00 Gauge - Maxmill Junction

Posted

Full Member

Petermac's Railway

[user=6]Petermac[/user] wrote:Yep, I think that's fair enough. ;-)[user=1120]peterm[/user] wrote:I'm sure that whatever amount you get, they'll look good.

You have far too much unfounded faith in my abilities Peter !!

If it all goes belly up, it's down to Phil ….

Cheers Pete.

Posted

Full Member

Phil

Posted

Full Member

'Petermac

Posted

Full Member

Phil

Posted

Full Member

Bill

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

'Petermac

Posted

Full Member

Posted

Full Member

Not sure if that will continue after December 31st …….. :hmm

'Petermac

Posted

Full Member

Thinking about it is, I'm sure, much easier than actually doing the job will prove to be …………………..

I've never handled the Wills sheets but have read that they're "heavy duty" and difficult to cut. Scoring several times before "cracking" should not present too many problems for straight cuts. The arches will not be quite so easy to cut. I do have a scroll saw (powered fret saw) and wonder if this might work. Often with plastic, power tools create too much heat and tend to melt the plastic. What are your thoughts on this Phil ? Remember - I'm much better at cutting concrete blocks than delicate engraving on expensive shotguns ……………………

Also, as the viaduct is curved, I'll need to bend the parapet sheets - the pier faces are of course, not curved so should be quite easy. Will I need to soften them in hot water and clamp them to a former to induce the required curve ?

I also read that Michael (Headmaster) used Deluxe Rocket card glue to stick his plasticard timber "fret" to the card skeleton on his houses - would that hold something as tough as Wills sheets to my card backing ?

I'll need to do lots of further reading before tackling a paint job but firstly, I need to fit the sheets !!

'Petermac

Posted

Full Member

"V" file or cut with a blade, many lines to bend the sheets.

Phil

Posted

Full Member

I should have a piercing saw somewhere but fear I may have to buy a replacement - at which point, the old one will turn up !!!

Sounds like I've got a lot of cutting to do …………………..

Forgot to ask - do I just "over cut" to allow space for the edging stones on the arches ? Do the sheets have an appropriate run of stones for this purpose ………..?

'Petermac

Posted

Full Member

Make sure your saw is actually a piercing saw and not a coping saw.

Make sure your saw is actually a piercing saw and not a coping saw.All the sheets are identical so when one sheet butts up against another on a corner the stones won't match up if that's what you mean?

The edges need to be cut at 45 deg like a picture frame, then when glued, and a small file to make the groove carry on throughout……or cut a V on the back and fold as I mentioned in an earlier post, this will continue the stonework around the corner. The stonework (corners) under the bay window is folded.

Last edit: by Phil.c

Last edit: by Phil.c

Phil

Posted

Full Member

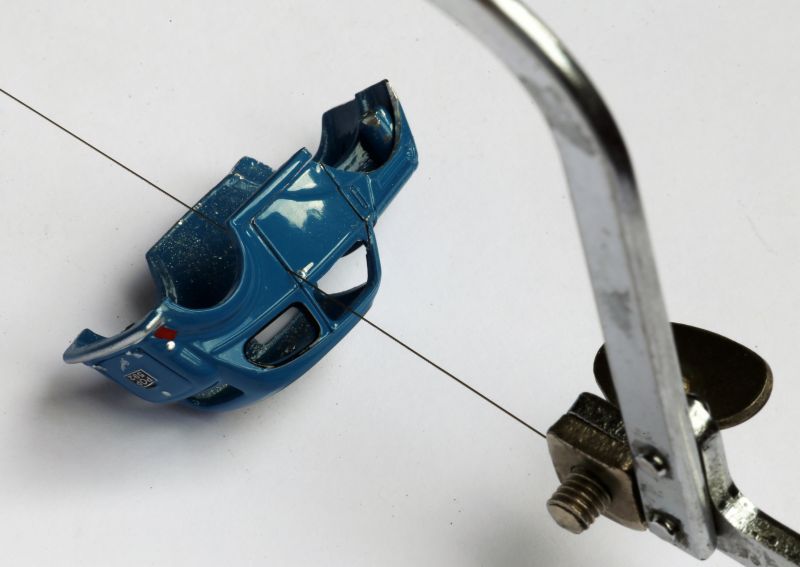

Would it be possible to post a picture of a piercing saw? North American carpentry terms sometimes differ from the UK

Bomme chance Peter!

Posted

Full Member

This is the best picture I have of the saw.

Phil

Posted

Full Member

Posted

Full Member

Hopfully Peter, you will find yours before then!

Bon courage mon ami,

Bill

Last edit: by Longchap

Last edit: by Longchap

At 6'4'', Bill is a tall chap, then again, when horizontal he is rather long and people often used to trip over him! . . . and so a nickname was born :)

Posted

Full Member

Last edit: by Phil.c

Last edit: by Phil.c

Phil

Posted

Full Member

At least I won't have to start until I've ordered a saw - anything to put off the evil day ………………….. :chicken

I can see my original idea of finishing the viaduct between breakfast and lunchtime might be pushing things a bit. I could always just have a concrete embankment …………………………………… :hmm

'Petermac

Posted

Full Member

If you remember my oast house build, that was normal Wills sheet which I softened in hot water and formed around a pipe. However, it is also glued to said pipe. I'm not sure it would keep its curve without quite a bit of help. Others who have done it would know. There is a flexible brick sheet for lining viaducts, but I don't know if you would want brick inside the viaduct.

I don't think Rocket card glue would be strong enough to keep the heavier Wills sheets to card. I've used Gorilla Wood glue, despite what people say about such glues (I presume it is a PVA) and also UHU, both of which have worked.

When I have cut curves (admittedly small ones rather than big arches) I stick a card former to the rear of the sheet and then use this as my pattern for cutting and then tidy up with a file. Wills advise drilling small holes along your line and then cut them and file. But that is a lot of drilling!

Michael

Posted

Full Member

I use this saw to cut birds, animals scroll out of gold, silver etc and very small so a viaduct wall in comparison is a piece of cake:)

Phil

1 guest and 0 members have just viewed this.