Granby Junction 1948 N. Wales

Posted

Full Member

GWR/LMS OO Gauge DCC RR&Co

I love seeing your Scalescenes buildings take shape John - always excellent stuff.I can see sales of sail makers needles going through the roof - how's that for 2 puns in a single sentence !!!

It's looking really good - can't wait to start my cobbling of industrial units on my lift up but I've got a viaduct to build first !

Have you come up with a plan for the roof within the low relief builds or will they all butt up ?

'Petermac

Posted

Full Member

As roofs in our hobby are always on show, unlike in real life, it’s important they look good and the Talbot is really coming to life.

Looking forward to more,

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

I love seeing your Scalescenes buildings take shape John - always excellent stuff.

I can see sales of sail makers needles going through the roof - how's that for 2 puns in a single sentence !!!

It's looking really good - can't wait to start my cobbling of industrial units on my lift up but I've got a viaduct to build first !

Have you come up with a plan for the roof within the low relief builds or will they all butt up ?

Thanks Peter

I am glad you like it so far.

I wouldnt quite say a plan for the roof…..more a concept:roll::shock:…….hopefully it will work well and Bill will approve.

I am really enjoying the developments on Maxmill……its also been very helpful……..thinking ahead I have a bit of a footprint issue when the hotel is completer….I need to reclaim some more land from fresh air………having seen Phil’ s work in detail Will’s sheets I think I may enclose my reclaimed land with a wall of them…..better get you order into Hattons quick!

:lol:

Posted

Full Member

Thanks BillI may not strictly be a card modeller John, but I've a keen interest in architecture and construction, as I rather think does John Wiffen, which is why his models are so good, well at least when made with competence. Yes, I need more practice.

As roofs in our hobby are always on show, unlike in real life, it’s important they look good and the Talbot is really coming to life.

Looking forward to more,

Bill

Nothing like some pressure to make sure the roof meets with your approval:lol:

Posted

Full Member

I was half way through my order and someone nicked all their stock just as I got to the checkout !!!

'Petermac

Posted

Full Member

:oops: :oops: :oops: I didnt take them all….there should have been some left :pedalHave you just grabbed the last of Hatton's stock John ?

I was half way through my order and someone nicked all their stock just as I got to the checkout !!!

Posted

Full Member

It was whilst I was waiting for card authorisation that they emptied my basket saying there was no further stock.

I've just had an e-mail from them confirming the order and receipt of payment !

I'll either get them or I won't ………..

I did try elsewhere and found some at only 25p more but they wanted £16 postage !

I think, judging by the number of shops out of stock, we modellers will soon grind to a halt. I see Hattons still don't have my electrofrog points in stock and that's from months ago.

'Petermac

Posted

Full Member

Glad you got your Will sheets….I was so embarrassed I started checking Canada France postage rates

Posted

Full Member

As I said John, I'm still not absolutely sure it's going to arrive. It was a very strange process. I'll check the card tomorrow and see if it's been paid for ……..

I've just been checking on how people use the stuff - and also realised the sheets are only half the size I'd thought ! It's going to be a very expensive viaduct I think ….

'Petermac

Posted

Full Member

I would continue experimenting with all three mediums. The experts advise against mixing card and plastic but I think it can work ok….certainly there a few examples on Granby……you might be able to save time and money with some judicious mixing?

Posted

Full Member

Thanks Doug thats very kind of you. As you say it is amazing just how quickly one can gather information……provided you ask the right question of course. The questions I asked didnt, sadly, produce the right answers :oops:Would tanned hides be bundled/baled and transported unwrapped or would they be wrapped in sackcloth?

Best

This might help.

https://cargohandbook.com/index.php/Hides_and_skins

A fount of knowledge. Just think, a relatively short time ago one would have needed to don an overcoat and take a bus ride to the nearest library to access such esoteric information!

Douglas

Doug

It seems I can use bales or bundles ….now I have to dig a bit more into tannert layouts

Thanks again for your help

Best wishes

Posted

Full Member

I've worked in close proximity to at least two tanneries in England. One being Connolly's at Colliers Wood in South london and one in Leeds where Yardleys transport had their yard just off Meanwood Lane. I'm happy to say that the latter was the one where I more or less only visited to swap trailers. The common theme is that they both stunk. One in Australia as well… no I don't work at or around these places by choice, they seem to follow me like a bad smell.[user=312]Chubber[/user] wrote:Hi DougPerhaps we are forgetting that the windows would all have been sash hung, and as such there would have been no reason why the cleaners would not have been able to slide the lower and the upper sashes half down, clean the the top outside of the outer sash standing on a step ladder, and the lower half by ducking through the lower opening to sit on the sill, pulling the outer sash down on their thighs and cleaning the lower half of the outer sash.

This how my mother cleaned our windows.

I'm sure there is a scene from an Ealing comedy that shows one of the actresses doing just that.

Doug

Of course…. why didnt I think of that……and all the widowers I am using are casement

:off topic

While you are here can I pick your brain on an unrelated matter?

While researching Wrexham (Granby) I was reminded that therewas a very active leather tanning industry there.

I have another dark satanic mill from which I intend to lower something…(I havent forgotten about the stays for the other load you advised on….honest :oops::oops::oops:

Would tanned hides be bundled/baled and transported unwrapped or would they be wrapped in sackcloth?

Best wishes

Cheers Pete.

Posted

Full Member

Connollys supply the leather to the likes of Rolls Royce so a very up-market smell !

'Petermac

Posted

Full Member

Posted

Full Member

I used Greenheart when I was working at a timber yard. It was so impervious to everything that it was still good when the old flour mills in Brisbane were demolished after I don't know how many years of being used as pilings in the river.Just to add to this - my dad was a joinery up around Burnley in Lancashire and for a while he was the resident joiner at a local tannery. he said he sort of got used to most of the smell although there were some areas he tried to avoid. He also said that part of it was the chemicals used. From his perspective they were so corrosive that anything made from wood was quickly rendered useless - that was until they found this really hard, almost black wood, that was from Africa. He said the biggest problem with that was that you had to sharpen your saw after nearly every cut. I seem to remember a bit arriving home at one point and being used on a certain trolley (unpowered go-kart he built for us kids).

Cheers Pete.

Posted

Full Member

https://www.youtube.com/watch?v=LOy2GuaP8Mo

Posted

Full Member

Part of the charm of the hobby Colin………I am afraid it tends to reflect my butterfly approach as I flip from one unfinished project to the next. I am so far behind I am now making summary lists of lists:roll:

I do hope that your ankle is progressing well?

Best wishes

Posted

Full Member

All the above chat about window cleaning old buildings from cradles and hoists reminded me of this classic tale of woe:

https://www.youtube.com/watch?v=LOy2GuaP8Mo

I can watch/listen to that a hundred times and still get a good laugh out of it. A classic along with fork 'andles and the chandelier.

Cheers Pete.

Posted

Full Member

I do hope that your ankle is progressing well?

Best wishes

Hi John.

Thanks for asking. I posted all the latest details on Weston-Heathfield last Thursday. Since then improving even further. Lots in garden to catch up on now.

Colin

Posted

Full Member

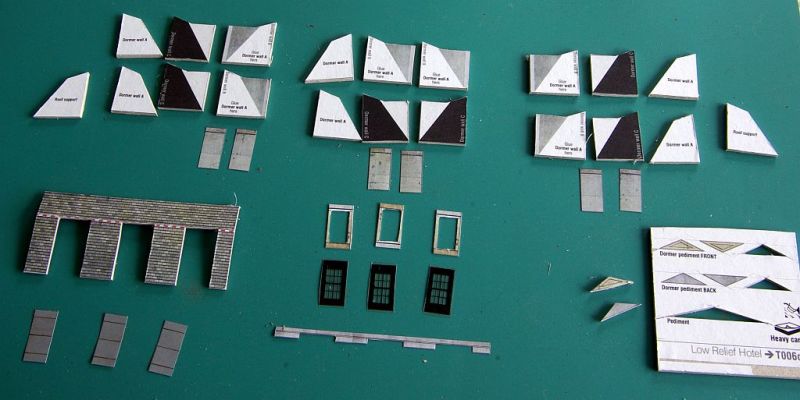

The plant rooms were pretty straight forward:

The Dormer Windows less so!

I am always amazed by the ingenuity of John Wiffens designs. Not just for the attractive, three dimensional exteriors

the creation of all manner of structural support elements using only card and paper.

Many of these structures are small, intricate and challenging…..Dormer Winows would be a good example

Here are the pieces needed for three windows…………I will need eighteen eventually

"

"The key elements are at the top…. 18 pieces cut from 2mm card and measuring approx 1" x 1

There are three different shapes which are laminated together to form substantial 6mm frames for each window

All three shapes, A B and C, do have one common feature…..the short angle cut at the top designed to support the upper dormer roof

(A) Supports the lower dormer roof

(B) The actual window frame…..the leading edge is exposed hence the "xtome" cover.

(C) Is identical to (B) except the depth is reduced by 1/8". Thus when laminate together B and C form a rebate into

which the window will fit.

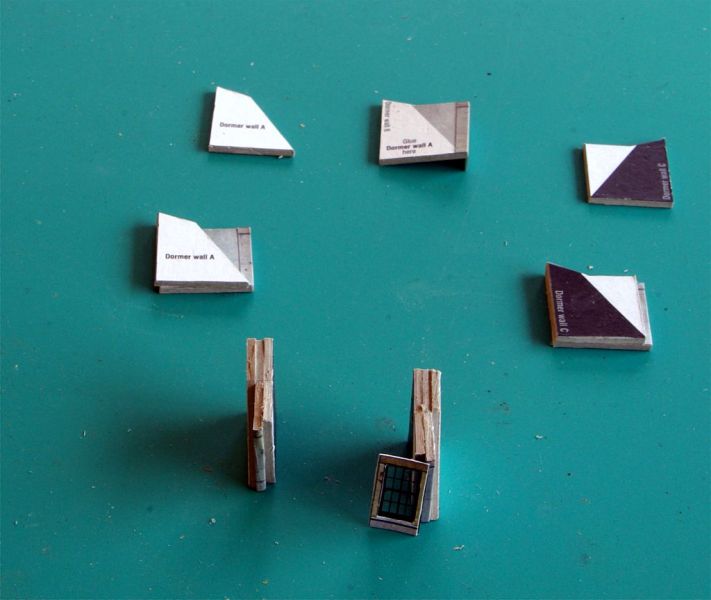

The shot above and the next close up do

highlight the difficulty of achieving smooth uniformly accurate cuts with 1" material!

The nominal 2mm card I use is actually 2.2mm.I have been caught before by "thickness creep" and thought I had made adequate allowance. Wrong! The roof window openings requires a lot of fine trimming to accept the window sub assemblies

The window itself consists of a very thin, cutout frame mounted on light card and then backed with a film window print. This flimsy structure proved be very flexible when glued to the two unsecured 6.6 mm side frames.

As you can see:

I was not a happy camper at this stage.

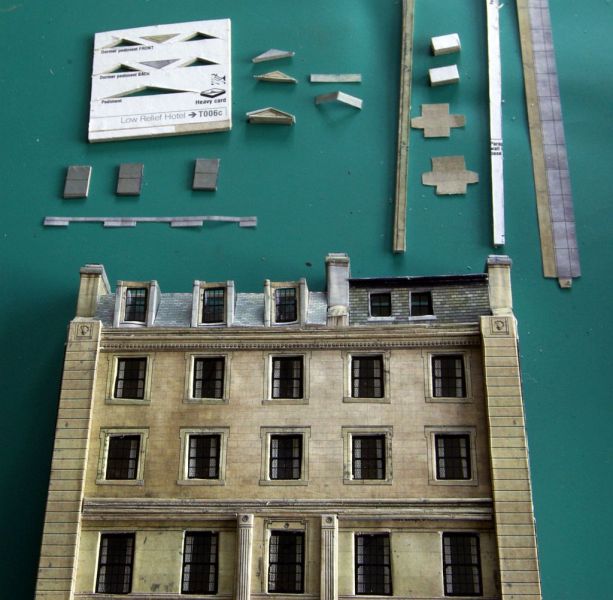

However after a lot of fettling and the addition of the individual dormer rooves I was able to secure the main roof and add the minute finials……which conveniently hide some unsightly gaps

I felt a bit better with this shot

The shot above is a good example of vertical thickness creep.The balustrade cap should extend across the entire frontage including the end buttresses. The buttresses are the correct length. The addition of muliple internal floors and ledges has resulted in the building itself being 3mm taller than designed.

To conceal the gap I have made little caps from scrap for the buttresses……thinking about it, they will look better if I recover them with paper that matches the balustrade cap………..another job for the list!

All done except for chimney pots…….they go on right at the very end……….in March?

Two down……..one to go

I am departing from the design for the centre module. Rather than fit a third plant room I propose fitting a row of six dormer windows…I am nothing if not a glutton for punishment.

However these windows will feature the new improved Mark II sub assembly…….3 ply side frames of 2mm max mount board joined by a 3/8" floor and rear wall…….solid as a rock!

Now to finish with something completely different.

6818 Hardwick Grange, one of my sadly neglected 4-6-0s, leaving Granby Shed:

1 guest and 0 members have just viewed this.