Tutorial Speed Profiling

Posted

Inactive Member

I need help with CV editing please

What brand is that, Dave? John's talking $100.

Max

Port Elderley

Port Elderley

Posted

Full Member

Apology for hijacking the forum - my next post will be about speed profiling :oops:

Dave there's no worry here about hijacking, i think we are all serial offenders

Stay alive is in an interesting feature unfortunately i am sound chipping mine so the Loksound 4 is an intersting option as they are going to have an add on powerpack although anticipated to be an expensive one.

Zimo sound chips if they ever become available are a much cheaper option because as Max may confirm you just need to piggy back a capacitor.

Regards

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Posted

Full Member

What brand is that, Dave? John's talking $100.

I think John is on about a lenz Gold at $95CDN and i guess Dave is pricing the DCC concepts?

Regards

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Posted

Full Member

[user=269]MaxSouthOz[/user] wrote:

I think John is on about a lenz Gold at $95CDN and i guess Dave is pricing the DCC concepts?What brand is that, Dave? John's talking $100.

Exactly……….quite the difference…………..I got another really helpful email from Richard (DCC Concepts) because I asked about them going into Bachmann Split Chassis………….he sounds like an excellent supplier

Are there rules about hi-jacking

Posted

Full Member

Are there rules about hi-jacking

Ssssh i won't say owt if you don't John, its Easter and i reckon in three days i shall be connecting Stonebridge 2 to TC, getting giddy! that got us back on topic

Regards

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Posted

Full Member

After spending a whole afternoon setting up a loco and then setting up a few blocks so that I could see if I could master the art of profiling and block setup I have got mixed results.

The loco - a class 08 - ( Hornby model ) has a loksound decoder and profiling appeared to go smoothly as Dr Railroad wasn't complaining.

I then setup a schedule so that the loco would run automatically up and down my new profiling track that is made up of three consecutive blocks. John would be proud of me as I even managed to set up a speed indicator which appeared to work as the loco slowed nicely before entering the last block and came to a halt.

However, it is not stopping consistently in the same spot - so I went back into the loco's speed profiling and started adjusting the brake compensation number but without any apparent success - what is the secret ? is it trial and error? or have I messed up something on the wayquest:

Posted

Full Member

Variations in speed have an effect so avoid adjusting block speeds unnecessarily.

To test i run a shuttle from my start block to the stopping block.

Things that can effect performance is slow/poor occupancy detection, when the train enters the stopping block does the block on the screen flash on/off, it it does it can affect braking try using the block memory options. This allows when the block detects the train and shows occupancy instead of a bit if intermittent detection i sometimes get, i can give it a 2 second holding memory which stops my block flashing and helps the with braking stopping measurement Just remeber when the train exits the block it will still show occupancy for two seconds after, this doesn't seem to affect me.

This done by selecting the contact indicator properties for the stopping block and adding some memory time once occupancy is detected.

Is a Class 08 the best runner, i have seen several reports it has pickup problems?

Last edit: by wogga

Last edit: by wogga

Regards

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Posted

Full Member

I'm getting a variance of approx 1cm when I run the class 08 with brake compensation ( which is a very good runner - no problems so far but yes I have heard stories that some are not so good).

A class 56XX loco has a different stopping point and so far variances of 3cm but I have yet to fiddle with the brake compensation.

It must take absolutely ages to get a loco so that it can perform shunting automatically and how do you allow for different locos stopping in the same block?

Posted

Full Member

A class 56XX loco has a different stopping point and so far variances of 3cm but I have yet to fiddle with the brake compensation.

It must take absolutely ages to get a loco so that it can perform shunting automatically and how do you allow for different locos stopping in the same block?

I always do a series of brake tests and for me the profile isnt completed until the loco stops regularly at the 12" test marker…….once a loco has passed this test I fine tune the individual stop marker distances for shunting schedules

I dont worry about "safety" or buffer stop markers I just make sure the distance will allow a bit of tolerance between locos. I use Kaydee magnets which are admittedly unsightly but at 2" long do allow for variations up to approx 3/4" or 2cm when uncoupling

I have a shunting routine for the pick up goods which involves 18 schedules so yes it takes a while to set up and test each schedule……I do have a designated loco for this (Collet Goods) but the terminus loco exchange involves three different locos and works pretty well.

It isnt absolutely perfect every time……thats why some people use IR dots and Max is "investing" in vans with built in decoders but I have found, with patience and a ruthless approach to poor running locos, it works most of the time…..

I have noticed occasionally that a loco seems to need a couple of warm up runs before it will stop where expected

Regards

Posted

Full Member

What John said and i find the brake compensation as the differenciater between engines. I use the same block to set up my brake compensation for each loco, then they seem to work satisfactory in other blocks.

Dave i would be happy with the 1cm for the class 08, when i do my uncoupling it will either be over a ramp or kadee magnet so there is some tolerance.

It's up to you mate, speed profiling can be dull it turned JD into a lover of jazz music!

Last edit: by wogga

Last edit: by wogga

Regards

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Pete.

ECOS2 with RR&Co Traincontroller and a load of other electronics so i can sit back and watch the trains go by.

Posted

Inactive Member

I'd be interested to know if you're using sound decoders. Just to make you feel better, I'm experiencing variances of up to 50mm. It does help to warm the loco up with a few laps of the main layout, but it doesn't help very much.

Max

Port Elderley

Port Elderley

Posted

Full Member

Hi Max,Dave, I still find stopping the loco on the spot extremely unreliable. I have put it down to using sound decoders in conjunction with TC. The longer the block, the more erratic the stopping point is. As John says, I'm going to have a go with DCC uncoupling wagons, when they get here.

I'd be interested to know if you're using sound decoders. Just to make you feel better, I'm experiencing variances of up to 50mm. It does help to warm the loco up with a few laps of the main layout, but it doesn't help very much.

Both of the locos have been "speed profiled" have sound decoders fitted. The class 56xx has proved to be harder to set up than the O8 shunter and I have patiently run through the speed profiling process three times in an endeavour to get more consistent stopping. ( I selected these locos as the sound decoders do give really good control and there was the added bonus of setting up sound functions but I haven't got around to that bit of learning as yet)

Based on your experience I will now try and speed profile a loco without a sound decoder - I have a wide range of locos fitted with different types of decoders - Lenz, NCE, TCS, Hornby, Bachmann 21 pin most of which give good running although I have a feeling that speed profiling may sort the "men from the boys"

My previous attempts about a year ago where with a few locos fitted with NCE decoders and now that I have set things up properly I will have to re-profile them so I'll give a loco with the TCS a go next - I'll let you know how I go and I'll try Richards DCC loco decoder when they arrive .

Any thoughts on whether I should leave BEMF on or off ??

Posted

Full Member

Pete,Things that can effect performance is slow/poor occupancy detection, when the train enters the stopping block does the block on the screen flash on/off, it it does it can affect braking try using the block memory options. This allows when the block detects the train and shows occupancy instead of a bit if intermittent detection i sometimes get, i can give it a 2 second holding memory which stops my block flashing and helps the with braking stopping measurement Just remember when the train exits the block it will still show occupancy for two seconds after, this doesn't seem to affect me.

This done by selecting the contact indicator properties for the stopping block and adding some memory time once occupancy is detected.

My apology for not responding to your advice re poor occupancy detection. Thanks for the advice - I have one block where the detection is poor despite me putting a few extra loops of wire around the detector. ( I have found the NCE detectors very reliable and normally rely on one loop of the wire) The block was in a section were I have a PSX-AR Auto Reverser - the use of the memory seems to have done the trick.:thumbs

To date all my testing and block setup has been on the new installed and easy accessible speed profiling hidden siding ( although at the moment it s not hidden exclam: ) Once I have it mastered I have a lot of block setup to do….

Posted

Inactive Member

I have never had to alter the BEMF on any Loksound decoder.

I should also explain that when it's on the profiling track, the decoder stops the loco pretty much on the spot. It's when the loco has to stop on a spot after travelling a long way that it becomes erratic. Typically, the loco runs about 2.5 metres to where the magnet is and can be up to 25mm either side of the middle of the magnet on successive runs.

When on the short side of the layout, it's only running about 1100mm and the error margin drops to about 15mm either side of the middle of the magnet. Either way, it's too much error.

Initially I thought that TC actually measured the distance along the track, but it only pretends to measure it; relying on speed/time to calculate it. I believe that the time factor is where the problem is and I suspect that because my sound projects are complicated, it doesn't take much for small, differing errors to be amplified by the long distance (time) the loco is having to travel.

I hope that all makes sense. The test will be when you actually run the loco to brake and stop markers on your main layout. If you can get the sound decoder to comply in that scenario, then you will have cracked it. :thumbs

Max

Port Elderley

Port Elderley

Posted

Full Member

When running a schedule the loco is stopping with reasonable consistency but the running behaviour is completely -different even though I have not altered the speed markers - looks like I have another variable to cater for.

Posted

Full Member

Thanks Max,Hi Dave.

I have never had to alter the BEMF on any Loksound decoder.

I should also explain that when it's on the profiling track, the decoder stops the loco pretty much on the spot. It's when the loco has to stop on a spot after traveling a long way that it becomes erratic. Typically, the loco runs about 2.5 metres to where the magnet is and can be up to 25mm either side of the middle of the magnet on successive runs.

When on the short side of the layout, it's only running about 1100mm and the error margin drops to about 15mm either side of the middle of the magnet. Either way, it's too much error.

Initially I thought that TC actually measured the distance along the track, but it only pretends to measure it; relying on speed/time to calculate it. I believe that the time factor is where the problem is and I suspect that because my sound projects are complicated, it doesn't take much for small, differing errors to be amplified by the long distance (time) the loco is having to travel.

I hope that all makes sense. The test will be when you actually run the loco to brake and stop markers on your main layout. If you can get the sound decoder to comply in that scenario, then you will have cracked it. :thumbs

My limited experience with my Loksound decoders appears to be replicating yours - albeit I am still in the early learning stages and have not yet tried any actual shunting - I'm just using markers on the track to measure consistency.

I'm using the standard sound projects that come with the decoder - my initial thoughts were that apart form the sound the other difference is that the sound decoders have momentum settings ( I assume these go hand in glove with the sound settings) and maybe these were causing an issue for the software. That said my latest experience with a TCS decoder raises more questions about my block setups and heres me thinking I was close to being qualified to take off the RR&Co L plates:shock:

Posted

Inactive Member

Max

Port Elderley

Port Elderley

Posted

Full Member

When running a schedule the loco is stopping with reasonable consistency but the running behaviour is completely -different even though I have not altered the speed markers - looks like I have another variable to cater for.

One of the fascinating things about TC is that there are usually 3 or 4 ways of solving a problem…….when it comes to speed control the downside is that there are so many ways that you can set speed limits

Your loco has a max speed……as does each block……you also have the option to set speeds for both settings on a turnout. Within a schedule you can set speed limits for specific blocks or routes and finally you can trigger speed changes with indicators

I have got into trouble a few times by forgetting that a global speed limit on points can have all manner of implications for other schedules

You may want to set one basic test schedule…….maybe just 3 blocks…….determine the speeds you want and work out what settings need to be changed to achieve the result that you want…………happy to help if required

Regards

Posted

Full Member

Hi John,[user=540][/user]

One of the fascinating things about TC is that there are usually 3 or 4 ways of solving a problem…….when it comes to speed control the downside is that there are so many ways that you can set speed limits

Your loco has a max speed……as does each block……you also have the option to set speeds for both settings on a turnout. Within a schedule you can set speed limits for specific blocks or routes and finally you can trigger speed changes with indicators

I have got into trouble a few times by forgetting that a global speed limit on points can have all manner of implications for other schedules

You may want to set one basic test schedule…….maybe just 3 blocks…….determine the speeds you want and work out what settings need to be changed to achieve the result that you want…………happy to help if required

Regards

I hadn't realised that you could set speeds on turnouts until I read your post I can see how a low limit could lead to some unusual ( and potentially frustrating) running if you had forgotten that you had set a limit. As you say there are so many ways of solving (and creating) solutions or problems to be solved

- as a matter of interest what is the difference operationally between setting a maximum speed and a restricted speed?

So far I have limited all my programming of blocks to the three new ones that I put in place (bolted on) to the side of my layout. - The now infamous "hidden siding".

I'm going to have a play with the momentum settings for the Class 37 ( the one with the ) to see if I can get more realistic operation from it.

I must confess that I'm finding these challenges addictive although I mindful that I still have a normal life to lead ( fortunately its the Easter/Anzac long weekend - and its raining so the garden and the outdoors are not their normal distraction.

:cheers

Posted

Full Member

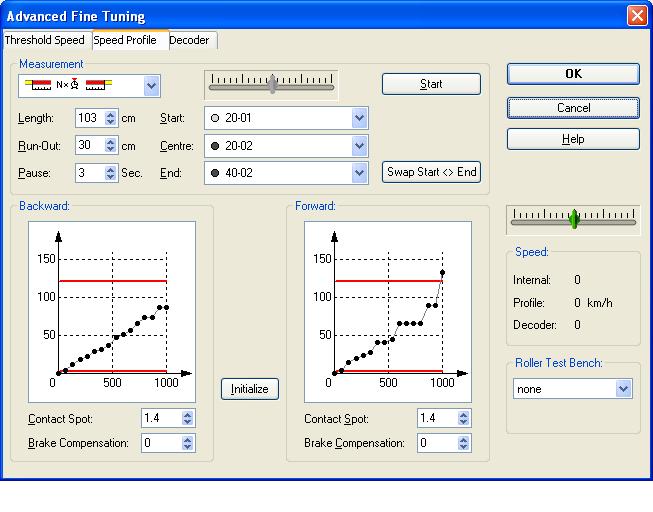

This is the profile for the ViTrains Class 37 with a TCS 2 function decoder. I reset the decoder to factory settings and set CV5 to 200.

Any theories as to the bizarre profile for the Forward speed curve ? The loco appears to be running normally

Last edit: by gdaysydney

Last edit: by gdaysydney

1 guest and 0 members have just viewed this.