Going Small with a GWR Branchline 1890-1920

Posted

Full Member

GWR Branchline in EM Gauge 4mm Scale

The transfer says ex-GWR, the packet says GWR MINK. The kit contains the bits to model the early phase of the vans as well as the later ones under GWR ownership. It is a GWR kit without GWR transfers. And it clearly states transfers included. Which they definitely are not. Just putting BR transfers in the kit is…cheap.As much as I would like a BEETLE, no evidence that these rare beasts got anywhere near the branch!ine. Actually no, I remember building a Parkside one many years ago. Correct brown plastic, painting not required. My notes say it was a PITA to assemble. Just like the MINK. The tooling is quite inaccurate, fettle here, fettle there, repeat.

Nigel

©Nigel C. Phillips

Posted

Full Member

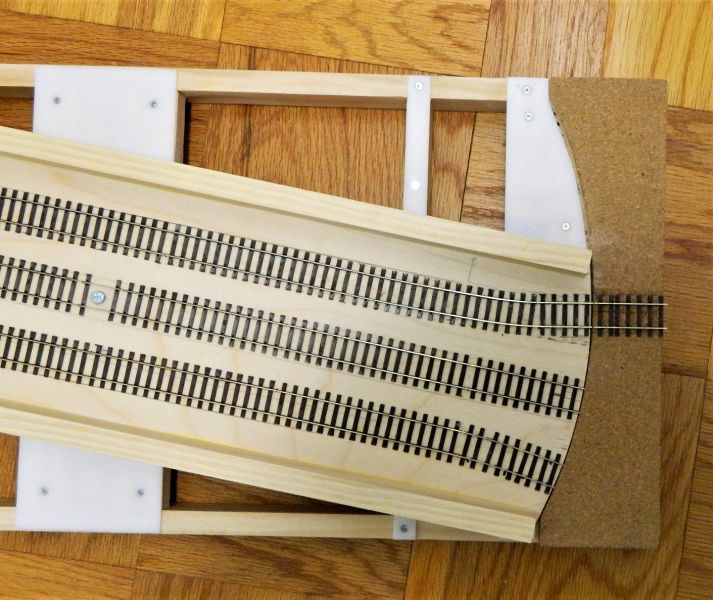

Track laying has started. Scaleway EM gauge code 75 flex track (which I have several hundred feet of, thanks to an online gift from somebody leaving the hobby).The sector plate now has 3 tracks, plenty of room for fingers from the sky. I tested some stock through the curves and over the pivot bolt in the middle. Seems OK. Next will be wiring and some stock transfer sections (think level crossing) so stock can be simply slide on without worrying about "are the wheels on the rails".

Nigel

.

©Nigel C. Phillips

Posted

Full Member

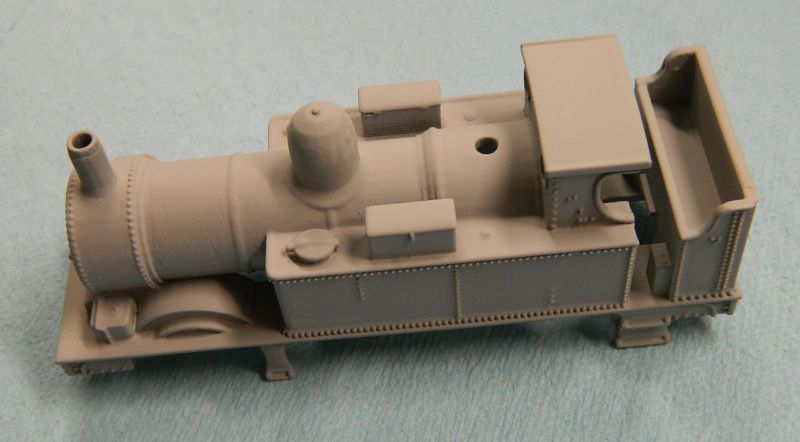

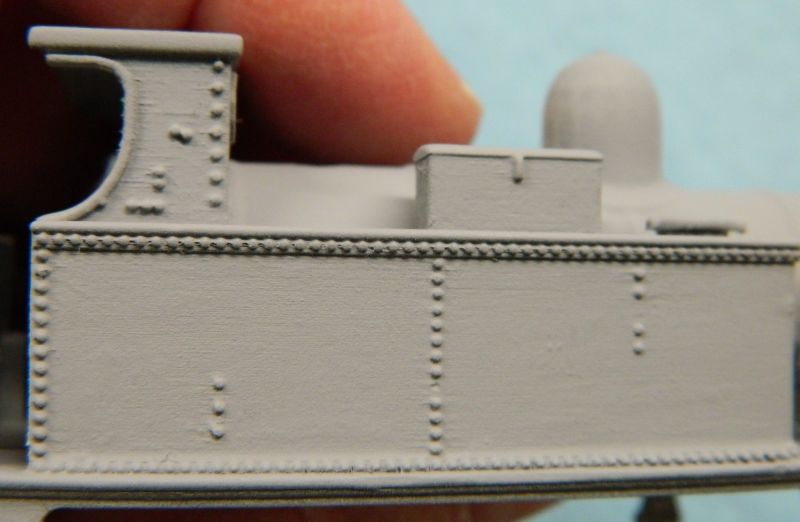

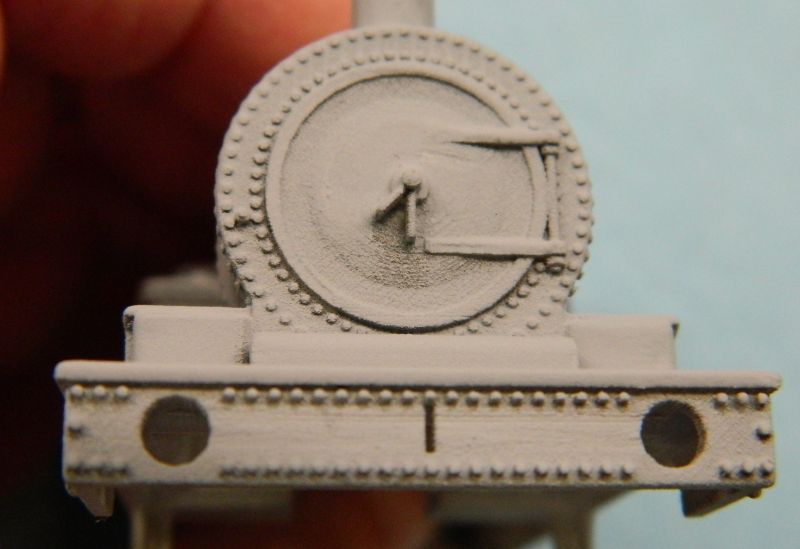

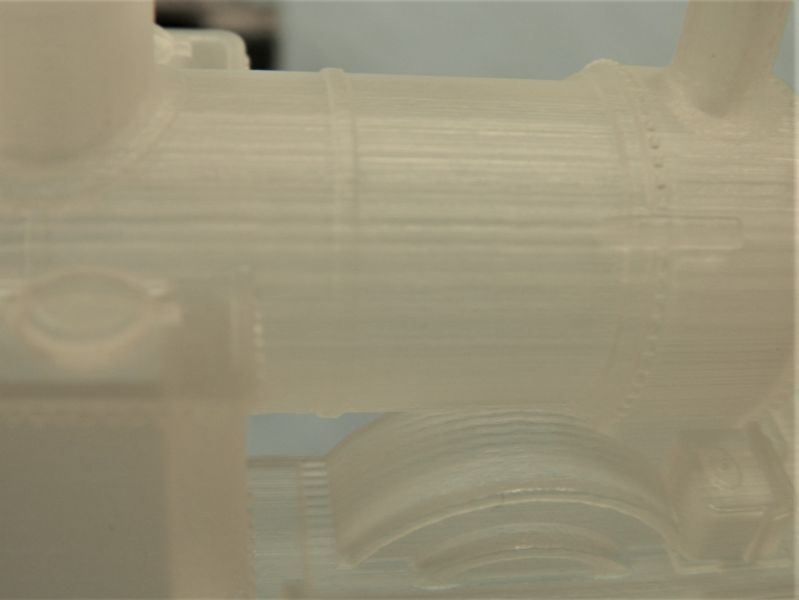

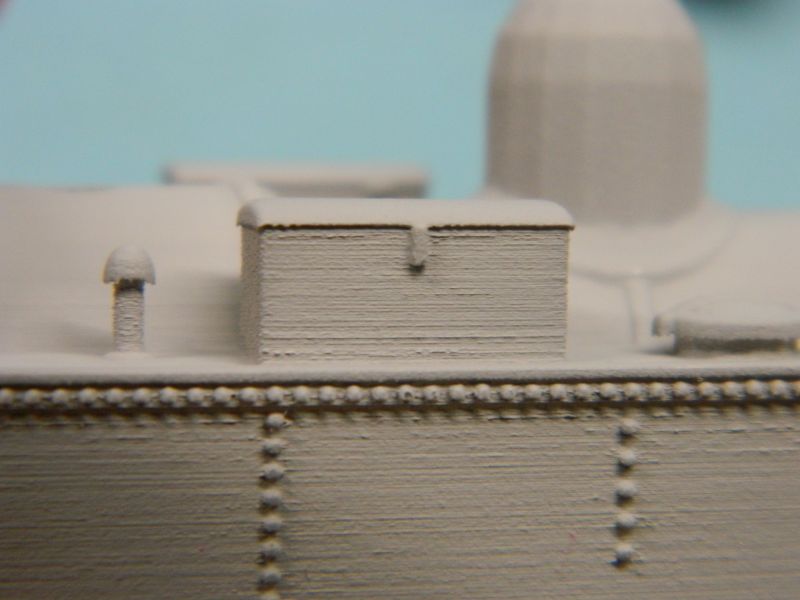

Second look at the 517 metro tank. Couple of hours of fettle, fettle, coat of grey filling primer this time. Better than it was, still not 100% perfect, but goodenuff I think given that it will get quite weathered, along with a few dents and dings appropriate for a 40 year old workhorse. Still not happy with the dome, it will probably go and be replaced with a metal one. I have some in the spares. The air vents for the tanks came off during fettling, again, I have some spares.

The last photo is the new replacement. Those ridges are what happens when the printer tries to do a vertical curve. Sides and back feel much better, no way to really tell until it gets a coat of primer. Bit too cold to go rattle canning at the moment, tomorrow should be better.

GWR 1900's green paint. In North America. Ha! Good luck says the layabouts (Bodgit, Fudgit and Wingit)

Nigel

©Nigel C. Phillips

Posted

Full Member

Quite a long post today, but I thought it might be of interest to fellow modelers.

Now that some wagons kits are rolling off the production line it's perhaps time to think about what goods traffic could have been carried by the branch line in the time-frame I’m modeling. Rather than just getting a random selection of GWR and PO vans and wagons I decided a more reasoned approach was called for. Most of us do not have access to the goods traffic receipts (especially from 3000 miles away and 110 years ago), so reference to what was happening business-wise in the village or town that was served by the line is a useful tool. The town in question is Watlington, Oxfordshire, the GWR engine shed there was a sub-shed of Slough, London Division, where locomotives were sent once a week for a boiler washout. Watlington-Princes Risborough-High Wycombe-Maidenhead-Slough was not far, and apart from the Risborough-High Wycombe section was on secondary lines. Banbury was more direct but in the Worcester Division and on the main line, Oxford was closer and in the London Division, but Slough it was to be for the life of the line.

I've been using Kelly's Directory of Oxfordshire 1907 and Kelley’s Directory of Berkshire, Bucks and Oxon 1911, various editions of The Engineer from 1900-1910 (accessed through Grace’s Guide, mainly for information on gas works), plus the usual reference books on the Watlington branch line, to get some idea of what was happening back at the beginning of the 20th century. The directories especially are very useful sources of information, right down the number of bells in the church and when they were installed or the number of public houses and hotels. Many are available online for free, and make interesting reading.

In 1907 this microcosm of Edwardian life was inhabited by some 1550 individuals. And it did have a butcher, a baker and probably a candlestick maker. And a bank, a brewery, 2 doctors, a cottage hospital, and several schools, both public and private, What I have come up with is as follows:

General parcels traffic. The G.W. Railway parcels agent was to be found in town at the Hare and Hounds Hotel, “an omnibus meeting all trainsâ€. A passenger brake van was usually rostered in all passenger trains, but more importantly 2 vans carried parcels and larger items too small for a wagon or van on good trains, one from London the other from Oxford on the 2 daily goods. One interesting snippet I came across was that the average load in a van was around 4 tons, even although it was rated for 8-10 tons. One of the contentious issues around the common carrier legislation the railway companies were saddled with. Presumably the vans were sorted at Oxford then on to Princes Risborough. Mail order was big business for small country towns, both commercial and residential. It looks like I need an omnibus in the station yard, one horse power, passengers and parcels for the conveyance of. Plus, a general carter for larger items, as there were several such businesses in the town.

Crops. The main crops grown around the town were wheat, oats, barley, beans and roots (beets, mangles and the like), plus one individual who grew watercress. The town had a “chemical manure†manufacturer, so vans of the recently developed superphosphates in sacks from Suffolk via the Great Eastern Railway using GE or PO vans and opens would be logical. Traffic out? Supplies for the GWR provender store at Didcot in open wagons (hay and beans were major commodities for the GWR provender store, and a lot of it was produced by the farms around Watlington), watercress in ventilated vans in the summer, beets in the fall. All these crops of course mean agricultural equipment coming in on flat wagons. So, one of the large Provender wagons (a rare beast) and some large open and sheeted wagons for the hay and beans as well as an early MACAW are on the list.

Livestock. Lambs front Kent and sheep from the Scottish borders (prized for their mutton), and cattle to the several livestock dealers based in town. Livestock wagons got around a lot, so some models from railway companies other than the GWR would not be out of place. I haven’t done a lot of reading on this yet, but even if livestock was coming down from Scotland it is just as likely to arrive in another company’s cattle wagon (GN, L&Y, LNWR) as they would have been stopped at regular intervals to allow feeding and watering (lairage). One thing I noticed in my reading was the sheer volume of cattle and sheep imports from the continent, Ireland and Canada during the early years of the 20th century, as well as the number of large-scale lairage depots throughout the UK. There was a game farm just outside of the town (Greenfield Game Farm) from where pheasant chicks and eggs were shipped as far away as the Yorkshire moors. Not sure whether that would be a ventilated van or a SIPHON, or even the brake van. I suspect the latter, so some poultry crates on the platform will be required.

Beer. For 1500-odd inhabitants there were a lot of establishments selling beer, wine and spirits (18 in total in 1907). The town had a small brewery and malting, although one large malting had closed in the 1850’s and the building was used as the town meeting hall, capacity 600. So, barley grain out, sacks of malt and hops in. Good excuse for one of the railway companies that served the hop fields of Kent or Suffolk. The GWR was transporting beer during the time frame I’m modeling, in both barrels and bottles, so maybe some Burton IPA was coming in from the Midlands. That would explain a Midland Railway and London North Western Railway ventilated van coming in on a regular basis – both served Burton-on-Trent.

Milk. Until the advent of road tanker transport in the 1920’s-1930’s, milk was shipped out of Watlington in large milk churns using one or two 4- or 6-wheel SIPHONs at the back of the passenger trains, destination Kensington and London. Even a small SIPHON held a lot of churns (around 40-60 17-gallon conical churns) so two SIPHONS would be a minimum of 600-700 gallons a day. Double that if the SIPHONS had 2 layers of churns. The traffic at Watlington was such that the GWR built a platform extension in the late 1920’s just to accommodate it.

Coal. The Gas and Electric Lighting Companies' Directory and Statistics of 1899 reported that the town gas works was founded in 1893 and supplied 86 customers. Coal carbonized was 140, presumably tons That’s only 14-18 wagon loads, 3 wagons every 2 months. Gas produced was reported as 1.3M feet. The coal used would have been cannel coal (soft, oily, bituminous, and high in hydrogen content), often supplied from the Lancashire coal fields. Prior to the rush to build branch lines in the mid- to late-19th century this was carried by barge to the nearest canal or river wharf. The gas works was built after the branch line, which would have provided the means to ship coal in, byproducts out. So, some Lancashire colliery PO coal wagons. The Directory states that the railway used was the SW. Probably a typo, as the LSWR railway got nowhere near the town. Coming via the LNWR railway makes more sense, as coal wagons could have been taken as far as Leamington Spa and then on by the GWR. There would also have been replacement parts for the gas works (retorts, scrubbers) coming from manufacturers as far as Stourbridge to Lincoln. Plus, chemicals such as iron oxide (used to remove sulfur from the gas) coming from “up northâ€. A byproduct of gas production was coal tar, a valuable commodity, the nearest tar distillery was in Banbury (The Midland Tar Distillery), so , a few barrels a week or month would be logical. Coal tar was shipped from Oxford Gas Works by barge to Banbury, so barrels of tar on a 4-plank wagon or in a small rectangular tanker wagon will be making an appearance. Information on these old gas works is not that great, I have used the article on the gas works in Fairford, Glos., published by the Fairford Historical Society, as a source of general information. The coke generated in gas works was usually used in the works or sold locally being unsuitable for metallurgic work. The iron sulfide generated was also useful for sulfur and sulfuric acid production, so sacks or barrels out in sheeted wagons. Unfortunately, small gas works used to bury the waste, the consequences of which are still being dealt with today. Avoid any new property on a street called “Gasworks Laneâ€!

In addition to the gas works, regular coal from closer to home would be coming in for domestic and business use (in fact it was the major product coming in on the line at this time). The nearest coal fields would have been the East and West Midlands, so there will be some PO wagons from there. Anthracite seems to have come from South Wales. Loco coal would have also have been coming in GWR wagons from Wales. There was a coal merchant and agent in the station yard, head office at Goring, plus several other coal merchants in the town, so why not throw some of their PO coal wagons into the mix (no evidence that this happened, but the wagons for the Goring-based merchant are available as RTR models. Rule 1 applies here).

One anecdote I would like to “borrow†concerns one of the local estate owners down the line at the next station – Aston Rowant. A personal saloon car booked all the way to London was added to the local train at Princes Risborough. No mixing with the hoi pollois for her ladyship or waiting in the cold for the express. These cars could be hired on the GWR and went anywhere there was a railway line (Thurso to St. Ives), servants in attendance. So, there will be a saloon car visiting when required.

A note on vans. The GWR had by this time made a lot of goods vans with iron bodies – the iron MINKS. Fitted or unfitted, there were some 4,000 of them running on the GWR (as well as many on other railway companies), so the these will definitely outnumber the wood MINK vans. Luckily Ratio do a fairly decent model kit, and other variations are also available (Gunpowder vans for example)..

So, what do I have so far for the layout’s freight requirements? GWR iron MINKS, GWR wood MINKS, other railway company and PO vans, GWR SIPHONS (4 and 6 wheel), 2- to 5-plank open wagons (GWR and PO coal), GWR Provender wagon, GWR LOCO coal wagons, MACAW (flat), CROCODILE (well), cattle and sheep wagons, and rectangular tank wagon. Apart from the GWR vans I will only need 1 or 2 examples of each of the others. If I follow the prototype (and the track plan is almost to scale) I will have some fairly tight limits on what I can run, dictated by the run around and siding lengths. For a 517-class locomotive on the line the load limits were 7 coal wagons,10 vans or 14 empties for up workings. So, for mixed traffic workings 5 coal wagons and 7 vans plus the brake van, or 3 coal wagons, 6 vans, and 2 empties and the brake van, or various ratios thereof (1 coal wagon = 1.4 vans = 2 empties). This has implications for the length of track on the fiddle yard/cassette storage board. Something I will need to reevaluate.

Readers may have gathered that this an exercise in building a feasible storyline (a storyboard in essence for what is a media display) for operations on the branch line, and making sure that it is realistic for the 1900’s, and that those “what if buys†are kept to a sensible minimum. They will happen of course, nobody is perfect. We all like a bit of “shinyâ€. Passenger requirements have also been evaluated, much simpler. I will deal with those in a separate post.

©Nigel C. Phillips

Posted

Full Member

This really is a wonderful piece of research and my hat comes off to you for making the effort rather than doing what most do - run what you like. Whilst I do not claim to have any particular expertise, I have a couple of questions and observations.

Whilst vans and wagons were usually loaded through to a destination where possible, with small part-loads I am guessing that the multiplicity of vans you mention refer to loads travelling in different directions and therefore to different goods transit facilities. Banbury or Oxford (more likely) would see the vans unloaded and reloaded for east or west-bound trains. I believe that traffic was separated at source rather than all put in together to be sorted later. This implies that Oxford depot would sort out a van carrying westbound traffic by unloading and reloading into vans destined for the various depots in the west and likewise for the eastbound traffic.

I think I'm right in saying that coal wagons from pits usually went to larger end uses whilst domestic coal arrived in coal trader wagons so it would be rare to find a colliery wagon at the coal staithes with its contents being sold by the local merchant. You may get some at a factory if demand was sufficient to allow them to buy it straight from the pit. WARNING - this relationship betwen colliery, trader and merchant is a vague memory of something I looked into a long time ago so I may have got this wrong but there are books (Bill Hudson is one noted expert) explaining how it worked and well worth seeking out.

At the start of the 20th century, I wonder if small town pubs imported much ale or just relied on the local brewery. I discovered that by the 1920's, Bass, Worthington and Guiness were the "only major breweries to have a national distribution network" [Wikipedia so make what you will]. That suggests that your imported ale would probable come from one of these 3.

Having said all the above, there is plenty of photographic support for traffic flows, especially along GWR branches which dominated modeller's attention in the 1970's and 1980's. If you are like me, a photo of something you like running close to/in the geographic location of your layout is fair game to run on your layout!!

Thanks for sharing your research - very much a prod to those of us prepared to run what we like!!

Barry

Shed dweller, Softie Southerner and Meglomaniac

Posted

Full Member

Thank you for taking the time to post the results of your research.

Best wishes

John

Posted

Full Member

Vans and sorting. Two parcel vans, one from Oxford, one from London. Logically they would have been shunted around at Risborough, which had a fairly large yard, as it was also the terminus of the Thame branch. London to Oxford, then on to Risborough. As far as I can determine what ran on the line at this time was shunted veforehand.

I did a fair amount of research on coal factors, as nice as a rake of various colliery wagons is it didn't happen on lines that had low traffic. A local coal factor would have been contracted, and their wagons would be the ones used. That said, various sources state specific colliery sources, so the odd one will creep in. Many local coal merchants leased a few wagons painted in their colors that would transport coal to their yards, good publicity.

Bass it will be, as the distribution system was well established, and there was a market for highly hopped bitters.

The aim here is to get some sense of what ran on the line or could have ran. The coal tar was as likely to be used as creosote rather than being sent to the local distillery.

Nigel

©Nigel C. Phillips

Posted

Full Member

..and your layout will look better for the accuracy of the traffic

Barry

Shed dweller, Softie Southerner and Meglomaniac

Posted

Full Member

Spent a couple of hours going over old photos of GWR freight trains around Oxfordshire in the 1900's. Fair number of colliery wagons (even some dumb-buffered) as well as coal merchant and factor wagons. Seems one colliery from North Wales had a steady business supplying cannel coal to many of the gas works in the county. Probably too specialized for the merchants who would be going for the much bigger domestic market. Plus cattle wagons from the North East to the South East.

Nigel

©Nigel C. Phillips

Posted

Full Member

Hi John,Fascinating. That was a thoroughly enjoyable and informative read.

Thank you for taking the time to post the results of your research.

Best wishes

John

Thanks does The kind comment.

Nigel

©Nigel C. Phillips

Posted

Full Member

Just a short note on cannel coal and gas lighting. I finally located a source of information regarding cannel coal dating back to 1918 - "Cannel Coal in the United States, George H. Ashley, United States Geological Survey Bulletin 659, 1918". Produced as a review of the production of gas, chemicals and fuel oil from coal as a result of war-time shortages, but full of useful information not only on US cannel coal, but also cannel coal from the UK. The bulletin is available online for those interested.

Gas works throughout the UK prior to the late 1880's would have been using cannel coal rather than regular coal as it gave more gas per ton, had a better light output (luminescence), and had more thermal capacity for cooking than gas produced using regular coal. It also gives double the amount of oil after distillation of the tar (hence the US government interest in a domestic source of fuel oil). There was a reason behind this, regular coal comes from peat bogs, cannel coal comes from lagoons and has a very high content of spores and pollen plus animal remains. After formation of coal this results in a high available hydrogen content (often as much as 10%) as well as a high content of carbon in the form of organic volatile compounds which when burnt gave the luminescence. Ideal for lighting with a naked flame. Not so good for coke production, as it was very crumbly. The production of high luminosity gas depends on the temperature of carbonization in the retort (and the skill of the gasworks operators). Higher temperatures gave much more gas but less volatile compounds and less tar, good for cooking but not lighting. The use of gas was changing also with the advent of electric lights. Municipal street lighting was often the major use of coal gas.

Cannel coal is commonly found in small deposits (ancient lagoons, ox-bow lakes or slow moving river beds), on top or beneath regular coal deposits. Supplies in the UK were getting exhausted by the turn of the 19th century, and it was consequently an expensive material compared to regular coal. The gas mantle was invented in the late 1880's, and spread rapidly. The luminescence with a gas mantle comes from heating the mesh of rare-earth metal oxides, not from the carbon-content of the gas. And could therefore use the much less expensive coal gas coming from regular coal.

So what has this got to do with the branch line I'm modeling? Some more research showed that in the early part of the 20th century coal from the Wynnstay colliery was coming down from Ruabon (Rhiwabon) to gasworks in Oxfordshire and Berkshire in colliery wagons. Ruabon is located in the Denbighshire coal field, which has distinct seams of cannel coal and gas coal, so some colliery wagons from this area will be making an appearance on both the gasworks coal and domestic coal train runs (Wynnstay Colliery or or one of the other collieries in the area such as Ruabon Coal and Coke Co. Ltd, where Sir. Daniel Gooch had been instrumental in founding the company and was a major investor. The other GWR connection is that Sir.Watkin Williams-Wynn, owner of the estate which leased the land to the Wynnstay Colliery Company, was a director of the GWR, which had good railway connections from the Ruabon area to Oxfordshire.

Nigel

(Cannel coal is also formed into jewelry - Jet).

Last edit: by spurno

Last edit: by spurno

©Nigel C. Phillips

Posted

Full Member

I give up! Replacement 517 3D print body shell came from Shapeways. I gave it a quick spray with grey primer in order to see the extent of fwttling that would be required. So….

Time to rethink the strategy on this one. Two choices: Conversion of the old K's 14xx white metal body shell to a 517 one; Get a body kit from SE Finecast to go with the 517 chassis. I originally went with the 3D print body shell to save some time. Adding up the hours spent on the first one just fettling out those print ridges I could have built 3 kit ones.

Shapeways to their credit gave me a credit. Methinks all those rivets play havoc with the actual print process. What looks good on the 3D CAD doesn't actually translate into a good 3D print. Second shot shows the ridges from the 3D print layering. Not sure I want to spend another 15-20 hours getting rid of them.

Nigel

©Nigel C. Phillips

Posted

Site staff

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

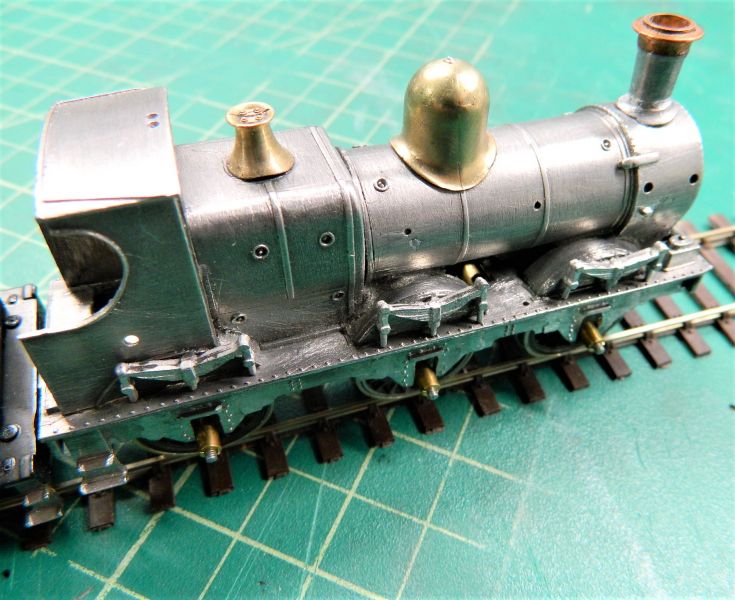

Springy thingy time. I ordered some white metal leaf springs from SE Finecast late last year, time to put them on the 0-6-0 outside frame Armstrong goods (loco and tender). It now looks a bit more late Victorian. Some outside cranks whirring around with will definitely finish the chassis off. That safety valve fixture looks like it's from a round firebox, should have a Belpaire flat bottomed one somewhere. The tender is a much abused 2500 gallon one from a Bachmann City class. Too much trouble getting wheel sets off and on the K's white metal lump that came with the kit. This tender comes with insulated split axles and electrical pickup off 4 wheels.All regauged to EM standards.

Nigel

©Nigel C. Phillips

Posted

Full Member

The eye seems to be amazingly sensitive to this aspect of resolution so a Modelu character can look superb yet a "smooth" surface look like sandpaper.

Colin

Posted

Full Member

Best,

Bill

(who is actually enjoying the enforced peace and quiet of the compulsory lockdown here, fortunately aided by a sufficiency of stock in the wine cellar and a return of warm sunny days)

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

I actually think the current iteration of the technology (thermoplastic polymer) has reached it's limit. The high end polymers push a 3D print into highly detailed brass or white metal price territory. The surface can be got acceptable, but at considerable cost in time. The advantage of course is that the body shell is complete. All that rivet detail is a good idea that turns out not to be so in practice.

Just ask the question - would you accept that body finish from Hornby, Bachmann , or any other RTR supplier?

White metal kit is on order. Nuff said.

Nigel

©Nigel C. Phillips

Posted

Full Member

Thanks. It's getting there. Lot's of challenges in going Victorian/Edwardian. Especially on a branchline.

Nigel

©Nigel C. Phillips

Posted

Full Member

Hi Nigel,Hi all,

Just a short note on cannel coal and gas lighting.

Still watching, do keep it up. I feel for you with the 3d fettling….

I have recently read an artcile in a 2016 Great Wester Journal talking of the manufacture and distribution of gas for coach lighting. It refers to Swindon Gas Works around 1900, seems shale [Gas] oil from Scotland was used, transported in ordinary GWR 3000 gallon tanks because it is a low flash point [not 'Class A'] product and refined at GWR gas works before being moved about the system in 'Cordon' wagons. It was also used commercially to enrich coal gas. It's worth noting that long after it ceased to be used for coach lighting for passenger safety reasons it was used for restaurant cars and horse boxes!

Should you want to know more, I'd be pleased to scan and p.m. the 3 page article.

Best wishes,

Douglas

Last edit: by spurno

Last edit: by spurno

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

Yes, I'd appreciate a copy. Apart from the spare carriage, stored in the shed, as far as I can determine no carriage was ever stored at Watlington, so no Cordon a-visiting. Presumably this was done at 'Risborough. Although that spare would have needed topping up.So just maybe…(it's on the list).

The shale referred to is Cannel coal. The volatile gases would have been already taken out, what they must have been doing at Swindon was cracking it down further to carbon-rich gas with high temperatures (oil carbonization). Used as an adjunct to regular coal gas until the widespread use of gas mantles. Which was about 1900, so I doubt this went on much longer. I knew about the use of gas in restaurant cars, having built a model of the Centenary restaurant car a few years ago. Five long cylinders strapped crosswise underneath and used for cooking (electric lights though, dynamo equipped when built). The one they have at Didcot has the BR Calor gas tanks following the update in 1947..Not sure whether gas was ever used in dining cars for lighting following the advent of dynamos in the 1920's and 1930's when older dining cars would have been shopped. Dynamos for passenger cars were being tested successfully by the GWR in 1906.

Nigel

©Nigel C. Phillips

1 guest and 0 members have just viewed this.