Improved Guillotine

Posted

#122160

(In Topic #6378)

Full Member

What was needed was a thinner blade with a less pronounced bevelled edge. At 8/1000" - 0.02mm a single-edged razor blade was likely to be the answer, but how could it be held securely and at right-angles to a base, given that one edge was nearly 40/1000 thick?

Having faffed about for ages trying to make suitable arm for the guillotine, the answer occurred to me when I discovered that the thick backing to the blade could be simply prised off the blade with the tip of my pocket-knife leaving a flat blade with useful 2.9mm fastening holes!

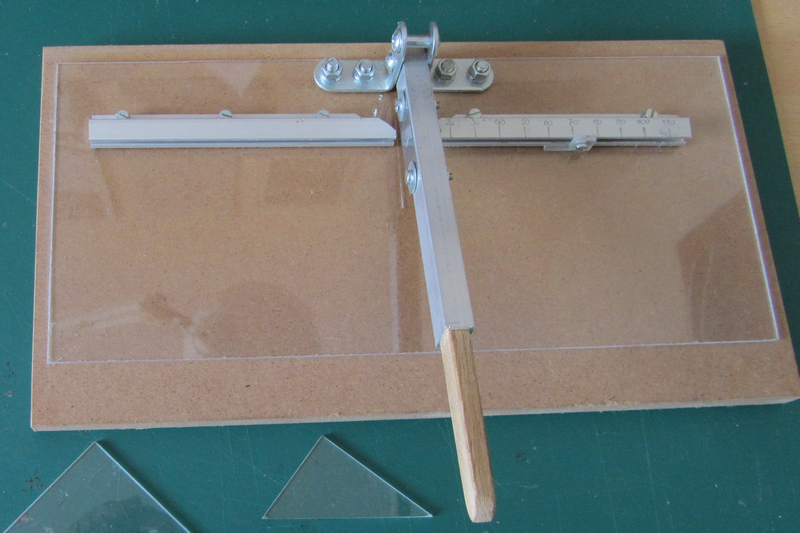

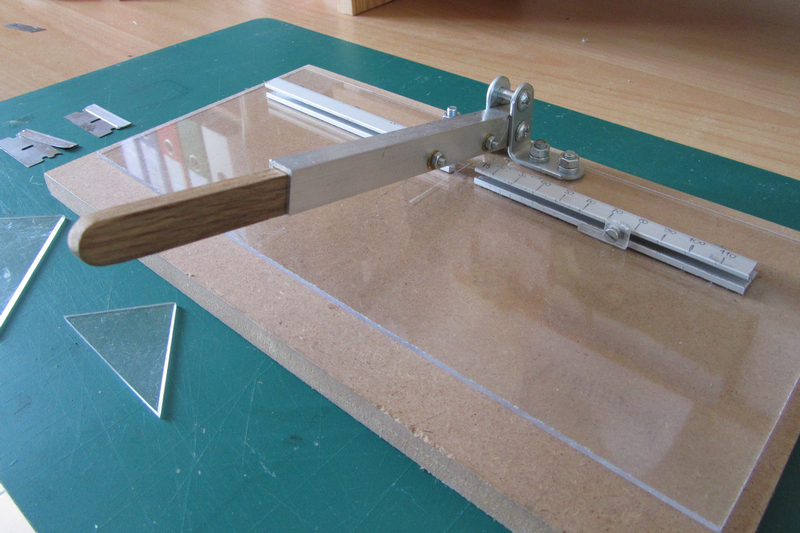

So, using suitably substantial right-angle brackets [ex-B&Q], an M.D.F. base, a Perspex cutting surface, some 10mm x 15mm aluminium channel for the 'arm' and some aluminium channel rescued from a redundant draught-excluder I knocked up the model below with the aid of a few nuts and bolts.

The only noteworthy parts of the construction are

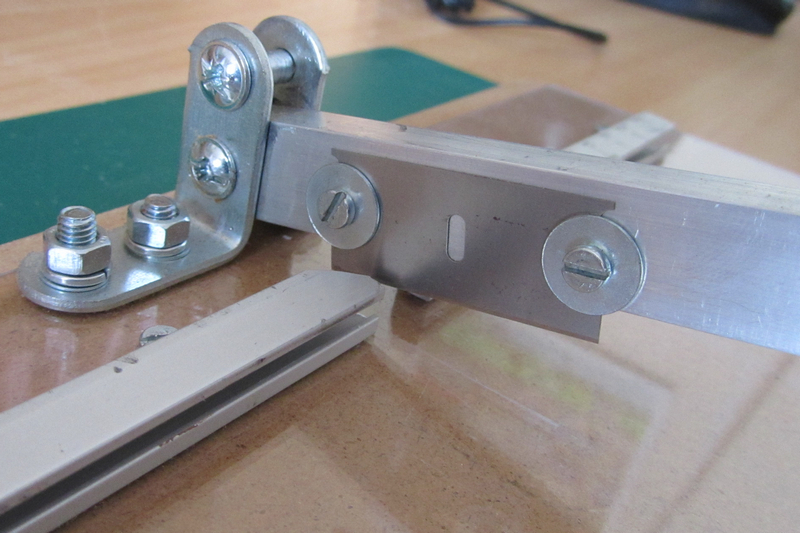

a. the use of two 5mm hollow bolts of the sort used to fasten together adjacent flat-pack bookcases. They have a smooth outer surface and the bracket holes were carefully opened out to accommodate them, a much more satisfactory arrangement than having the arm hinging about the threaded portion of an ordinary machine screw. The upper bolt allows a slight 'nip' to be taken on the arm, obviating any slop in the action.

b. The aluminium channel was fitted throughout its length with a piece of hardwood to both form a handle and to prevent the pivot bolts from crushing the channel out of true squareness.

Before fixing the blade to the arm I set up the left-hand-end guide at right-angles to the lowered arm and then using a straight-edge aligned the right-hand guide to match, a suitable gap left between them for the back edges of the blade.

To mount the blade parallel to the cutting surface I bolted it loosely to the arm, pressed it flat onto the Perspex and then tightened up the mounting screws.

Feeling pretty pleased with the result, I made up a distance stop, dog-legged to reach under the blade and marked off approximate centimetre marks.

In use, the thinner blade gave much better result as shown below, the cut on the left-hand end of the matchstick having been done with the previous 'Snap-off' guillotine, that on the right with the new blade.

All in all, was it worth it? I think so, I needed some quiet time on the workshop and a small absorbing challenge, and this job provided it. I hope it inspires someone else to try it out, too. A little research reveals that still thinner one-sided carbon-steel blades are available and are apparently used in a piece of laboratory equipment called a 'microtome' to take very thin slices of suitably prepared material for microscopic examination in order that light may pass through it to facilitate its examination.

Doug

Last edit: by Chubber

Last edit: by Chubber

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

I'm certainly going to have a go at a version.

Posted

Full Member

Posted

Inactive Member

Max

Port Elderley

Port Elderley

Posted

Guest user

Posted

Full Member

Seriously, that's a very nice, neat job. I have a commercially-made guillotine. The plastic construction allows far too much lateral play in the arm. Something like yours is far superior. :thumbs

Perry

Due to cutbacks, the light at the end of the tunnel has been switched off.

Posted

Guest user

Posted

Guest user

Posted

Full Member

Tell us more ………………….:roll::roll:Just ordered one from the states $48 = £31

'Petermac

Posted

Full Member

I wonder who will be the first to lose a fingertip?

Posted

Full Member

'Petermac

Posted

Full Member

Posted

Full Member

Somewhere out there is a desk with "DD loves ?" carved into it ………….:roll::roll:

'Petermac

Posted

Full Member

I use the styrene tubing for chimneys in all gauges.

Others will know that it tends to compress the top side of the tube if cut in one pass - leaving a sloped edge across the cylinder.

Of course, this can be overcome with care and multiple scoring around the tube but I wondered if anyone has an easier way (or a tool) to make the job faster.

After the accident with Much Wittering, I have quite a few to replace.

Just thinking - I wonder if electrical wire strippers would do the job - I'll try it.

Posted

Full Member

I have three different types and I've tried them all.

Maybe if I introduced a supportive core into the tube it would help.

Posted

Full Member

Doug

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

(I'll pass on the obvious comments about using ordinary erasers to erase soft pencil marks)

I'm not confident of the idea working because of the flimsy nature of the tubes - especially in 'N'.

Posted

Full Member

:thumbs

:thumbsDoug

'You may share the labours of the great, but you will not share the spoil…' Aesop's Fables

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

"Beer is proof that God loves us and wants us to be happy" - Benjamin Franklin

In the land of the slap-dash and implausible, mediocrity is king

Posted

Full Member

It as a V shaped blade in a small hand held guilatine, the pipe sits in a notch and the blade goes into the tube with the point of the V first, in that way it pierces the tube and then cuts with out crushing.

For thicker tubes I have a cheap (Blackspur brand about £3) pipe cutter similar to what plumbers use that does from 3mm upto about 15mm

Cheers

Andy

Andy

1 guest and 0 members have just viewed this.