Point motor control for double turnouts in N Gauge

Posted

#229607

(In Topic #12549)

Full Member

Are Cobalts too big?

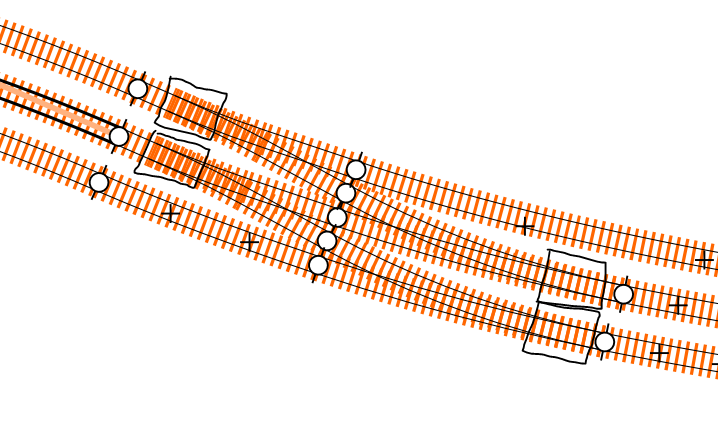

Where you have two parallel tracks at the 6' distance apart and have two turnouts side by side to make a junction like the below… Are Cobalt motors too wide? Looking at this printed out full-size, I am sure it must be a squeeze to get them into position… Has anyone done this? I don't want to start buying expensive motors if they aren't going to fit…

Mike

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Posted

Full Member

Extend the arms using steel rod of the appropriate diameter (dog leg design), and/or use some of the kit used in WIT. Even better, use WIT control and have the Cobalts at the edge in one place. It makes the wiring easier and neater. If you are using Peco turnouts use the hole in the end of the switch bar rather than the one in the center.

Easiest solution is to simply stagger the turnouts by the 1.5 x the length of the Cobalt. Then you can have them all under the respective switch bar.

Is this DC or DCC? Insulfrogs or electrofrogs? Power-routed? (If they're Peco electrofrogs I believe they're power-routed). I was figuring out the wiring for DCC while thinking about the Cobalts. If it's DCC you might want to think about using some frog juicers, it would cut down the wiring.

Nigel

©Nigel C. Phillips

Posted

Full Member

This is going to be DC. I enjoy the traditional side of wiring and also have no budget to get into DCC…

I don't want to stagger the turnouts as cosmetically I love the look of the parallel tracks crossing.

I've always shied away from WIT as it's so far out of my comfort zone. Mechanics, especially dogleg pivots etc. just seem so difficult to understand.

HOWEVER… a fully WIT approach would save a lot of cash, and I am very intrigued about a row of motors changing the points via WIT. It's an excellent idea, thank you… One I think I should give serious thought to. If you have any links to point me to good WIT tutorials or pictures, I'd be grateful…

Mike.

Mike

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Posted

Full Member

Posted

Full Member

Mike

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Posted

Full Member

I'd be looking at WiT or linkages/cranks.

Gormo's Great Chesterford Junction has a really good "how I done it" on mechanical linkages that might give you some ideas and there should be something in the index for WiT.

Cheers

Marty

Posted

Site staff

but yes WIT is the cheapest - I use it as well as Tortoise, Peco below mounted & Peco side mounted solenoids.

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Inactive Member

As Sol has pointed out , probably the easiest way , is to

stagger the motors . Another way ,is to purchase a length

of piano wire from your local model shop. Mount the motors beside

the tracks , replace the existing wire with a new longer wire .Bent with a

dogs leg .

Regards Ted

Posted

Full Member

Mike

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Posted

Site staff

The manual is pretty good.

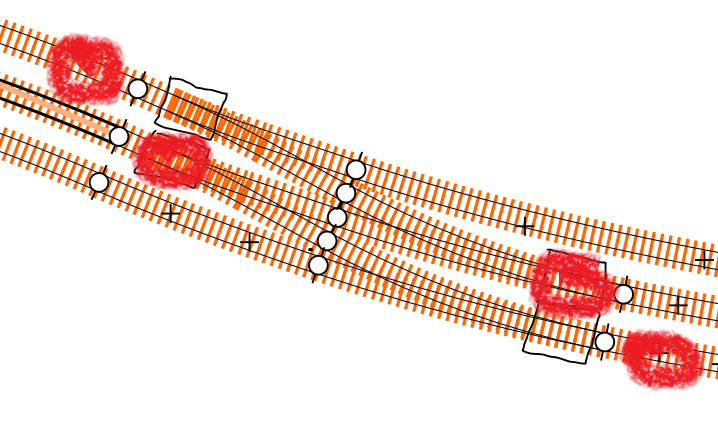

but you not have to have them facing the same way - they can be either side of the tiebar

like this

or this way

Ron

NCE DCC ; 00 scale UK outline.

NCE DCC ; 00 scale UK outline.

Posted

Full Member

Posted

Full Member

Mike

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Posted

Full Member

Posted

Full Member

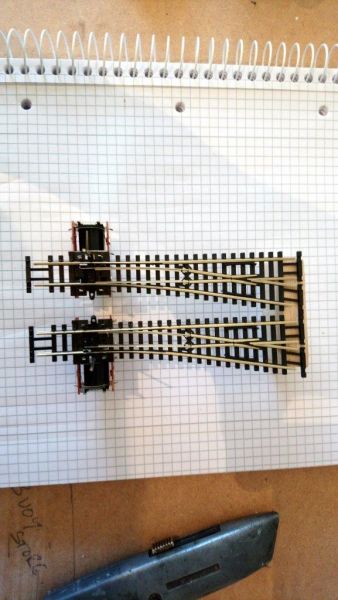

You may be able to offset the Seeps in the same manner as the above photo but because of the alignment requirements you may find the overall length of the Seeps clash in the middle.

I use Seeps and the accessory switch drives a 4 point relay that drives frog polarity, point direction indication on the control panel and a lock out of signal actuation.

Cheers

Marty

Posted

Site staff

Having just got one for the new layout, the switch seems very similar in operation to the Peco Pl-13 switch which I had problems with in the past.

I didn't have the PL-13 directly attached to a point, but operated by a wire attached to a surface mounted PL-11, for changing point indication LEDs.

It may have been my dirty garage environment, but I seemed to be for ever cleaning the contacts on the PL-13s to get them to work.

Ed

Posted

Full Member

Peco point motors are fine it's the peco switches (for frog polarity) that I have found unreliable.Thanks Chris, that is super helpful. I've read recently (John on Granby??) that the Peco motors aren't all that reliable though… How have you found them to be?

I also prefer the quiet zzzzz of a tortoise to the rat a tat tat of a peco motor:lol:

Posted

Inactive Member

Max

Port Elderley

Port Elderley

Posted

Full Member

Just in case you've missed it Mike, have a look at Max's Port Elderly topic.

Cheers

Marty

Posted

Inactive Member

Servos (apart from being very quiet :lol: ), are also very small and can be close coupled and mounted directly under the individual tracks.

I hesitate to mention them, as it requires a different mind set to embrace them.

They work with DC and DCC.

Max

Port Elderley

Port Elderley

Posted

Full Member

Mike

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

Pig Hill Yard - a small Inglenook shunting layout for my boys, in 00.

1 guest and 0 members have just viewed this.