Granby Junction 1948 N. Wales

Posted

Full Member

GWR/LMS OO Gauge DCC RR&Co

Thank you for the clarification John.I regret that, with all that is going on at the house, I have only skim-read the last few weeks' worth of posts from everybody

To be honest, I really only looked at the pictures!! :oops:

To be honest, I really only looked at the pictures!! :oops:Barry

Shed dweller, Softie Southerner and Meglomaniac

Posted

Full Member

John - very interesting.

I thought that the drivers had a groove machined into them to accept the traction tyre. I can recall older locos starting to waddle somewhat when the tyre either fell off or snapped - the wheel/groove not making a good connection with the track. Is this not the case with the 14xx?

Barry

Hi Barry,

Likewise, over on W-H in May I sacrificed an old non-running Airfix to get suitable non grooved wheels for my Hornby 48xx. This left me with an Airfix sporting all 4 wheels grooved - 4WG? Anyway, not being one to waste anything I ground them all down to remove the rims and a bit more to get the right profile. After a clean of all the electrical bits it now runs quite well. There's a pic there of it sporting 4 "new" bright shiny wheels (W-H post #176)

Colin

Posted

Full Member

Reading through your "what I did", I did wonder if HM Armed Forces gave you a proper sten gun - they were indeed, a "bare bones" weapon but I've never seen one with wheels ……………………….. :lol:

It must be extremely satisfying to resurect something from the scrapyard and turn it into a good runner. Whilst I'm sure Mr Zimo and the supercap helped, the real credit must go to you, the engineer.

Stripping things down and reassembling is the sure way to understand how and why things work - in a former life, I did cross-country trialing in a Series 1 Land-Rover. As a result of regular stripping and reassembling, I could, single handedly, remove, strip, reassemble and re-fit a gear and transfer box in less than a day. In this case, you were fortunate enough to have a supply of subject matter. As a result, you have probably become Canada's guru on the 14xx locomotive.

Just a question - what's the Kapton tape over the bogie wheels holding in place ? Surely not a speaker ……………?

I'll be revisiting your post frequently I think - I've been digging out some of my older DC locomotives with a view to converting them so posts like yours are invaluable.

Many thanks but primarily, congratulations on a not-too-easy job very well done !!

'Petermac

Posted

Full Member

Phil

Posted

Full Member

Referenced for future use, as I have a pair of ancient 14xxs in the 'too difficult to tackle at the moment' box!

Best,

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

No speaker Peter :lol: although there is masses of space in the bunker……thats where the Supercap is going. Its the decoder that is wrapped in tape and then immediately over the pony wheel there is a small strip of tape securing the RH feed.

So this post is a wrap up of the Dapol 14xx conversion

I havent worked out yet which schedules 1401 will operate on a regular basis……..Autotrain or B Set….. but it will definitely be on the lower level Cynwyd Branch:

It will probably be the B Set……..she performs so reliably and with such precision at slow speeds that consistent coupling and uncoupling is a given.

I have produced a very short video to demonstrate this. .

1401 hauls a two car set and van into Cynwyd. Uncouples the van from the carriages and pulls it foward to clear the bay turnout. Once clear the van is propelled into the bay and uncoupled. The loco then propels the uncoupled van to the buffers at the end of the bay. The loco then returns to the carriages in the running line, couples and continues to Granby.

Its probably no surprise that the six movements or schedules in the sequence are all performed automatically! I click a virtual switch to start the first schedule and then everything follows including the Kadee Uncoupling Shuffles.

The shuffles are accomplished by using the "Short Distance Moves" at speed step 02

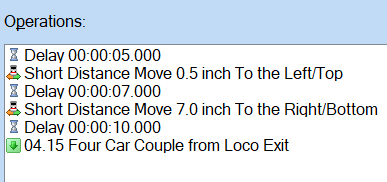

As an example here is an extract from the LMS Suburban posts in April:

In the video the increments I used are even smaller …….0.3 inch and 0.2 inch. I was amazed how reponsive the 1401 was.

The move were the uncoupled van is pushed to the buffers was something of a breakthrough for me. Not wanting to bore everybody I have added a paragraph after the video for the hard core RR&Co enthusiasts.

.

So without further ado here is the video

[yt]wxKuSdgXWt4[/yt]

For RR&Co followers:

The short distance move command (SDM) is a brilliant innovation. However it is exactly that a move over a short distance. You can use the command to move a loco over longer distances but only at threshold speed. A loco crawling for 6" at 2 mph looks daft.

Since the introduction of SDM you can no longer use the Train Operations like /Reverse/Speed at the conclusion of a schedule. TC issues an error message "cant change speed or direction of a schedule while under control of a schedule"

I struggled to find a way round this for ages…..finally posted a query on the RR forum and got virtually no response……….re read the manual……there's a novel approach. I discovered that you can attach a switch to a specified block. Train Operations in that switch can be automatically carried out by a loco assigned to that block!

So I created a switch for the bay and had it turned on as the last command of the bay schedule . The first switch command terminated the schedule and was followed by commands that moved the loco forward at 5mph for 4 secs and then 3mph and 2 mph so the van just kissed the buffers.

I had no idea this could be done…..the explanation in the manual is typically opaque……..was I being dense and is this, in fact, a well known, often used, option? Comments/Discussion much appreciated

Best wishes

John

Posted

Full Member

Michael

Posted

Full Member

Do you have anything creating drag on the coaches or are they just weighted ? I didn't notice any jiggling in either direction. Whenever I try it, admittedly with wagons rather than coaches, they jig around like the bits of plastic they are - it destroys all semblence of realism ………

That little video is one of the smoothest movements I've ever seen. Well done GWR ………………………. :roll:

'Petermac

Posted

Full Member

Thanks Michael. I am glad you liked the video. I think it demonstrated the precision and accuracy of the 14xx far better than anything I could write. RR&Co demands precision…..its all very well saying, in effect, run at 15 mph and then stop 36†into the block……if the loco stalls or even stutters you are toast. My conversion to Zimo decoders and Stay Alive has made a huge difference to my operating.Lovely work John - very impressive loco and a great demonstration of the freedom Kadees can give - not to mention your skill at programming the tasks. It must be a real delight to see the "new" loco perform so well. And even a little pushing of a wagon into position post-uncoupling, not just left where it was….I do love that manoeuvre when it works well. It feels like a bit of magic every time I do it!

Michael

The post uncoupling manoeuvre is indeed magic…..I actually run a version of this van sequence in my dairy operations and I think I will incorporate the push to the buffers. ……….less sure whether I am bold enough to use it in the goods yard where my track is somewhat uneven!

Best wishes

John

Posted

Full Member

Thanks Peter that is very kind of you.That's fantastic John - lovely little loco performing brilliantly at very low speed. There were times, many times, when it was hard to believe it was all done automatically - the movements were so delicate and so precise.

Do you have anything creating drag on the coaches or are they just weighted ? I didn't notice any jiggling in either direction. Whenever I try it, admittedly with wagons rather than coaches, they jig around like the bits of plastic they are - it destroys all semblence of realism ………

That little video is one of the smoothest movements I've ever seen. Well done GWR ………………………. :roll:

I did have problems coupling to the coaches Its not visible to the naked eye but there is a very slight incline and when the couplers initially touch there is risk the coach will run away. In the end I had to add a second coach just to provide some stability.

Wagons do need some added weight for coupling and also to avoid derailing when propelled……I will probably use Ron’s idea of inserting a Kadee spring into a bearing just add a bit of resistance

Best wishes

John

Posted

Full Member

Posted

Full Member

Thank you Dave . I am particularly glad you liked it. The last section was primarily for you!Just goes to show, yet again, what you can achieve with RR&Co. What "you" can achieve that is not us mear mortals. Seriously, you must have hundreds of schedules set up in RR&Co, how do you find the one you want. I guess some sort of clever naming convention - or is there a way to have some sort of tree structure - now that would be really useful. Only got about a dozen myself at the moment and already keep changing my mind on the naming convention.

You can set up a tree structure. In the Block Diagram or Despatcher screen you can create new files. You can then drag schedules into these files….you can create further sub files…………just like Windows.

The files can be open or closed which is a huge help in cleaning up the Despatcher Screen

I use a two digit code to name the files and identify the different operations eg:

01 Up Express……….08 Cynwyd B Set……….47 Down Main Goods………..70 Shed Entry etc

Individual schedules are named using the group prefix followed by a unique two digit suffix.

As an example I have a routine where a B Set shuttles between Granby and Cynwyd with a loco exchange at Granby and a run around ……this involves 8 to 10 schedules

The schedules are numbered in the order in which they run

08.10 Granby P3 - Cynwyd

08.11 Cynwyd - East Home Uncouple LE

08.12 East Home - Loop - West Home LE

08.13 West Home - Cynwyd LE Couple

08.15 Cynwyd - Granby P3

08.16 Loco Spur - Loco Entrance LE

etc etc

I try and make the schedule name as descriptive as possible…….what seemed ultra clear in January can become very obscure 3 months later!

TC has no limit on the number of schedules you create. So I have many duplicates so they can be numbered and stored like this. Schedules are very easy to copy, rename and fine tune.

Hope that answers your questions and wasnt too convoluted

Best wishes

John

Last edit: by John Dew

Last edit: by John Dew

Posted

Legacy Member

Only just caught up on your thread.

Sorry to hear about the 3 days of hell trying to find the short that occurred with the amount of wiring many of us have on our layouts its something that can happen to any of us at any time. When its something on a electronic board that is often far more difficult to find. Track related problems if your hearing is fine you can hear if you listen carefully.

I have a number AD8FX units to date i have not had any problems with them but i note the Cobalt IP motors have been mentioned specifically about loosing their address this does seem to be a common problem with them especially after a short has occurred as there are numerous posts on the DCC concepts forum regarding this.

My only beef with the AD8FX decoder is that on my Ecos you have an option of firing all accessories on startup an option i have always used in the past so it ensures all points dont just sit there for ages withought moving.

With my Ls150 units and the switch 8 i use this has always worked fine with anything on an AD8FX it does not work.

I have asked on the DCC concepts forum about this but never got an answer why it does not do it as all the Ecos does is send a signal out in sequence to each accessory address twice as it would normally do when operated.

Great work with the 14X John time well spent their and enjoyed you shunting video.

Brian

OO gauge DCC ECOS Itrain 4 computer control system

Posted

Full Member

Some very nice sturdy camera work also!

Posted

Full Member

Hi BrianHi John

Only just caught up on your thread.

Sorry to hear about the 3 days of hell trying to find the short that occurred with the amount of wiring many of us have on our layouts its something that can happen to any of us at any time. When its something on a electronic board that is often far more difficult to find. Track related problems if your hearing is fine you can hear if you listen carefully.

I have a number AD8FX units to date i have not had any problems with them but i note the Cobalt IP motors have been mentioned specifically about loosing their address this does seem to be a common problem with them especially after a short has occurred as there are numerous posts on the DCC concepts forum regarding this.

My only beef with the AD8FX decoder is that on my Ecos you have an option of firing all accessories on startup an option i have always used in the past so it ensures all points dont just sit there for ages withought moving.

With my Ls150 units and the switch 8 i use this has always worked fine with anything on an AD8FX it does not work.

I have asked on the DCC concepts forum about this but never got an answer why it does not do it as all the Ecos does is send a signal out in sequence to each accessory address twice as it would normally do when operated.

Great work with the 14X John time well spent their and enjoyed you shunting video.

Brian

Good to hear from you…….how is the fishing?

Glad you liked the video

RR & Co recently allowed you to construct a file that activates after every start up……which is what I use to throw certain key turnouts including the ones served by the ADSFX …….before that I had a virtual switch that I tried to remember to throw on start up. Could you do something like that with ITrain just for the ADSFX?

Best wishes

John

Posted

Full Member

That video is fantastic. Some lovely movements there, I’ll have to investigate the Zimo decoders.

Some very nice sturdy camera work also!

Thanks Chris that is very kind of you.

I only discovered Zimo a year ago……they are seriously impressive and great value. I was totally committed to Lenz and had very good results from them…..but somehow Zimo just has the edge plus its much easier to add Stay Alives.

The camera was an Iphone in a Gorilla thingy with its legs wrapped around the top of my camera tripod……not too many smooth panning shots!

Cheers

John

Posted

Full Member

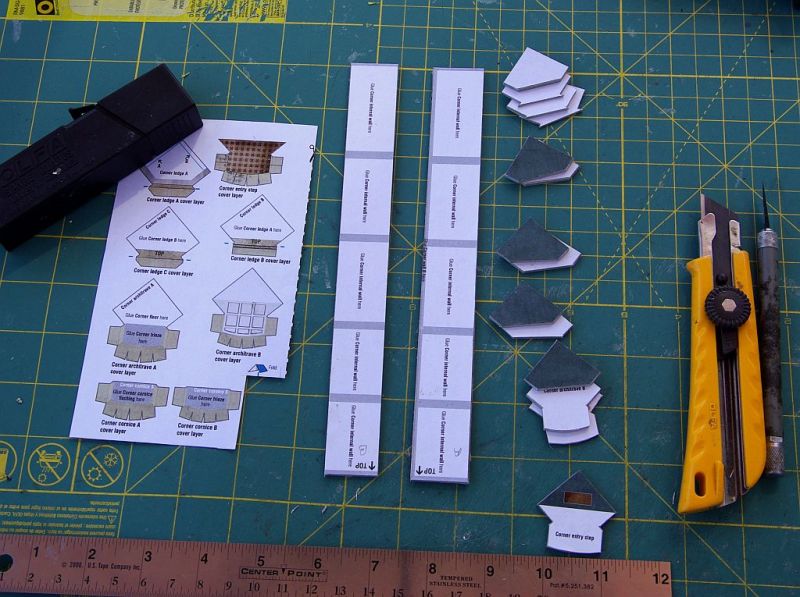

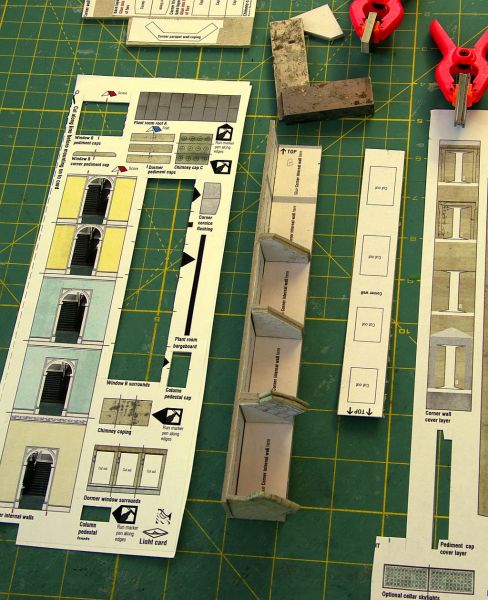

Time for some modelling :

Time for a bit more work on the Station Hotel, last seen plonked on St Asaph Square in February.

The plan is to expand the low relief kit into a full size model …..facing the square and backing on to the railway in the rear………so two sides and the back still to be built ……and I still have to work out how to deal with the roof!

First job is to build one of the corner sub assemblies which will connect the front with one of the side units

It was surprisingly easy and quick to build………so quick in fact that I omitted to take photos of a couple of the stages but hopefully these shots give an idea of the sequence

Next stage is to build one of the sides. This will take a lot longer because it is not only more complicated but I will have to do a fair bit of cutting and shutting with the base templates in order to replace the elaborate entrance way with a third matching window.

In other news, my new Hornby large prairies left Liverpool early last week……..delivery times from the UK vary significantly particularly with Covid ……..but next week is a remote possibility. Its a delivery that I am looking forward to with a mixture of pleasurable anticipation and some trepidation. Reaction to the model has been mixed, particularly in relation to its running. Some owners are clearly very happy with the model…..others less so, with reports of the pony wheels derailing and/or uneven motor performance. I do hope my Prairies fit into the former group……

However there is no point in worrying…….right now I am focused on cutting out 36 perfect window apertures!

Regards from a very sunny Vancouver

John

Posted

Full Member

I was wondering what you were up to and now looking at your splendidly sited work table, I can see that you have been modelling in some style and comfort, so keep up the good work.

It's been rather warm here as well for several weeks, without rain and it's difficult to see where the courtyard gravel and grass start or stop, as there're exactly the same colour. Rain is much needed and we have a strict evening watering regime to ensure a colourful environment, excepting the lawn of course!

Good to see your builders are back on the hotel, which will help even more visitors get the most out of their stay in Granby.

I do hope your new prairie is a good runner. They look absolutely superb and I must admit not to have run mine yet, but will rectify that tomorrow and will keep my fingers crossed for a good outcome.

Take care,

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

I will follow your hotel project with great interest. I too, want a 'double-sided' hotel for Wombat Creek. Please keep us updated with the progress.

Cheers,

Claus

www.flickr.com/photos/ellef/

Claus

www.flickr.com/photos/ellef/

Posted

Full Member

Hi John,

I was wondering what you were up to and now looking at your splendidly sited work table, I can see that you have been modelling in some style and comfort, so keep up the good work.

It's been rather warm here as well for several weeks, without rain and it's difficult to see where the courtyard gravel and grass start or stop, as there're exactly the same colour. Rain is much needed and we have a strict evening watering regime to ensure a colourful environment, excepting the lawn of course!

Good to see your builders are back on the hotel, which will help even more visitors get the most out of their stay in Granby.

I do hope your new prairie is a good runner. They look absolutely superb and I must admit not to have run mine yet, but will rectify that tomorrow and will keep my fingers crossed for a good outcome.

Take care,

Bill

Thanks Bill

Hope you are enjoying your summer despite Covid. We have a night time watering system…..when we had the boat we were away so often that some sort of automated irrigation system was essential….over the years we have built up quite an inventory of hose, soakers, sprinklers and timers……its a bit Heath Robinson but it kind of works!

I am amazed at your patience…..I cant imagine getting a new loco without trying it out! If you weaken and do try yours out before I get mine do let me know how it performs. Not sure if you have been following the thread on Rmweb but you need to check the tightness of the connecting rod retaining screw! Apparently the front bogie doesnt have enough vertical movement,……various solutions….longer screw or file down the mount. You are far more mechanical than I so I will be interested in your approach.

Best wishes

John

1 guest and 0 members have just viewed this.