Granby Junction 1948 N. Wales

Posted

Full Member

GWR/LMS OO Gauge DCC RR&Co

I only use Zimo so can't say, but ESU are one that may do it. Give them a headache. ;-)

Cheers Pete.

Posted

Full Member

Hi PeterI was about to make some reference about tantalums being thrown by small children but had another, more profound, thought.

If the loco continues for some distance after the power is cut, how will this effect RR&Co or can you either specify exactly how far it will run or alternatively, does it always run the same distance, in which case, you could cut the power early ?

If not then, as with many things in life, solving one problem would appear to precipitate another ………………

A number of people have mentioned the problems that could arise if the loco could run for a significant period of time on track without power.

Its not really an issue for me……it could only happy if I was running manually ie with the DCC throttle and I dont have any lengths of un-powered track anyway.

When running automatically with TC there is an assumption of constant power, the supply of which is controlled by the software.. When a loco is stopped in a block……temporarily in a station or at the end of a schedule, TC issues commands to progressively slow and then stop the loco at a previously specified distance from the entrance to the section. It does this by a series of time and distance calculations based on the speed the computor has specified. If the loco hesitates even for a moment over a speck of dirt these calculations are screwed (stronger words come to mind)……….the loco stops short because the computor didnt know it hesitated.

You were spot on in an earlier post when you talked about the advantages of stay alive can be for both sound and automatic operation.

Thinking about it I guess I will need to check if there is surge in speed when the stay alive kicks in…….that would cause the loco to over shoot so in that case I may need to use Cv 153 (thanks for that Pete!)

Cheers

John

Posted

Full Member

RR & Co really does seem to be a very clever system, well thought through and with most, if not absolutely all, eventualities covered.

On average, if there is such a thing, how long does it take you to plan a full movement for a single train - or are all the sequences done simultaneously ?

'Petermac

Posted

Full Member

A single schedule …..start in block A , pass thru block B and finish in Block C …..takes very little time….5-10 minutes setting up on the computor and maybe 10-20 minutes testing…..I invariably need to make some adjustment.:oops:

A complex routine involving a series of linked schedules with changes to the train structure like loco exchanges can take many hours to get right.

Patience is an essential virtue.

Cheers

John

Posted

Full Member

Really decent stay-alive capacity comes at a price - £22 or more. And they are big. Last year I was playing around with a LiPo battery system powering an NCE radio equipped decoder using a converter card to push 16v into the decoder from the LiPo. 20 minutes trundling around with no power to the track. Took all the space in the tender though.

Most decoders limit the time that a stay alive can put power in as well. And there are other complications such as resistors that are required in some setups. One thing I noticed recently was that a decoder and attached stay alive was none-functional if the stay alive wasn't charged. Interesting to see how the sounds came before motor function as it sat on the track charging. None-sound decoders present fewer issues compared to sound decoders.

I found that properly wired frogs and points, the usual source of conductivity issues, along with clean track, wheels and pickups, eliminated any need for stay alives. If they come with the decoder I usually keep them.

Nigel

©Nigel C. Phillips

Posted

Full Member

I suggested CV153 because of one loco running into another one or against points. The thing is, I know nothing about computer control so can go no further. Zimo do a SC68 capacitor pack which does come in at about £22.00 but is small and has 6,800uf which should be plenty to keep a sound loco going for a couple of seconds.

Cheers Pete.

Posted

Full Member

For many years the only RTR version available were versions from Hornby and Dapol of a very old Airfix design.

There was much excitement about 5 years ago when Hattons, in collaboration with the now defunct DJ Models, announced a brand new design incorporating all manner of new features.

Sadly, the model turned out to be a bit like the Curate's egg…..only good in part.

Here is a work stained 1407 in Cynwyd goods yard.

It is generally accepted that the bodywork is superb. There are a couple of minor design issues…the ash pan went AWOL and few people liked the recessed number plates. (I added after market plates to my model). Apart from this, visually, they were a huge improvement on the old Airfix derivatives.

Unfortunately they have proved to be very erratic performers. The coreless motor and unique gear system can sometimes make them very jerky….particularly on gradients. The biggest problem is their intolerance of the sllightest speck of dirt or uneven track.

They did appear to improve with frequent running but like last weeks 64xx still required too many nudges from the sky to keep moving.

Time to think about adding stay alive. Not a straight forward exercise…..the body cannot be easily removed!

The smoke box door is held in place by magnets and the 6 pin decoder inserted into a circuit board that just fits into the boiler……..definitely no room for a stay alive capacitor as well!

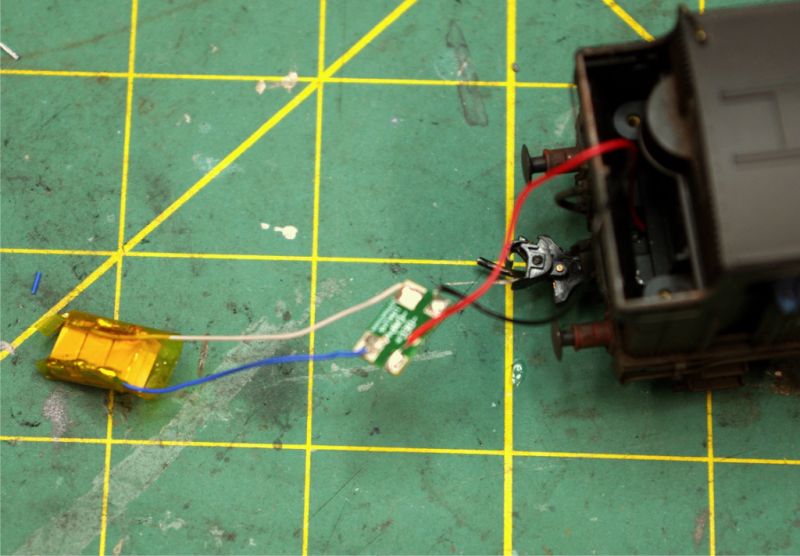

However in addition to motor and pick up wires there is an additional set of wires designed to connect with a speaker in the bunker. I dont do sound (too deaf) so I was able to connect these redundant wires to the blue (+ve) and white ground wire that John from Youchoos had kindly added to the Zimo decoder for me

Remove the coal from the bunker and the wires (now connected to the decoder in the smokebox) can be accessed

I didnt think I could fit a capacitor and lifelink board in there and in any event I wanted to try out a less expensive alternative: Tantalums

Until a couple of weeks ago I thought Tantalums were a variety of spider! Courtesy of google and wikipedia

Tantalum capacitor - Wikipedia

Three of them , wired in series, will provide about a third of the storage capacity of the KAT2 I used last week….and, along with the lifelink board, fit comfortably inside the bunker.

Once everything was put back together the loco went on the programming track and the Cvs adjusted before re-profiling and back to work

……………and the verdict?

I am afraid that the experiment cannot be described as an unqualified success.

The loco undoubtedly runs more smoothly and somewhat more reliably than before

.It is not however the sort of dramatic improvement that one saw with the 64xx. That loco is now like the Ever ready bunny …it just keeos running and and running. The 14xx, I am afraid, still stutters at low speeds over track that other locos have no problem with

It is possible the fault lies with the loco……maybe I am expecting too much from what is now known to be a suspect design or maybe it requires a more powerful capacitor than the space available…….I guess the ultimate solution could be to hard wire it to an Autocoach containing a KAT2 (I did that once with a Hornby 14xx)

I will have another go with a set of tantalums in a more conventional and moderately reliable loco to try and learn how effective they can be.

Regards from a sunny but cold Vancouver

John

Posted

Legacy Member

The tantalums you are using do you just buy them from a electronic parts supplier or are they supplied by a dcc specialist?

is there a code number or uf size you have to buy?

As you say it may be the loco but at least you saw some improvement.

Brian

OO gauge DCC ECOS Itrain 4 computer control system

Posted

Full Member

sorry to hear your 14xx problem is not resolved. It is the most annoying thing (with OR Dean Goods a close second place) that I've come across since my return to modelling. So much was promised and a potentially fine project ruined by such poor delivery of the mechanical aspects. You're no doubt aware of the 110+ pages in "the other place" on this topic with the "ays" way outnumbered by the "nays" to borrow a political analogy.

(add'n) the Tantalums you've added look to be about 1000uF in total as that's what will fit on the SACC and if so should give run on for maybe 1/4 to 1/3 of a driving wheel turn. Try the loco on your rolling road, kill power and see how much run on you get. If its a decent amount then it's unlikely to be track dirt that's your issue.

From what I've read, better pickups may not help if the fundamental problems are resistance or binding in the drive train, possibly combined with DCC / coreless motor compatibility issues. I count myself lucky as I got sound advice from the late John Flann regarding issues with DJM locos and hence avoided them.

The only permanent resolution is a total new chassis # and as that's way beyond my skill set, I've settled for the ugly duckling Hornby that after some tinkering at least runs quite well.

Good luck,

Colin

# have you seen this?

https://www.rmweb.co.uk/community/index.php?/blogs/entry/21363-new-chassis-for-the-hattons-14xx/

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

If you're using the lifelink board, what about a Zimo SC68 capacitor. Not cheap but it's flat and would probably be a neat fit in the bunker.

Cheers Pete.

Posted

Full Member

Hi BrianJohn

The tantalums you are using do you just buy them from a electronic parts supplier or are they supplied by a dcc specialist?

is there a code number or uf size you have to buy?

As you say it may be the loco but at least you saw some improvement.

Brian

I bought them from Youchoos. The owner, John Gwymer, is super helpful. The website is great and packed with useful info….well worth a visit…..usual disclaimer

The tantalums are 4700 uf…..the size and number that John recommended.

Best wishes

John

..

Last edit: by John Dew

Last edit: by John Dew

Posted

Full Member

John,

sorry to hear your 14xx problem is not resolved. It is the most annoying thing (with OR Dean Goods a close second place) that I've come across since my return to modelling. So much was promised and a potentially fine project ruined by such poor delivery of the mechanical aspects. You're no doubt aware of the 110+ pages in "the other place" on this topic with the "ays" way outnumbered by the "nays" to borrow a political analogy.

(add'n) the Tantalums you've added look to be about 1000uF in total as that's what will fit on the SACC and if so should give run on for maybe 1/4 to 1/3 of a driving wheel turn. Try the loco on your rolling road, kill power and see how much run on you get. If its a decent amount then it's unlikely to be track dirt that's your issue.

From what I've read, better pickups may not help if the fundamental problems are resistance or binding in the drive train, possibly combined with DCC / coreless motor compatibility issues. I count myself lucky as I got sound advice from the late John Flann regarding issues with DJM locos and hence avoided them.

The only permanent resolution is a total new chassis # and as that's way beyond my skill set, I've settled for the ugly duckling Hornby that after some tinkering at least runs quite well.

Good luck,

Colin

# have you seen this?

https://www.rmweb.co.uk/community/index.php?/blogs/entry/21363-new-chassis-for-the-hattons-14xx/

Hi Colin

I am afraid you are right….the solution is a rebuilt chassis …..but sadly my skillsets are are not capable of emulating the good Captain.

What did you do about the traction tyres on your 14xx? Nick Wood, of this parish, replaced them with driving wheels from a second loco……from time to time I think about doing the same.

You mentioned John Flann. What a wise and generous man. It is one of my lasting regrets that although we were, relatively speaking, neighbours we never actually met. 18 months later I still miss his posts and emails

Best wishes

John

Posted

Full Member

John,

If you're using the lifelink board, what about a Zimo SC68 capacitor. Not cheap but it's flat and would probably be a neat fit in the bunker.

Hi Pete

Youchoos offer something similar…..I was wondering the same thing……I may give it a whirl

Best wishes

John

Posted

Full Member

As the name implies, you get 6,800uf.

On the subject of the 14xx I've got and old one that I bought donkeys years ago with traction tyres. It's Hornby, so I suppose ex Dapol. Anyway, I bought a set of Ultra dear… scale wheels with no tyres and it pulls whatever a real one would pull. At the moment it's permanently coupled to a one plank wagon with a stay alive in a sort of small shed thing on it wot I built. Not prototypical but it does the job. I'll either put some shunters poles and junk on it, or I'll use one of the SC68's in the bunker.

Good luck with yours.

Cheers Pete.

Posted

Full Member

So far this year, there has been very little new stock on Granby……..so lots of excitement when the Postie made this delivery:

Bachmann's new Warflat complete with tank. I have never quite understood how the GWR arrived at their telegraphic code names for rolling stock……Toad for a brake van…Python for a CCT. ??? At least the code Warflat bears a direct relationship to the style of wagon and its usage.

Its expensive for a wagon (even with the tank) but it does represent a big step forward in terms of quality. Like the prototype, its robust and surprisingly weighty.

The detail is quite exquisite:

There is an add on pack

From the right….Vacuum Pipes, Highly detailed Jacks that fit over the buffers, Couplings and finally four gizmos that fit next to the jacks but I have no idea what they do.

I will need to check how the jacks work with the fairly tight curves leading in to the storage yard before permanently fixing them.

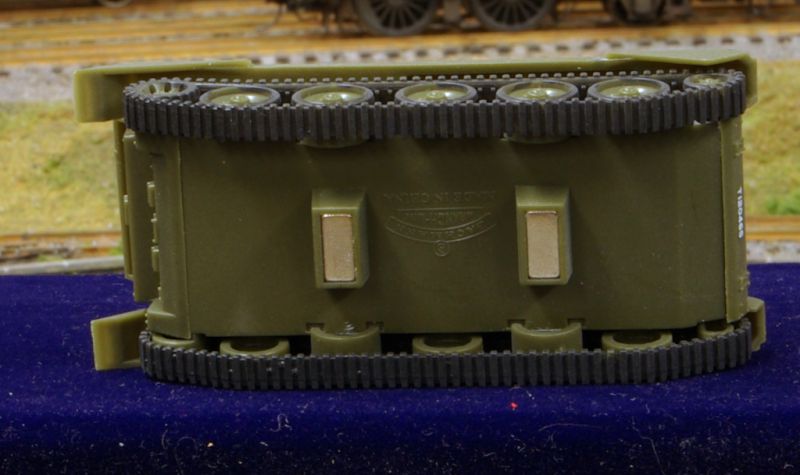

And now to the tank:

A little disappointing to be honest…….its a bit plasticky and is not really of the same standard as the wagon.

Hopefully a coat of paint and a bit of TLC will make it reasonably presentable.(The aerial recognition star will go)

The tank itself is a bit of an issue. The later version of the warflat comes with a Cromwell tank with a conventional 75 mm gun. My warflat has the correct livery for my period (1948) but the tank is (I think) a Centaur, a variant of the Cromwell but equipped with a howitzer (note the short barrel) and used for close support with HQ Squadrons. They were used by the Royal Marines at D Day but thereafter fairly quickly off loaded to allies…..not too many would be seen heading to North Wales in 1948. But thats the challenge of modelling …..rest assured I will come up with a semi convincing legend.

A more pressing issue is working out how to secure them to the wagons

The fiited magnets will help but, in isolation, would not be entirely realistic! I have to devise a method of fixing diagonal securing chains fore and aft………and then a lot of weathering. By 1948 these wagons would have seen a lot of intensive service.

Once completed they will be coupled with the Warwell and Comet. I bought the Comet kit from Millicast a couple of years ago……it does rather show up the Centaur

The Comet is totally appropriate for my period but, as you can see, is (like the prototype) out of gauge requiring a special working……..but having checked, it will squeeze through the fiddle yard.

Hopefully, you will see a rake like this but properly secured and weathered, before Christmas

I hope that I havent bored you with these ramblings……I know that I can verge towards rivet counting when it comes to the military.

Anyone know why almost all British Army tanks have names beginning with C?

Regards from Vancouver

John

Posted

Legacy Member

They do just have that plastic moulded sheen look.

The good thing is they are a good base to do a repaint to make them look more authentic.

Brian

OO gauge DCC ECOS Itrain 4 computer control system

Posted

Site staff

Did a Google search John and allegedly it stand for cruiser, (maybe).Anyone know why almost all British Army tanks have names beginning with C?

Despite many years' service in the British Army (infantry), I am unable to answer a friend's question as to why the names of British tanks all start with the letter 'C' (Cromwell, Chieftain, Churchill, Challenger, etc.). Can anybody help? | Notes and Que

https://www.arrse.co.uk/community/threads/why-the-c-in-our-main-battle-tanks.133337/

Ed

Posted

Full Member

Hi Brian

I bought them from Youchoos. The owner, John Gwymer, is super helpful. The website is great and packed with useful info….well worth a visit…..usual disclaimer

The tantalums are 4700 uf…..the size and number that John recommended.

Best wishes

John

John,

From checking the Youchoos site those must be 470uF tantalums that you've installed. That is a new product from them since I installed my 5 * 220uF set on the older SACC 16 PCB.

If so you'll have about 1.5 times the charge storage that I've got. It's still very small in terms of whats possible with bigger capacitors but those will not fit easily into our small locos. For a loco drawing 30mA the 1500uF storage Stay Alive will see you through about 0.5 sec of operation without power.

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

Hi Colin

I am afraid you are right….the solution is a rebuilt chassis …..but sadly my skillsets are are not capable of emulating the good Captain.

What did you do about the traction tyres on your 14xx? Nick Wood, of this parish, replaced them with driving wheels from a second loco……from time to time I think about doing the same.

You mentioned John Flann. What a wise and generous man. It is one of my lasting regrets that although we were, relatively speaking, neighbours we never actually met. 18 months later I still miss his posts and emails

Best wishes

John

Hi John,

sorry I missed your reply to my input, it was a busy week here!

We're agreed re chassis building as I've come to the same conclusion.

The 48xx traction tyres are a sore point. By the time I'd settled on my particular loco, the replacement driver wheels had gone out of stock and have remained so ever since. Being remote from the UK market, picking up a cheap spare loco is not a viable option for me so I make do with the front and rear powered wheels, at least my model has the sprung rear axle. (seeing peterm's comments, perhaps I should look at OEM sources for replacement wheels?)

I've read of folk who have removed the TTs and just run with the grooved wheels left on. That seemed to be a risky and potentially irreversible route so I've not gone there.

All of which explains why I was so happy with the extra performance I get with my Stay Alive. It's a job pending to post about that project.

Last edit: by Colin W

Last edit: by Colin W

Posted

Full Member

14xx chassis rebuild. The DJ model or the Hornby one? If the latter and you can wait Unltrascale wheels and gear. Or a milled chassis from AGW (both). Or a High Level chassis (both). Both these require wheels, axles, gear, motor. Just read the conversion of a DJ 14xx using the High Level chassis on the ScaleFour site. Looks….challenging.

If you have the Hornby and no TTs, Frog Snot works.

I still have the 14xx wheelset from Ultrascale if ever I get another Hornby. Unlikely. EeeBuygum probably. Maybe a 517 conversion? EM gauge, but that is easily changed to OO.

The Hornby 14xx with Ultrascale wheels trundled over dead frogs with no problems (as long as the pickups were adjusted correctly).

Nigel

©Nigel C. Phillips

1 guest and 0 members have just viewed this.