00 Gauge - Maxmill Junction

Posted

Full Member

Petermac's Railway

:doublethumb :doublethumb :doublethumb

Phil

Posted

Full Member

I'm beginning to think the moral is, don't buy used equipment unless it comes with a wiring plan and a guarantee !!! It takes me back to my experiences with locomotives on that well known auction site - for every one that worked, at least 2 didn't !!

Anyway, back to my current headaches.

Yesterday, I'd mentioned I hadn't looked under the boards on one side of the layout. Today, I corrected that situation and, looking under the first section, this picture of loveliness greeted me:

The white rectangles are holes cut in the chipboard for previous point motors (Peco, I'd guess) and the wiring presumably related to these. There is a rigid bare wire connecting most of the choc blocks - perhaps used as a common return or something.

I have removed all the wire remnants and it does look slightly tidier although I can't for the life of me, see how the power is fed to the tracks. Maybe it's just carried by the rail joiners ……………….

Some of the holes don't actually marry up with the points above so presumably, parts of the layout have been re-layed at some stage.

I have a couple of questions relating to the above picture -

I have a heap of SEEP PM1 point motors left over from the previous Maxmill but typically, the operating pins are now not long enough to pass through this (thicker) baseboard.

Not only is this baseboard thicker than my old one, but I also plan to cover these holes with 5mm ply because I can't fit SEEP motors over the holes. Any ideas about the best way to lengthen the operating pins with sufficient strength to operate the points ?

I really do want to use the SEEP motors I have - it would seem wasteful to throw them away - but additionally, Tortoise motors are in short supply in UK - maybe due to the lock-down.

Whilst I'm down on the floor, I'll add some track feeds too …………….heaven knows, it takes me long enough to get down there and even longer to get back up again !!!

'Petermac

Posted

Full Member

Michael

Posted

Full Member

I did see a shop in Halifax (I think it was) advertising them - a length of tube plus piano wire extension - enough for, I think, 3 SEEP motors for £9.99 - postage to France £16.50 !!!!!

'Petermac

Posted

Full Member

If you PM me an address, I will happily post them off - they are of no use to me.

Regards

Michael

Posted

Full Member

PM on the way. :thumbs

'Petermac

Posted

Full Member

Michael

Posted

Full Member

I did however, manage to spend an hour or so in the unit this morning waiting for last night's rainfall to evaporate.

The section I'm working on now is the main station, the opposite side of the unit to that of the storage/fiddle yards. My previous post showed the holes in the baseboards where earlier point motors had been mounted. These holes will, I think, have to be plugged before I can mount new motors but that's for another day ………….

Whilst waiting for a delivery from Headmaster, who is very kindly sending me a kit to extend the operating rods on my SEEPs, I thought I'd test and re-programme the 4 LS150s required for the station area. Previously, they had been set up to operate Tortoise motors with a pulse time of, I think, 3 seconds. This would very quickly burn out the SEEP coils. I'd read that the shortest pulse - 1/100th sec. - is sufficient for SEEP and Peco surface mounted motors so that's the pulse time I set. It works fine with no-load motors of both types. Hopefully, the load, once attached to the points, won't make any difference …………….. At the same time, I reset the addresses to match this new installation.

The station throat at the "south" end has 9 points, all of which will be changed from insulfrog to electrofrog, most of which I already have in stock. Here are some of the points to be changed:

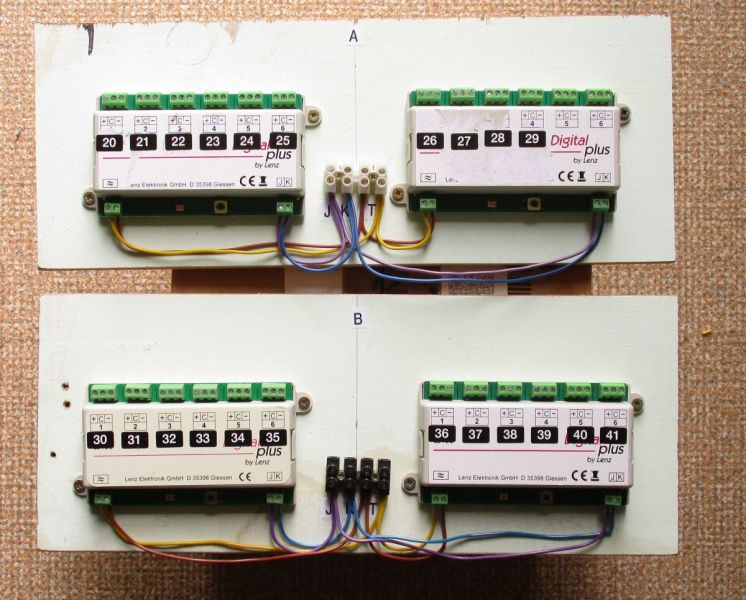

These will be controlled by 2 LS150s mounted on "Board A" and numbered 20 - 29. Points 1 - 19 are located in the storage/fiddle yard on the other side of the unit.

The throat at the "North" end has 12 points, excluding those within the confines of the adjacent MPD, and will be controlled by "Board B", mounted in that area with points numbered 30 - 41. I will need to purchase 2 or 3 new points for this end as my stocks of electrofrog will be exhausted.

The LS150s are mounted on ply boards, 2 per board, ready to attach in a suitable area close to their area of use. Here they all set up ready to fix to the layout and connect to the track bus, transformer and the points themselves.

'Petermac

Posted

Full Member

D

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

As always, your wiring looks very neat. Despite my best intentions, mine looks Mr Squiggle. (Is that another literacy reference I could claim?!)

Regards

Michael

Posted

Full Member

Posted

Full Member

In reality, it's 2 sides of "layout" with the 2 ends simply a means of joining the 2 sides to create a roundy-roundy. When I bought it, each side was a fairly complex station layout with associated sidings and "yards". I dismantled most of 1 side - it was all just too much track and no space for antything else. One side now has the coal yard and new storage/fiddle yards and the other, the original station, turntable and loco depot.

Dave, I do have a couple of PSX circuit breakers but think I'll need more. I haven't got around to sorting out the various power districts yet but I'm estimating I may need 4 of them …………….. You're right in that trhey do indeed help in tracking down problems whilst allowing the rest of the layout to continue as normal. John Dew put me on to them when I was building the original "Maxmill".

'Petermac

Posted

Full Member

Wherever I look, it's "on order"; "pre-order"; "out of stock" - even "actuellement indisponible" (currently unavailable) or, when they are available here in France, at €18.90 a pop, I'm not surprised they have stock !!!

'Petermac

Posted

Full Member

There is a much more cost effective solution to this. Assuming you can get the insulfrogs up (and you will be if you are replacing them) why not just remove the frogs and replace with all metal ones using some code 100 rail a bit of copper clad for the sleepers. You can use the Peco template which is downloadable and printable (Peco use a funny frog angle). It's accurate enough for track construction. Or use aTemplot one to the required angle.There is a very simple technique for frog makibg which I will show in a post later this week. Cost per point around €1.00 (copper clad, flex track rail, solder, wire). You could even replace those pressed point rails and get rid of the closure rail hinge. You could save yourself a lot of money and time.

I've done this with lots of RTR points, Atlas, GF, Peco, ME, Shinohara. Once you have done one it's a breeze. And you are binning them anyway…

Nigel

©Nigel C. Phillips

Posted

Full Member

I'm sure, from what I've heard elsewhere, that hand built points are cheaper than RTR ones per point but there is a certain amount of expenditure on "infrastructure" before you start.

The thing is, I have so many jobs awaiting my attention that I really don't have the time to build points - always assuming I actually wanted to ………………. :roll: :roll:

I think a better option would be to fit stay alives and keep the insulfrog points …………………… I know you think stay-alives have no place on model railways but, from personal experience, I can assure you they have on my layouts !!

It's all a balancing act - the cost of replacing the insulfrog points vs the cost of installing SAs which may well negate the need for electrofrogs.

I have another conundrum today in that one of my replacement electrofrog points had the little spring removed previously - it was probably operated by a Tortoise motor. I have had absolutely no success in replacing it (the spring) - in fact, I can hardly see the darned thing. I had planned to operate these points with SEEP motors but obviously, they need the springs to be in place. Should I replace this point with a new one (ASAP) or buy a Tortoise motor to operate it without the spring ? The motor is the more expensive option but, as I can't actually buy any points at present, the motor could be more expedient ……………………….

I'm rapidly finding that absolutely nothing is plain sailing when working on a layout someone else built ………..

'Petermac

Posted

Full Member

Phil

Posted

Full Member

No, just the frog. I just happen not to like Peco's effort at a switch blade, which is a U shaped pressing.

Replacing the spring needs a good magnifying light. Plus tweezers that have the ends roughed up with some 150 paper. Patience, patience.

As Phil says, building your own is an attractive option. I started out just modifying Shinohara points from power routing to DCC, and getting that oversized gap down between the stock rails and point blades on Peco's offerings. Working in EM means DIY anyway. Plus frog angles I want, not what Peco thinks I should have.

Shame to bin those insulfrogs when 20 minutes work gets you an electrofrog. For about 1/15th of the cost.

Nigel

©Nigel C. Phillips

Posted

Full Member

Oops - the quick and dirty method does not work for code 100. However, I have some code 100 rail (Atlas) that I can shape using a #4 frog jig, and solder up to Peco standard 12°, frog # 4.7) if you are interested in giving it a try. PM me.

Nigel

©Nigel C. Phillips

Posted

Full Member

Would I not need roller gauges and such other mystical things for replacing frogs Nigel ? I'm assuming I'd be replacing the plastic sleeper fret with copper clad …………………. :hmm :hmm

Similarly, wouldn't I require a jig for filing the frog joint accurately ?

However, the idea has some merit and might appeal - only because new points are unavailable at present, you'll understand …………………………………………………… :hmm :hmm :hmm :hmm :hmm

'Petermac

Posted

Full Member

It's all fallen apart it seems ……………..

Why doesn't your "easy" method work with Code 100, especially as you're offering Peco style frogs made up from Atlas Code 100 rail ? Is Atlas rail different from Peco rail and if so, how would I join up with the Code 100 flexitrack after the point ?

I wonder which would arrive first - the necessary jigs to make points or new point supplies. Does anyone know if Peco are manufacturing again yet ?

'Petermac

1 guest and 0 members have just viewed this.