation switch on/off between the rotary controller and the track feed would solve the problem. Remove the off position from the Rotary Switch altogether to avoid confusion.

The procedure would be to isolate the section before changing controllers and then, once selected, reactivate the section.

Is that feasible?

Posted

Full Member

Oh good, N gauge AND GWR, I thought you sounded a nice bloke :lol:

To quote "I have a dream"… and slowly but surely I'm progessing forwards (with the occasional backwards step I must admit)

Online ordering is suprisingly good, Hattons of Liverpool are wonderful, the fastest delivery time has been 6 days. There prices are very competitive too.

My parter used to be an "Information Specialist" (Librarian) with a keen ability to locate weird and wonderful reference material from anywhere around the world and will still do so for me in return for trinkets and dinners :wink: :lol: :lol:

So overall it's not too bad, however, I've had no luck so far getting a couple more GWR Toads

Not that I've tried very hard as they won't be needed for a while yet.

Not that I've tried very hard as they won't be needed for a while yet.cheers

Posted

Guest user

How many stations are you planning & how many operators do you anticipate that will be on the layout at the same time?

Under normal circumstances, how many people will be operating?

If as you say, 3 bodies could fit in with a squeeze, could they move around easily passing each other as they drive a loco from one end to the other?

If not, then it is back to two bodies/ 2 cabs in the same operating space & that makes it electrically easy - centre off Toggles.

Putting an additional isolating switch in conjunction with each rotary takes up more space on panels & introduces another un-necesary action. I would not recommend that method.

On my previous layout, while I had 4 stations & 6 controllers, I normally had 4 people but we did not move between stations - we stayed in the same spot - no room to pass each other easily. The 2 main stations had 2 cabs each & it was possible to drive 2 trains at the same time by the one operator.

To go to the next station, I used a linking circuit which connected a common track betwen the 2 stations with a toggle switch that joined the common to say your South Bank section & the distant station operator used his toggle to connect from the same commion track to his input station track & one controller at the recieving station drove the train .

I think any control system to be used has to take into account on how the layout will be operated before attempting to finalise the control method otherwise one could keep rebuilding panels.

Hope this confuses you more. :lol:

Posted

Full Member

OK, I'll poddle off to lunch and have a think about it

… some time later…

In all that I have read about the Newcastle Emlyn Branch, and it's not a lot, I've only ever heard of two trains on the branch at the same time.

With the "addition" of the Green Grove Milk Factory and the milk tanker and van traffic to and from there I reckon that makes 3 possible trains in operation at any one time without clogging the branch up with traffic jams.

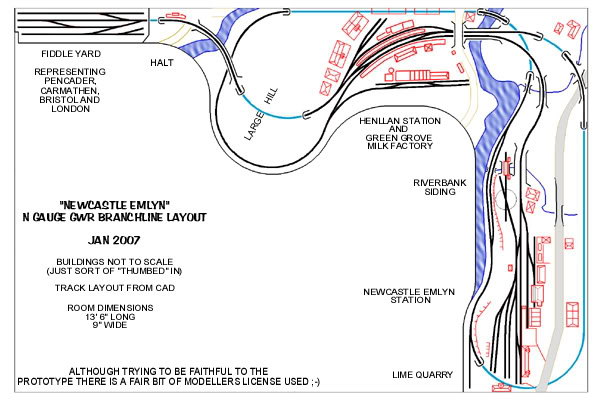

Here's the layout plan again for reference.

3 operators with walkaround throttles with 1.5m leads would be able operate the layout at once in the space around the layout but 2 would be more comfortable.

Normal operation will be one operator.

The Pencader fiddleyard is going to be replaced by a cassette system.

The plan was to have:

1) one operators control panel at the Henllan Station/Green Grove Milk Factory position and

2) one operators control panel at the Newcastle Emlyn Station/Riverbank sidings position.

At Newcastle Emlyn shunting of the yard using the engine shed road as a head shunt happended independently of passenger traffic to the station.

The original timetable calls for about 6 passenger movements per day up and down the branch and two pickup goods turns, one morning and one afternoon.

Specials include cattle/livestock trains 3 times a week, sometimes 2 or more on market day, football/fair day specials and the occasional troop train. (the 21st Artillery regiment base being nearby. AA guns mostly)

Throw in 2 milk trains per day and it gets pretty busy as far as the timetable goes.

I'll have to do a mock up to see how it will work.

Any thoughts.

Posted

Guest user

Posted

Full Member

Posted

Guest user

Working on my reply to you with a drawing as well.

Posted

Full Member

Posted

Guest user

My ideas for what they are worth;

Henllan has 2 cabs, which not only controls Henllan & the Milk Factory but also the cassette fiddle yard & Riverbank Siding together with the continuous run.

Newcastle Emlyn (NE) has 2 cabs as well.

My drawing below has the 4 cabs labelled A-D.

Suggestion is that part of the track between Henllan & NE - the bit between the two bridges be classified as the Link section - it is switchable to both stations.

The drawing has 2 toggles at each station - one is the Link toggle & the other is what selects the cab at station for that section of station trackage.

Under normal operation, each station can have 2 operators & with the cab toggles, either cab can drive trains anywhere with in the nominal station limits.

Assume a train to go from Station A to B; A sets all points & signals & cab switches to cab B then the Link toggle: now do not use Cab B at Station A.

Station B sets whatever points & signals, selects the Cab C or D for the incoming track, then the Link Toggle - this now joins Cab C or D right back to Station A to allow Station B to drive the train towards them.

In the meantime Station A using Cab A can drive another loco anywhere except where Cab B is switched to.

As soon as the train enters the Link section, Station A can restore the Link toggle to normal now removing any linking & Station A can continue on doing it likes best.

At Station B, as soon as the incoming loco has cleared the Link section, they too can restore the Link toggle.

If you are by yourself, switching all cabs to A & C at both stations plus the 2 Link toggles allows you to operate with either Cab A or C anywhere ( you could use cabs B & C or B & D - take your pick).

The main proviso is that the hand controllers have a centre-off toggle switch for direction, otherwise if Cab A is set to left & Cab C to the right, there will be a conflict of output voltage & trains may not move.

As a one-man operator going from station to station, the above works well but if you do not want to hand over to another operator when 2 or more are present, then your rotary switch plus additional isolate switch is what maybe needed. If you could obtain the gang switch like car radios had - push a button & the other in-button pops out only allowing one button at the time, this would be perfect - the drawback is the space required.

As I posted earlier, once a station has more than 2 controllers having access, it creates a lot of wiring & DCC is then ideal for this method of operation.

That is one reason why I converted, not so much the wiring & relays, etc but to make it simpler for the operators - less switches to get confused with especially at the 4 track double junction crossovers - 8 points & 4 diamonds.

If you need anymore info, you can either e-mail me at mabocat@adam.com.au or ring me on 08 8522 2536.

Posted

Full Member

I've read through twice and I think I'd better take it home and think about it some more while referring to your drawing :oops: :roll: :lol: :lol:

The concept of passing off trains to the other station operator, quite like signal boxes offering and accepting trains, is a good one.

More soon…

OK, I've just read it for a third time and I've got you and like it. I was wondering how I was going to make the "link"… as it were.

I think I'm still going to use the rotary switches since I've spent the money for them and mounted them, but in two cab mode… Cab A, off, Cab B.

Now, would you still do the same "passing control over to the next box" in DCC mode or would the operator just drive the whole way from Newcastle Emlyn to the Pencader end?

Posted

Guest user

Even under DCC, you can still pass it on but of course do not need any switching or drive it all the way as with most good DCC units, once the train has started, you can unplug the controller & move to the next station while the train is still chugging between them. I am referining to Lenz, NCE. Gaugemaster.Digitac\x type contollers - not Bachmann, ESU or Hornby console units.

On a previous layout I was involved with, we made up a train at a station, the Fat Contoller at the main console set the main links , we moved to the distant station & drove the train towards us, shunted & then we moved agin & drove it towards us again. The wiring was such that I could stay at one station & drive the train thru every station ( 9 of ) on the huge 35 x12ft - 3 level layout. This used linking principles.

Posted

Full Member

I'll keep my eyes peeled for you,mate.I attend a lot of shows over here,and 2nd hand toads come up quite regularly,so I''ll see what I can do.

Cheers, John.B.(georgejacksongenius)

Posted

Full Member

cheers

Marty

Posted

Full Member

Time for an update on progress…

Most of the work has gone on under the board wiring in the track sections and fitting point motors. Some of which are a bit sticky and will probably need tweaking. Did most of them before reading the tutorials some of you have done on the forum.

I'd like to make it clear to anyone new to installing point motors under the baseboard using the extension bar to throw the point tie bar… you really should read the tutorials and get the alignment as accurate as possible.

The control panel is on hold at the moment after discussions in the thread above while further testing and thinking goes on to determine the best way to wire up the layout for DC operations. Not a lot of thinking yet, sorry Sol, as my mind is taken up with the diorama.

The Green Grove Milk Factory sidings are now, finally, in place and being used with milk tankers, shown below, in the future loading dock

.

Cattle wagons are in the cattle loading dock in the yard on the down side of Henllan station and the Auto-coach is negotiating the cross over in the station itself.

Two types of readily available cleaning cloths have been purchased from the local supermarket and, having had their stitching cut, have been spread out to see how effective they might be as grass on the layout.

Both types will need re-colouring of course but the grass height looks OK to me and once cut up and mixed and matched should do the job nicely.

The yellow version is a home brand and the individual bristles are shedding like leaves before a storm. Some experimentation is required to see how they can best be used. Either painted and sprayed with hairspray/fixative or used like medical lint, glued to the scenery and the backing ripped off.

The Pentrecourt Halt diorama is now in full production and can be found in the diorama section.

Until the Halt is completed, work on the layout itself will take a back seat. It won't stop altogether but the diorama will be used to trial some scenic modeling skills that I have never used.

Next on the layout is the line from Henllan to Pencader via the Halt (a mark two version once the diorama is completed), mainly because the Henllan station yard throat as it currently is doesn't provide enough room to shunt properly.

The other layout task high on the list is to complete the Henllan control panel, including the point levers so that I can do the shunting sitting down. Uncoupling still has to be done manually but at least changing points will be done without getting off the stool all the time.

Number One Son dropped by out of the blue last Sunday afternoon, I tasked him to shunt the local goods from the main line into the yard and the milk tanks from the goods into the factory siding.

Couldn't get him off. Once shunted as directed, the train was re-assembled in the yard loop, the engine re-attached and with a cheery wave he set off for Riverbank sidings.

That's my boy.

1 guest and 0 members have just viewed this.