Granby Junction 1948 N. Wales

Posted

Full Member

GWR/LMS OO Gauge DCC RR&Co

[user=1814]Longchap[/user] wrote:Hi John,

Good to see your shed almost back in business and great to hear of the excellent performane of the new Fleischmann TT. I'm looking forward to the day I can build my own TT module and get it up and running, it being a brass kit with Locomotech electronics and indexing.

All the best with the remaing painting, ballasting and weathering. Tedious I know, but so worth the effort when complete, so bon courage as we say over here.

Looking forward to your next weekly post.

Best,

Bill

Hi Bill

Thnks for the comments. Your turntable project looks interesting but beyond my skill level I am afraid. Having admired your coach conversion I suspect it will be a breeze for you…….but probably a winter job….you must be super busy right now.

I like your optimism about “ my next weekly report ….but i will try!

Best wishes

John

Posted

Full Member

Yep, super busy indeed with 5 clients at the moment and both cottages fully booked until August, so unfortunately no more modelling until at least September, but nothing serious until the the winter :sad:

The new race car is however a welcome distraction with a big event next month :cool:

I hope the new window film works wonders with heat control in the railway room. I'm insulating the workshop roof next week to help keep the heat in during winter!

Enjoy the summer,

Best,

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

Its a very robust piece of kit……I have seen it described as bullet proof.

Sadly I now know its not ballast proof…………if a careless clumsy geriatric knocks over an open jar of ballast tipping the entire contents into the well of the turntable. :It's a no no

During the last three weeks I have become very familiar with this

The underside of the bridge.

On the left is the motor sub assembly which is technically ingenious but with a whiff of Heath Robinson.

On the right the more sophisticated control board with a multi contact slip ring.

I have replaced the control board and I am now an expert on stripping and assembling the motor unit.

After two weeks of anguish and head banging

Everything appears to work again:Happy

So its back to this:

Note the firmly attached screw cap!

But its not allowed near the turntable

Unless the turntable is properly dressed

Relieved in Vancouver

John

Posted

Inactive Member

Remember to remove the conductive turntable cover before switching on the Lenz. :lol:

Max

Port Elderley

Port Elderley

Posted

Full Member

Thanks Max……hope the house move goes well

Posted

Inactive Member

Max

Port Elderley

Port Elderley

Posted

Full Member

Glad to hear that the turntable is ballast proof and has survived the attack of the grit !!

Your last photo raises all sorts of possibilities for future layout designs that incorporate a hot plate - I'm imagining a layout where you can entertain guests with an impeccable schedule of trains intermingled with satay chicken, etc cooked at the turntable kitchen :cool: :cool:

Now where did I put that wine glass - ah there it is right next the ballast jar …..

Posted

Full Member

Hi John,

Glad to hear that the turntable is ballast proof and has survived the attack of the grit !!

Your last photo raises all sorts of possibilities for future layout designs that incorporate a hot plate - I'm imagining a layout where you can entertain guests with an impeccable schedule of trains intermingled with satay chicken, etc cooked at the turntable kitchen :cool: :cool:

Now where did I put that wine glass - ah there it is right next the ballast jar …..

How on earth did I miss this……..my apologies Dave :oops: I guess summer and the World Cup got in the way……..

Despite the lack of updates I have actually been making slow but steady progress and the Wok lid has been returned to the kitchen. :lol:

In addition to replacing the turntable, I wanted to replace the 3 way point at the entrance to the shed and generally improve the running reliability up to the turntable

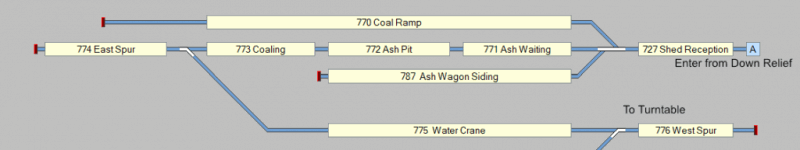

This is a screenshot of part of the RR&Co switchboard.

This is the sequence locos follow when coming on shed……….

Locos pause briefly at 727 Reception before moving on to 771 Ash Pit and then to the Coaling stage and then on to the East Spur

The point is thrown and the loco stops at the water crane then eases forward allowing any following loco to advance to the crane. From the water crane, locos move to the west spur and await their turn on to the turntable. (omitted from the screen shot for clarity)

You will be relieved to hear there is a more direct route to exit the shed! But I must admit it is a pretty tortuous way to get to the the sheds. If I were planning it again I might attempt something different……..but for all its faults I have managed to squeeze a quart into a pint pot……………..I would be delighted if someone could point be to something on the prototype that was even vaguely similar.

With this routine I have had up to 5 locos all shuffling round at the same time on their way to the turntable………..very satisfying until they got to the three way and then far too often promptly derailed

So the three way has gone replaced by a standard medium radius and the ash wagon siding (which never worked) now runs off the reception road and is operational

The two roads of coal wagons by the window are not on the screen shot. They are part hidden storage yards for the long mineral trains that crawl (full and empty) through the branch ……….part of this project is to make them fully hidden and cover the window sill with some industrial buildings…..but that will be while yet..

The next road is the coal ramp…..block 770 followed by the re aligned ash pit waiting line and ash pit with the ash wagon siding along side.

The East spur is not in the shot but the route to the West Spur can be seen running past the turntable which is just being entered by an unidentified Castle.

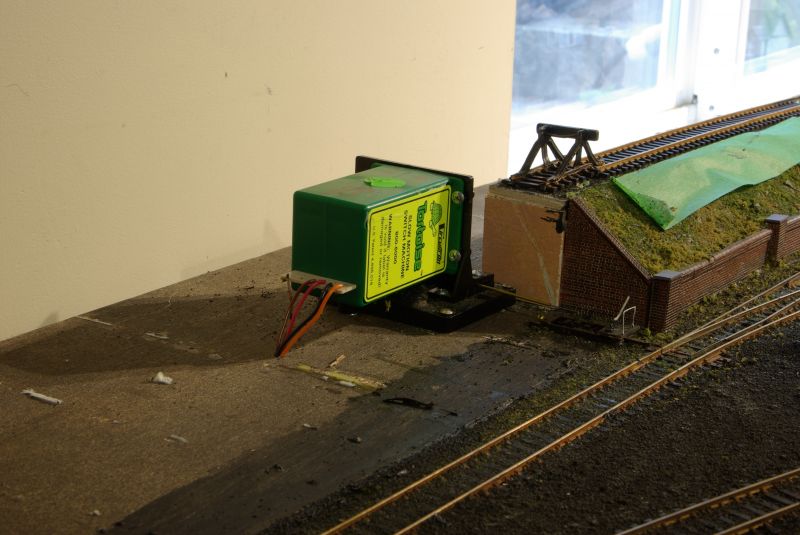

I had hoped to retain one of the tortoi that powered the 3 way point but it was not to be. This shows the Cobalt SS surface mounted motor that I had to squeeze in.

I have always had problems with this area………the storage yard boards on the left side of the room are 2.5" higher than the main line station boards (please dont ask) and the shed boards were added years later. This is where the three examples of my rough carpentry meet :shock: :shock: Is it any wonder I had running problems?

I really should have taken them to the tip and started again……..too late now. I have spent far too long trying to make a silk purse out of a sow's ear. There are some unrealistic level changes and the clearances are sometimes a bit tight………..having said that I have tested the track with assorted locos…..big and small….. and it does seem to work………no derailments and generally smoother running.

So on with the painting, ballasting , grassing and weathering

Including some of the turntable………..here is a reminder of how it used to look

Concrete surrounds and wood surround planking weathered. Top right has been bedded in with grass and ballast. Nothing on the left yet as the water crane and a small hut have to be installed and I need to work out how the dummy exit tracks should be stop blocked. The bridge has had some temporary camouflage while I ponder on a more permanent solution. Bridge green house removed and wasp stripes painted grey, planking painted but still to be weathered.

My apologies again for the sporadic updates

Progressing in Vancouver

John

Posted

Site staff

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

Yes and No!

The wiring is a breeze and they have corrected that initial problem with position memory.

Lining them up and then adjusting the throw is very very fiddly………particularly in this case because of the narrow space and level variation. I had a few false starts but they are finally working consistently.

Have you tried them?

Best wishes

John

Posted

Site staff

No, I haven't John - if I rebuilt my layout, then they would be considered.Hi Ron

Have you tried them?

Best wishes

John

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Site staff

Regards

Alan

Born beside the mighty GWR.

Alan

Born beside the mighty GWR.

Posted

Full Member

Thanks Alan………..I just wish I had used it from the start! Fortunately its job is done……its now back in the kitchen!Love the Wok cover John,it seems a perfect fit. :thumbs

Thank you for the header picture…….it certainly captures the muck and mess of this project :roll: :lol:

Cheers

John

Posted

Full Member

Phil

Posted

Full Member

Hi PhilExpensive piece of kit John, but if it does the job, all well and good…when will you be extending that room/building

Yes it was definitely a major purchase……I had to think long and hard before replacing the Heljan…..and that wasnt cheap.

So far it works very well……the indexing is very precise and consistent and it talks to RR&Co which was the main reason for changing. There are a few minor issues to sort but all in all I am very content

I am afraid Granby has finite boundaries and I have reached them! Like many North American layouts its in the basement of our house…….there is bit of space at the end of the room that I use as an office but its not really feasible to use it for a layout extension because there are doors on either side.

There is a room next door (you can see the entrance on shots with the Tv) but I blinked and Mrs D annexed it into her empire as a sewing room.

Cheers

John

Posted

Full Member

Posted

Full Member

Many thanks for the informative update. You have made good progress - in fact your efforts put mine to shame

When you have have it completed you must take a video so that we can see it all in action.

Best wishes

Last edit: by gdaysydney

Last edit: by gdaysydney

Posted

Full Member

Hi John. Been following the thread with interest especially the recent stuff on the turntable replacement project as I am also planning to use RR&Co. Although my layout is still at the basic track laying stage I am always trying to plan what's on my to-do list one item of which is sourcing a turntable. Various sites show the width of cut-out required but none show the depth. Any chance you could give me some idea as my layout has a fiddle yard directly underneath the scenic board where I was planning to site the turntable. If all else fails I may I have to relocate it to nearer one of my stations where there is nothing underneath and any change of location would be good before I get to that point. I have to say with 30+ deg temperatures upstairs, work on the layout is somewhat slower than planned.

Hi Dave

Glad you find my ramblings of interest.

I just went down to the railway room to check the TT depth……its difficult to get a precise measurement because of its location. Its sunk into a 3/4†baseboard and very little protudes underneath. Other than the cable I would estimate that the overall depth is a little more than 1†in total……ie including the baseboard depth.

As you will have gathered I initially installed a Heljan/Walthers TT……….its not directly supported by RR&Co but can be made to operate without purchasing a decoder (unlike the Fleischmann ). However after many attempts I found it too inconsistent for intensive automatic operation although manually it was generally effective……hence the great upheaval.

Fleischmann is supported by RR&Co but you do need to buy a decoder just to operate with DCC. I bought Fleischmann’s proprietary “Turn Control†which is excellent…..does exactly what it say on the label……but there are less expensive alternatives. LDT (?) is quite widely used with the Fleischmann…..I understand its cumbersome to set up,unlike Turn Control which is a breeze, but once set up isvery effective

So far I have found that Turn Control interfaces very smoothly with Train Controller……no issues with loco facing the wrong way etc……..there are a few minor niggles I have to work through but overall its great….I just have to drag myself away from the construction and write a few schedules!

Hope this helps…..let me know if you need any more info

Cheers

John

Posted

Full Member

Hi John,

Many thanks for the informative update. You have made good progress - in fact your efforts put mine to shame

When you have have it completed you must take a video so that we can see it all in action.

Best wishes

Thanks Dave ……its going to be a while before all the buildings and people are back in place. As you can see in my reply to the other Dave I really need to spend some time on the computor…….once done I will try and make a video of one of the routines even though there is still modelling to finish

Best wishes

John

Posted

Full Member

Not sure if it was a coincidence but it was nice of Alan to select the turntable shot as picture of the week.

Back to the layout:

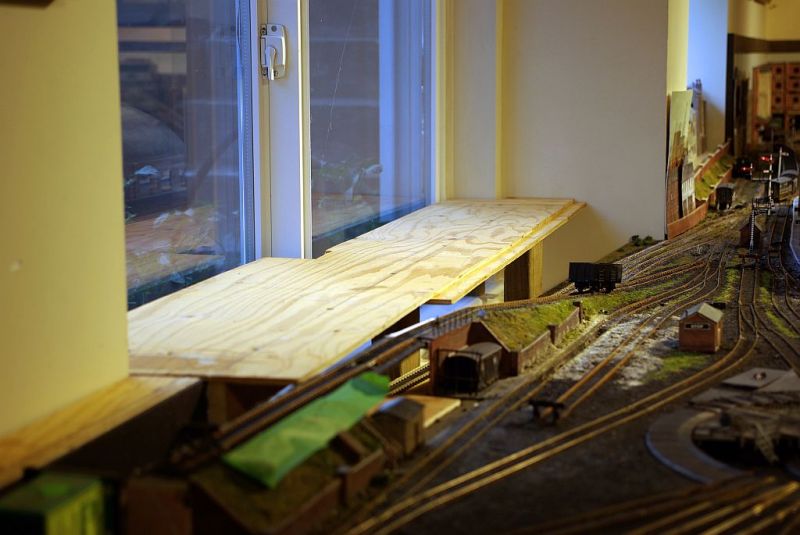

I am reluctant to start replacing buildings and engines in the shed area until this area at the back is finished

There are two issues….the undeveloped window sill at the top and the surface mounted tortoise at the front

The tortoise had to be surface mounted and remotely connected because the mineral train storage lines are immediately below. Previously I had concealed it with an extension of the coaling embankment but I want to use the space for some offices, stores and a mess room .

The tortoise will be concealed beneath two heavily modified Station Masters houses from the Scalescenes Medium Station

Its not a typical GWR structure….not sure they had two storey mess/office buildings on a medium sized shed but you can see why I need the height. Fortunately John Wiffen uses this Dutch Gable feature in a lot of his kits including the small engine shed. Ths kit provided the entrances to the six bays of the roundhouse, so.hopefully, it will look as though it is all of a piece .

Lots still to do……meantime on to the window sill

I have been putting off dealing with it for ages hence the assorted vignettes of the vegetable garden that appear at the back of the coaling ramp.

A piece of fine carpentry will act as a foundation

A couple of long serving buildings plonked in position to see what it will look like

The idea is to create sub units …..a street scene, the old brewery etc each of which can be accessed separately for detailing and dusting……..I am working on a 4' pole with a hook for the end unit!.

I keep looking at that Coaling Ramp and wondering if a Kernow 1361 could climb up it ……..I am very tempted, even though they never ventured into North Wales.

Regards from Vancouver

John

1 guest and 0 members have just viewed this.