N Gauge - Newcastle Emlyn****

Posted

Full Member

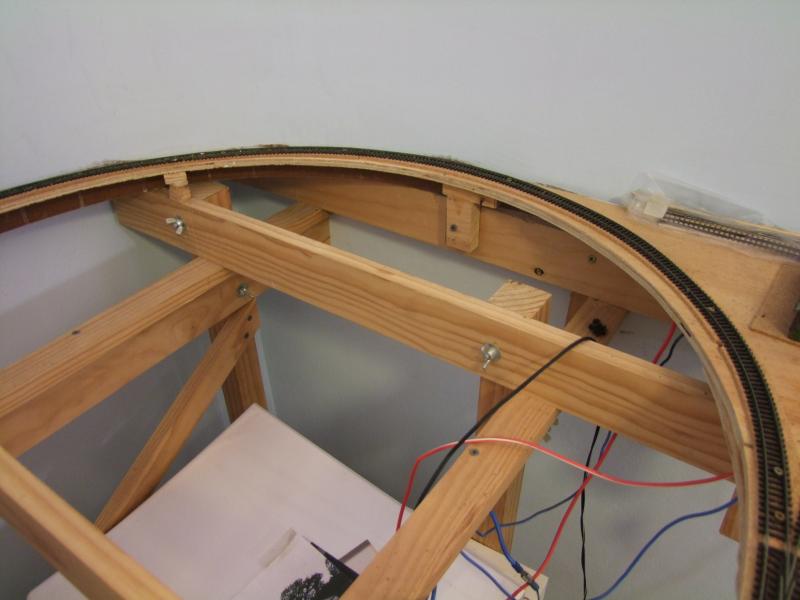

Gave myself a half day holiday on Friday and managed to get a bit more done on the layout.

Now that the dodgy bit of track has been fixed on the corner it was time to put up a retaining wall of some kind to complete the process of making it safe for stock to negotiate.

Originally it looked like this….

Now, with the use of a bit of recycled slat blind (knew it had been squirreled away for a reason) it now looks like this…

Trains can now whizz by with safety…. fall off THAT you B******.

Onwards…. I think that some track planning in Anyrail is next….

cheers

Marty

Posted

Inactive Member

Good thinking with that redundent blind panel.

Cheers,

Derek.

Posted

Site staff

Ed

Posted

Full Member

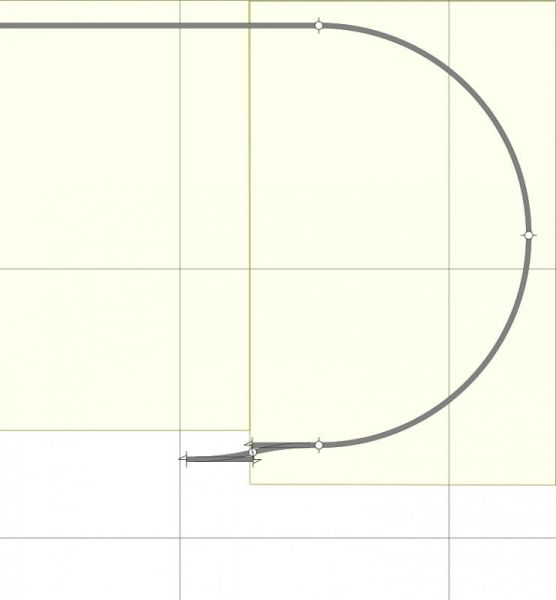

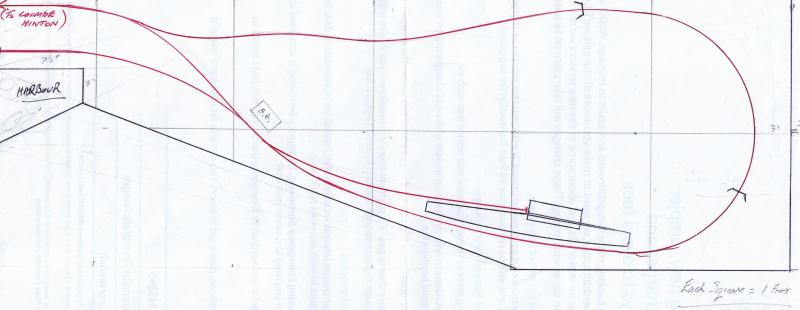

Playing with Anyrail now, this should be fun!

The curve is the recently fixed and walled decent into the Riverbank Siding area.

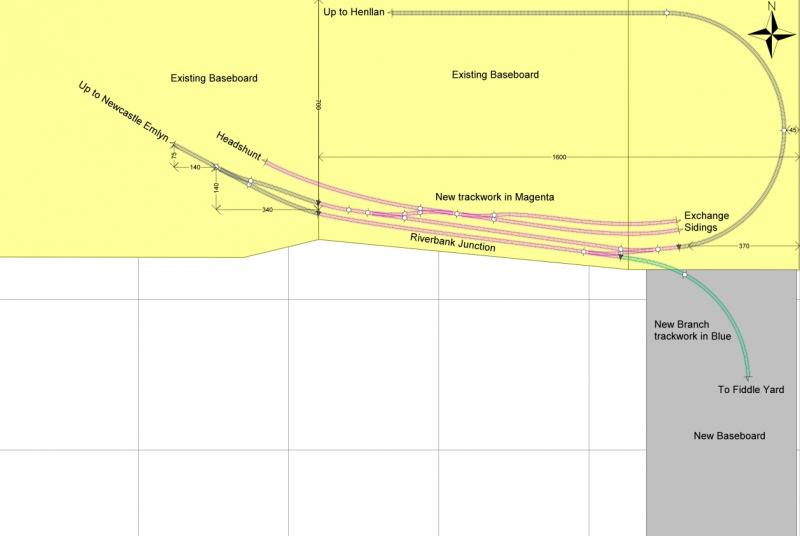

Riverbank is currently a simple passing loop but it's too small and there is a reverse S-bend leading into it. The plan is to straighten it out, add a couple of exchange sidings and a branch that will lead off to an under base board fiddle yard.

This section of track is already on the lower level, all I have to do is continue the branch at the same level over my work bench.

Hopefully all will become clear as Anyrail wrestling progresses.

Marty

Posted

Inactive Member

I have never been able to work that anyrail thing.

Good Luck,

Derek.

Posted

Banned

Cheers, Gary.

Posted

Full Member

Stand by…

Posted

Full Member

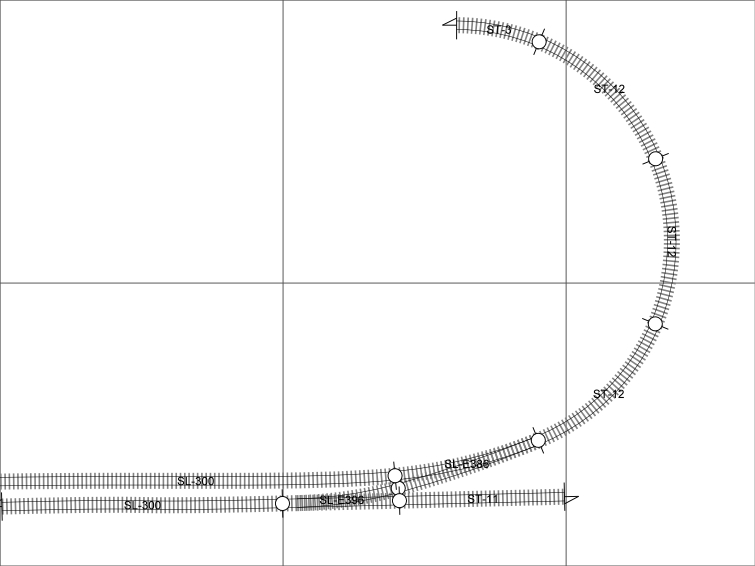

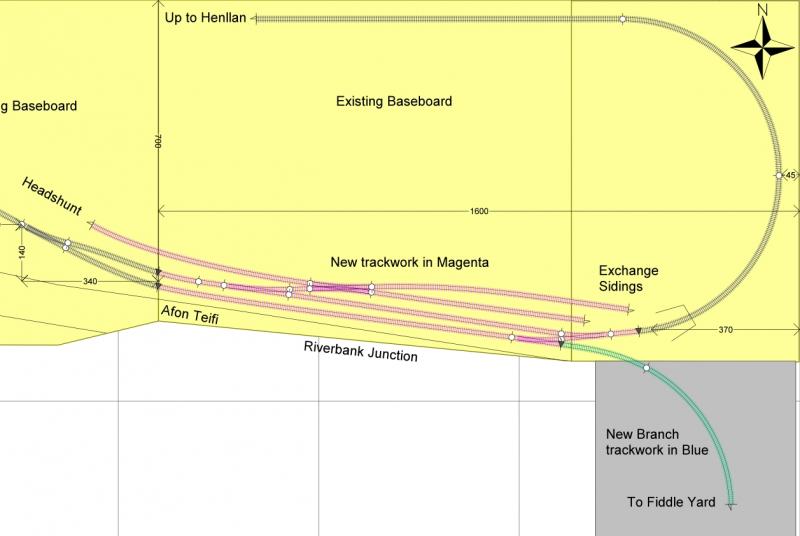

This is something to mull over at work this week.

Any thoughts, comments or suggestions welcome seeing as we must have one of the best collections of model railway brains on the interwebs….. would be silly not to use them.

The concept is to allow trains coming from the fiddleyard (more on that coming up) to run through to Newcastle Emlyn, reverse via the Riverbank Junction passing siding to Henllan or leave stock in the exchange sidings for pick up.

cheers

Marty

Posted

Inactive Member

Ken

'It don't mean a thing if it ain't got that Swing'

Posted

Full Member

Imitation is the highest form of flattery.

Nice return loop. You are braver than me though, I'm too chicken to play around with reversing the electrical polarity like that.

I like the bay platform too…. have you got a story for it yet?

Marty

Last edit: by Marty

Last edit: by Marty

Posted

Inactive Member

Re the loop, I'll be asking Trevor how to go about electrifying that in due course! :roll:………….Nice return loop. You are braver than me though, I'm too chicken to play around with reversing the electrical polarity like that.

I like the bay platform too…. have you got a story for it yet?

Marty

Story, hmmm? Well sort of: it's certainly going to be all countryside i.e., farmland, apart from the small extension to the harbour/quayside but as I like making buildings so much there will probably be a small village and a farm etc. However I'm not going to start on this - much as I want to(!) - until the main Coombe Hinton to Barton Tracey area is more or less finished, in fact this will hopefully spur me on!

Ken

'It don't mean a thing if it ain't got that Swing'

Posted

Full Member

Still, something to plan for all the same.

The obvious change to the plan above was to replace two of the turnouts in the sidings with a double slip.

The only problem, well two of them really, is, one, the double slip is code 55 and all of the rest of my track is code 80 and, two, I'll have to buy it as I don't have any in stock.

Peco say that the code 55 and code 80 is compatible with the application of a flat file to level the rail heads. I believe that the sleepers of the code 55 have to be "modified" or removed to allow the rail joiners on.

Does anyone have any experience of this?

I've change the exchange sidings exit point to code 55 long as well in the diagram. My thoughts being keeping the profile the same for two adjacent turnouts/crossovers has to help reduce the likelyhood of derailments.

Cheers

Marty

Posted

Inactive Member

By modifying code 55 sleepers I would guess they are talking rail chairs. A lot depends on the amount of rail left free at the ends,You may have to nick the plastic chairs on the last sleeper to allow the joiner to slide home.

Just my little thoughts.

Derek.

Posted

Full Member

I think I'll go code 55 for all of the loop and sidings and make the transition on plain track rather than at points. Got to be easier that way.

Marty

Posted

Inactive Member

Best of luck with it.

Derek.

Posted

Full Member

… and I'm working on a map to show why…

Update on the laser cut template for the N scale halt support legs today too. Quoted $100 for a 30 mm x 40 mm x 1 mm plate of stainless steel. Basically the setup cost. We are now waiting until my mate has a job to go to the laser cutter and he'll just add the file to the rest.

Luckily there are other things to do.

Marty

Posted

Full Member

Joiners fit the bottom flange of the 55 so there's no need for any filing of the 80.

Cheers MIKE

I'm like my avatar - a local ruin!

I'm like my avatar - a local ruin!

Posted

Full Member

Marty

Posted

Guest user

I can't help but admire the baseboards. Some nice long sweeping bends. I take it that they were cut out using a jigsaw a steady hand needed there.

Looking good

Toto

Posted

Inactive Member

Derek, Peco cheat, code 55 is actually code 80 with 25 of it buried in the sleeper, it has 2 flanges one in the sleeper and one on top of the sleeper, when joining 80 to 55 it is necessary to pack under the 55 sleepers to bring the rail tops up level with the 80. (link to Google image)

Joiners fit the bottom flange of the 55 so there's no need for any filing of the 80.

:shock:Thanks for that info Mike,Sorry Marty I was unaware of Peco and its ecentric ways :roll:.

Cheers,

Derek.

1 guest and 0 members have just viewed this.